laboratory presses

Discover Hench Technology’s range of precision laboratory presses, designed for efficient sample preparation and reliable performance. For inquiries or quotes, contact us today.

-

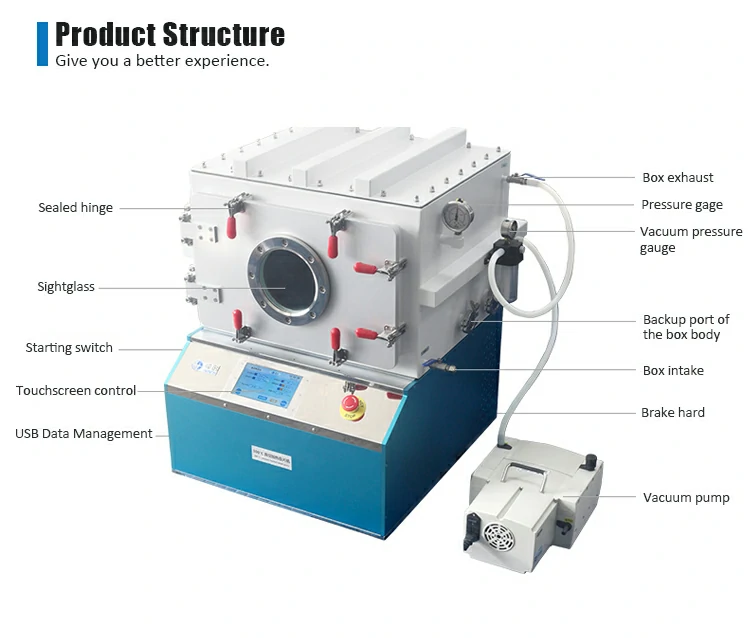

Vacuum Box Automatic Laboratory Hot Press VHP

Vacuum Box Automatic Laboratory Hot Press VHP Features

VHP Vacuum automatic hot press is hot press plate and real Close combination of Vacuum housing, vacuum degree up to -0.95Mpa, full Satisfy the user's experimental needs in a vacuum environment.

Product specification

- Explain:Can be customized, optional vacuum pump

- Flushable air source:Helium, neon, argon, nitrogen, krypton, xenon, radon and other inert gases

- High temperature safety:When the die temperature exceeds 50'℃, the thermostat automatically prompts "Pay attention to anti-hot".

- Pressure safety:Program pressure mechanical fault report emergency stop function, automatic pressure relief + emergency stop switch.

- Hot press plate type:Four-column positioning thermal insulation design, upper plate screw suspension design/electroplated polished panel.

- Soaking time:No time limit, reach the set temperature to stop heating.

- Temperature control systenm:Programmable-5-stage heating-automatic heating automatic insulation - natural cooling.

- Touch screen module:Pressure system - Temperature control system - Data management -English interface interchange.

- Control panel:7 inch LCD touch screen/English interface can be switched.

- Die pressure conversion:PCB control program automatically converts to display sample pressure (Mpa). This makes the VHP an advanced vacuum hydraulic press ideal for precise experimental requirements.

- Dwell time:Not limited to N seconds, each period can be set a different pressure holding time.

- Pressurization process:Programmable - 5-stage automatic pressure - automatic pressure retention - precise pressure - timed pressure relief.

Applications

The VHP series hot press is widely used in materials science, chemical synthesis, polymer development, optical films, and resin molding. Its programmable heating and pressurization system makes it one of the most reliable hydraulic press machine options for laboratory environments that demand accuracy and repeatability.

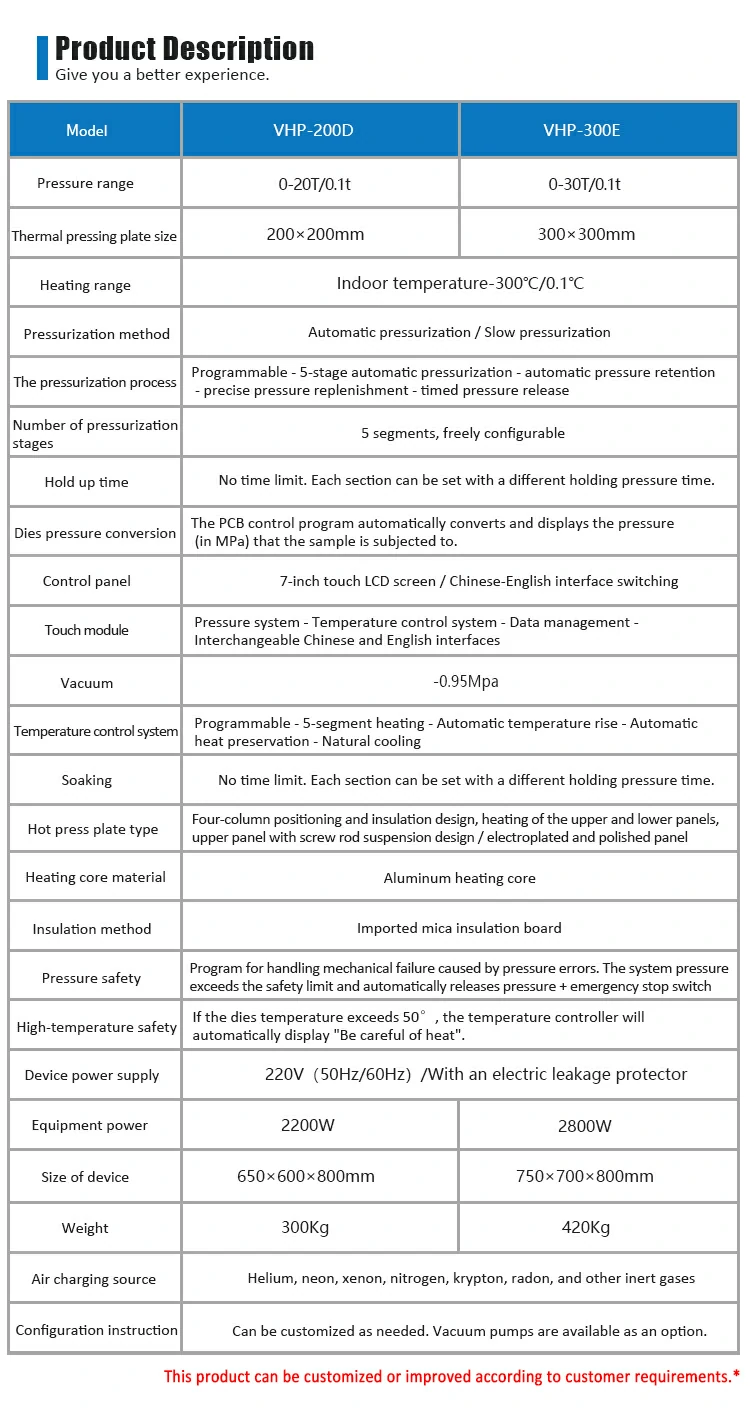

Product Description

Model VHP-200D VHP-300E Pressure range 0-20T / 0.1t 0-30T / 0.1t Thermal pressing plate size 200×200mm 300×300mm Heating range Indoor temperature - 300℃ / 0.1℃ Pressurization method Automatic pressurization / Slow pressurization The pressurization process Programmable - 5-stage automatic pressurization - automatic pressure retention - precise pressure replenishment - timed pressure release Number of pressurization stages 5 segments, freely configurable Hold up time No time limit. Each section can be set with a different holding pressure time. Dies pressure conversion The PCB control program automatically converts and displays the pressure (in MPa) that the sample is subjected to. Control panel 7-inch touch LCD screen / Chinese-English interface switching Touch module Pressure system - Temperature control system - Data management - Interchangeable Chinese and English interfaces Vacuum -0.95Mpa Temperature control system Programmable - 5-segment heating - Automatic temperature rise - Automatic heat preservation - Natural cooling Soaking No time limit. Each section can be set with a different holding pressure time. Hot press plate type Four-column positioning and insulation design, heating of the upper and lower panels, upper panel with screw rod suspension design / electroplated and polished panel Heating core material Aluminum heating core Insulation method Imported mica insulation board Pressure safety Program for handling mechanical failure caused by pressure errors. The system pressure exceeds the safety limit and automatically releases pressure + emergency stop switch High-temperature safety If the dies temperature exceeds 50℃, the temperature controller will automatically display "Be careful of heat". Device power supply 220V (50Hz/60Hz) / With an electric leakage protector Equipment power 2200W 2800W Size of device 650×600×800mm 750×700×800mm Weight 300Kg 420Kg Air charging source Helium, neon, xenon, nitrogen, krypton, radon, and other inert gases Configuration instruction Can be customized as needed. Vacuum pumps are available as an option. This product can be customized or improved according to customer requirements.

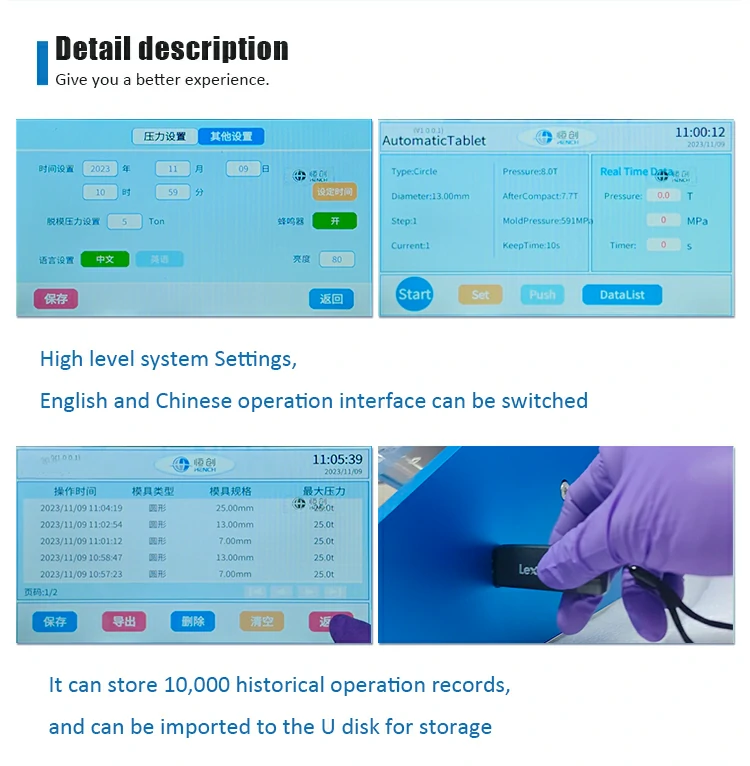

Detail Description

- High-level system settings, with switchable English and Chinese operation interfaces.

- Can store up to 10,000 historical operation records, which can be exported to a USB disk for storage.

Operation Interface

- Setting

Under the operation interface, press Settings to enter the setting interface. Here you can set pressure, mold type, and sample parameters. - Demould

Press the Release button to start. When the pressure exceeds the specified value or the limit switch is triggered, the device will automatically stop and relieve pressure. Manual screw operation is also available. - Data Administration

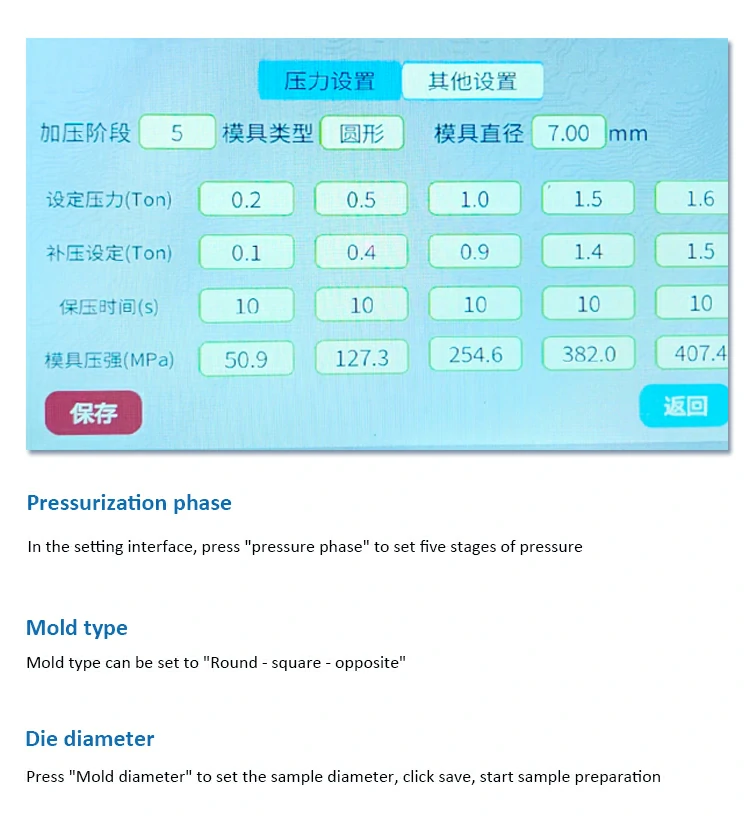

Press Data Management to view experimental parameters and time records. Data can be exported to a USB disk. - Pressurization Phase

In the setting interface, press Pressure Phase to configure up to five stages of pressure. - Mold Type

The mold type can be set to Round, Square, or Opposite. - Die Diameter

Press Mold Diameter to set the sample diameter, then click Save to start sample preparation.

Why Choose Hench?

Hench Technology Co., Ltd., headquartered in Tianjin, China, is a professional manufacturer of laboratory hot presses, infrared sample preparation systems, and customized vacuum press solutions. With over a decade of expertise, Hench has established itself among leading hydraulic press suppliers, offering customers tailored solutions backed by strong R&D and strict quality control.

Hench provides reliable solutions with professional technical support and after-sales service. We emphasizes innovation, safety, and user-friendly design, ensuring that every piece of equipment delivers stable performance for universities, research institutes, and industrial laboratories.

-

Fully Automatic Heating Laboratory Tablet Press HZT-800E/F/G

Fully Automatic Heating Laboratory Tablet Press Features

ZHT series hot press adopts integrated structure,from dynamic hydraulic drive, four-column positioning heat insulation Settings, lead screw suspension the hot plate is hoisted, with fast pressure,easy to operate ad vantages such as maintenance. Multi-stage temperature control can meet a variety of powder, plastic thin mem brane, rubber material and its solid material for high temperature high repressed-like user use.

Key Features

-

Models & Pressure: Available in 0-30T / 0-40T variants.

-

Piston Diameter & Stroke: Options with 110mm / 130mm pistons, stroke ≈ 55 mm.

-

Temperature & Heating Range: Room temperature up to 600 °C; heating range options up to 300 °C or 500 °C depending on configuration.

-

Die Size & Effective Space: Die plate dimensions of 300×300 mm, 400×400 mm, or 600×600 mm; effective working height around 65 mm.

-

Power, Size & Weight: Models use from 3 kW up to 12.5 kW power; machine dimensions scale (e.g. 400×500×750 mm up to 700×800×1110 mm); weights between ~350 kg to ~450 kg depending on size.

Product Advantages

-

Fully automatic press with integrated structure, four-column positioning and heat insulation. Hot plate is suspended by lead screws, enabling smooth lifting, fast pressure application, and easier maintenance.

-

Multi-stage temperature control accommodates a variety of materials: powders, plastics, thin membranes, rubbers, or other solid samples that require high temperature and consistent pressure.

Product Description

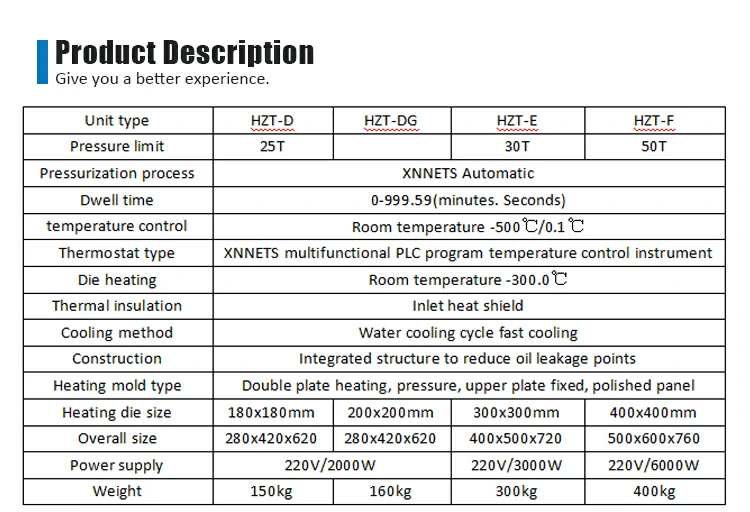

Unit type HZT-D HZT-DG HZT-E HZT-F Pressure limit 25T 30T 50T Pressurization process XNNETS Automatic Dwell time 0-999.59 (minutes. Seconds) Temperature control Room temperature - 500℃ / 0.1℃ Thermostat type XNNETS multifunctional PLC program temperature control instrument Die heating Room temperature - 300.0℃ Thermal insulation Inlet heat shield Cooling method Water cooling cycle fast cooling Construction Integrated structure to reduce oil leakage points Heating mold type Double plate heating, pressure, upper plate fixed, polished panel Heating die size 180×180mm 200×200mm 300×300mm 400×400mm Overall size 280×420×620 280×420×620 400×500×720 500×600×760 Power supply 220V / 2000W 220V / 3000W 220V / 6000W Weight 150kg 160kg 300kg 400kg Operating Steps

-

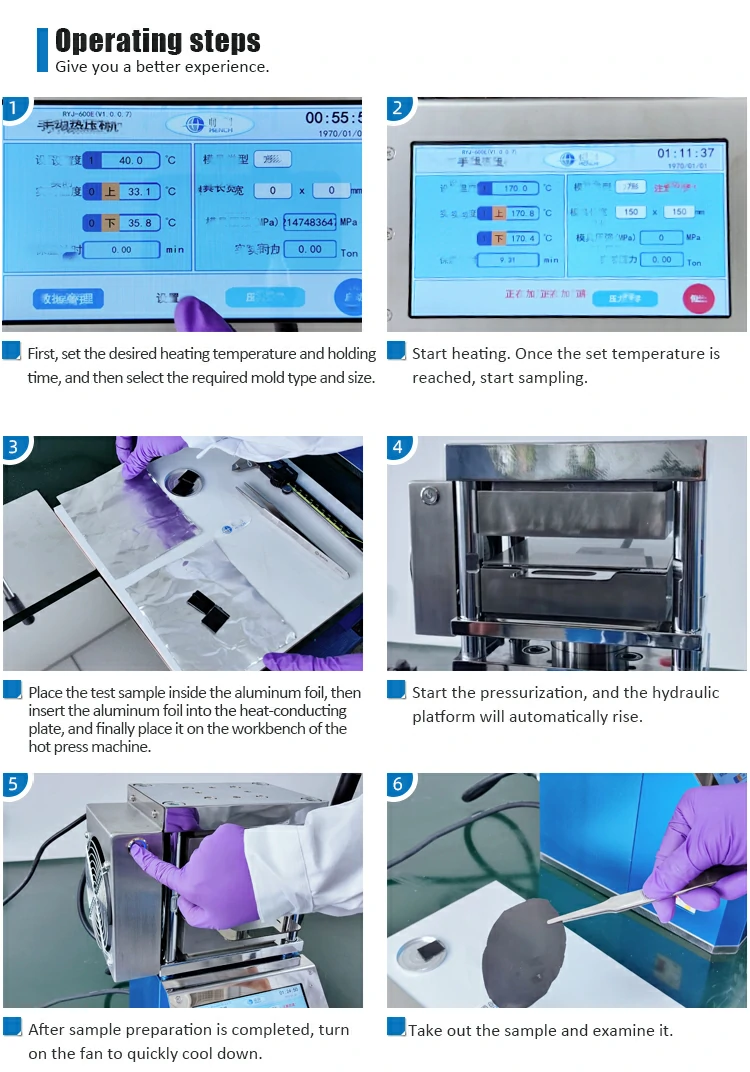

First, set the desired heating temperature and holding time, and then select the required mold type and size.

-

Start heating. Once the set temperature is reached, begin sampling.

-

Place the test sample in the aluminum foil, then insert the foil into the heat-conducting plate, and finally place it on the workbench of the hot press machine.

-

Start pressurization, and the hydraulic platform will automatically rise.

-

After sample preparation is complete, turn on the fan to cool it down quickly.

-

Take out the sample and examine it.

Why Choose Hench?

Hench Technology Co., Ltd., based in Tianjin, China, specializes in manufacturing high-precision lab equipment including heating tablet presses, infrared sample preparation systems, and full ranges of hydraulic press solutions. They are recognized among leading hydraulic press suppliers for combining robust engineering with tailored customer support.

Hench’s product offerings include state-of-the-art hydraulic press machine models as well as specialized hydraulic heat press machine lines. Their machines are designed with safety, repeatability, and ease of operation in mind—making them a strong partner for both academic and industrial users.

-

-

Fully Automatic Laboratory Heat Press HZT-800D/DG

Fully Automatic Laboratory Heat Press HZT‑800D/DG

- Temperature control die:5 stages adjustable continuous temperature control - automatic heating - automatic insulation natural cooling

- Control pressure and temperature:0.1T/0.1°C(Customizable accuracy)

- Soaking time:No time limit, reach the set temperature to stop heating

- Display usage:7 inch LCD touch screen/English interface can be switched

- Die pressure conversion:PCB control program automatically converts to display sample pressure (Mpa)

- Heating plate type:Four-column positioning thermal insulation design, upper plate screw suspension designyelectroplated polished panel

- Heating core material:Aluminum heating core/Copper heating core

- Heat insulation method:lmported mica heat insulation board

- Cooling method:Standard wall hanging air cooler

- Passive safety:With leakape protection+emergency stop switch

- Security configuration:Program pressure mechanical failure error emergency stop function, die more than 50'℃, prompt "pay attention to antihot"

- Explain:The control panel size can be customized to increase the width and the column height.

Design & Control Advantages

-

A 7‑inch LCD touch screen allows precise control of both pressure and temperature, delivering repeatable results in research or industrial labs.

-

Safety features include emergency stops, mechanical fault alarms, over-temperature warnings, and an air-cooling system, ensuring reliability during continuous lab operations.

-

Its integrated design and adjustable soaking time make it a preferred choice among advanced hydraulic heat press machines, where controlled heating and pressing are critical.

Applications

Widely used for tablet or pellet preparation, thermo-plastic testing, infrared spectroscopy samples, or any research requiring precise heating under pressure.

Product Description

Unit type HZT-D HZT-DG HZT-E HZT-F Pressure limit 25T 30T 50T Pressurization process XNNETS Automatic Dwell time 0-999.59(minutes. Seconds) temperature control Room temperature -500℃/0.1℃ Thermostat type XNNETS multifunctional PLC program temperature control instrument Die heating Room temperature -300.0℃ Thermal insulation Inlet heat shield Cooling method Water cooling cycle fast cooling Construction Integrated structure to reduce oil leakage points Heating mold type Double plate heating, pressure, upper plate fixed, polished panel Heating die size 180x180mm 200x200mm 300x300mm 400x400mm Overall size 280x420x620 280x420x620 400x500x720 500x600x760 Power supply 220V/2000W 220V/3000W 220V/6000W Weight 150kg 160kg 300kg 400kg Operating Procedure

-

First, set the desired heating temperature and holding time, and then select the required die type and size.

-

Start heating. Once the set temperature is reached, begin sampling.

-

Place the test sample inside the aluminum foil, then insert the aluminum foil into the heat-conducting plate, and finally place it on the workbench of the hot press machine.

-

Start pressurization, and the hydraulic platform will automatically rise.

-

After sample preparation is completed, turn on the fan to cool down quickly.

-

Take out the sample for examination.

Why Choose Hench?

Hench based in Tianjin, China, is a leading hydraulic press manufacturer specializing in laboratory hot presses, hydraulic heating systems, and precision sample preparation equipment. Hench designs reliable lab supplies that balance performance, safety, and ease of use. Their solutions are trusted worldwide in research institutes, universities, and industrial laboratories.

-

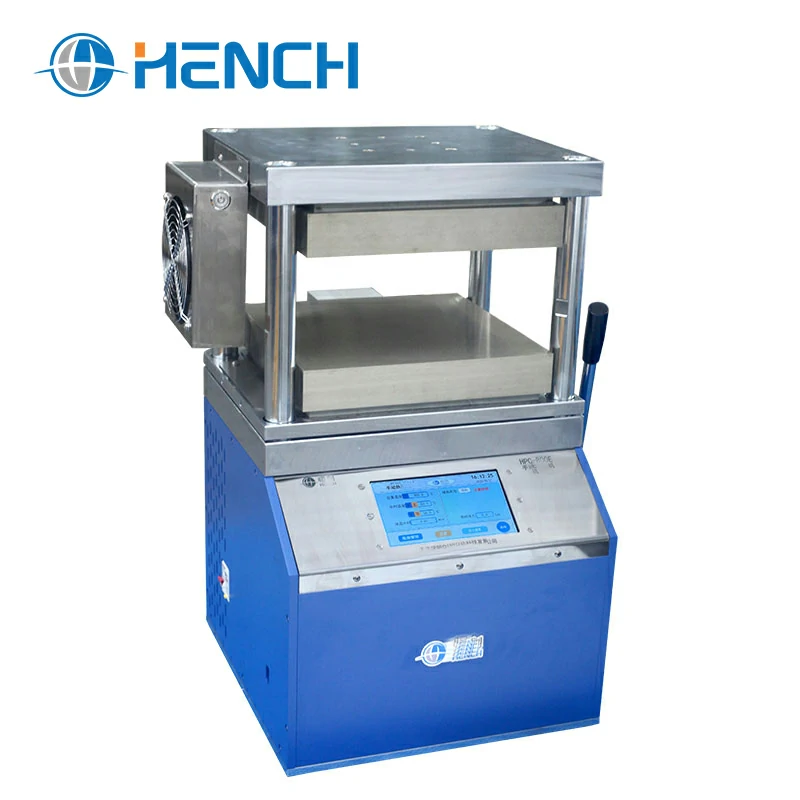

Manual Integrated Hot Hydraulic Press HPC-800E/F

Manual Integrated Hot Hydraulic Press Features

HPC series manual integrated hot press is small tonnage, widened type, unibody, double plate hot pressing sheet machine,to meet the pressure control accuracy is more strict, and need wide size die sample test,can also be as a small vulcanization instrument used, has been widely used in the department research,teaching, pharmaceutical catalytic, chemical and other industries,can replace similar imported products.

Design & Control Advantages

-

The press combines heating and hydraulic pressing in a single integrated structure, offering uniform pressure distribution and excellent heat transfer.

-

A simple, intuitive control interface makes it accessible for lab technicians or production staff while maintaining high accuracy. This level of precision is typical of advanced hydraulic press machines.

-

Safety features include mechanical fault alarms, over-temperature protection, and emergency stop, ensuring reliable and secure operation in daily use.

Applications

Ideal for pressing powders, polymers, rubbers, or composite samples in research labs, R&D departments, and small-scale industrial production. The HPC‑800E/F ensures consistent quality and repeatability, reflecting the expertise of established hydraulic press manufacturers.

Operating Procedure

-

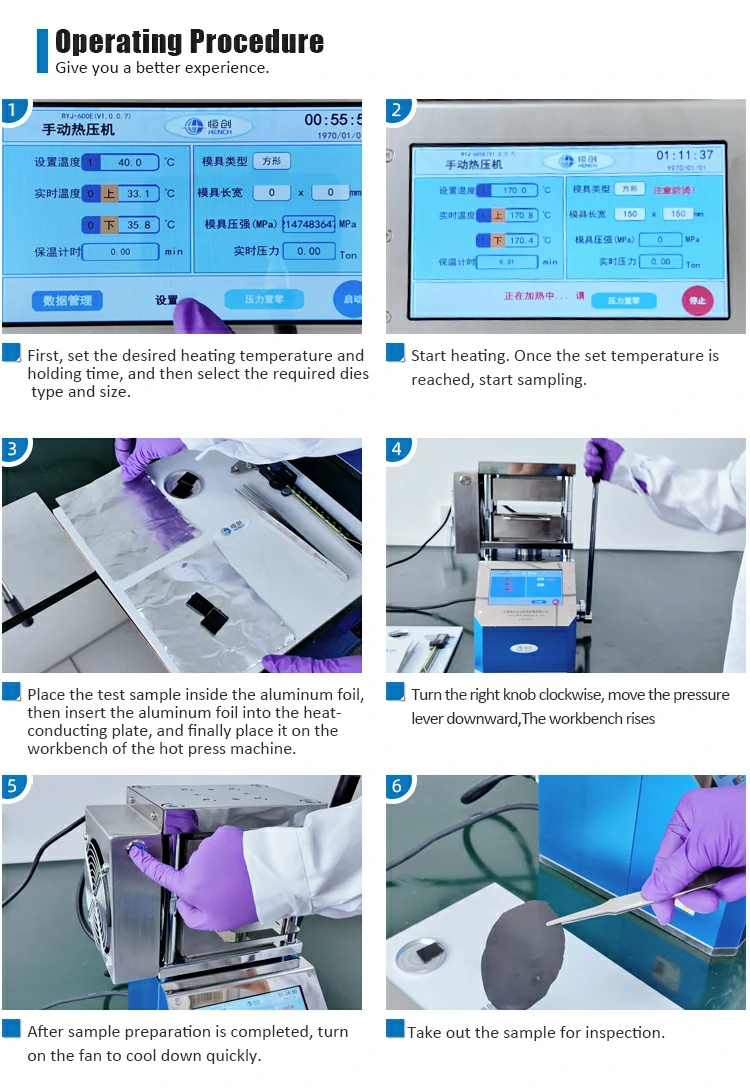

First, set the desired heating temperature and holding time, and then select the required die type and size.

-

Start heating. Once the set temperature is reached, begin sampling.

-

Place the test sample inside the aluminum foil, then insert the aluminum foil into the heat-conducting plate, and finally place it on the workbench of the hot press machine.

-

Turn the right knob clockwise to move the pressure lever downward, causing the workbench to rise.

-

After sample preparation is completed, turn on the fan for rapid cooling.

-

Take out the sample for inspection.

Why Choose Hench?

Hench Technology Co., Ltd., headquartered in Tianjin, China, specializes in precision laboratory and industrial presses, including heated and hydraulic solutions. Hench is recognized for designing reliable heated hydraulic presses, combining safety, performance, and ease of use. Their products serve laboratories, universities, and industrial clients worldwide, backed by professional support and rigorous quality standards.

-

-

Manual Integrated Heating Tablet Press Machine HPC-800D/DG

Manual Integrated Heating Tablet Press Machine

The HPC‑800D/DG is a precise, compact tablet press machine designed for laboratory and small-scale production, combining manual control with reliable heating and pressing.

- Temperature control:5 stages adjustable continuous temperature control - automatic heating - automatic insulation - natural cooling

- Heating range:300°C(D1、D2、E、F)/500°(DG1、DG2、EG、FG)

- Dwell time:Unlimited time (manual pressure relief)

- Display usage:7 inch LCD touch screen/English interface can be switched

- Die pressure conversion:PCB control program automatically converts to display sample pressure (Mpa)

- Heating plate type:Four-column posiltioning thermal insulation design, upper plate screw suspension desien/electroplated polished banel

- Heating core material:300'CAluminum heatingcore (D1、D2、E、F)/500"c Copper heatingcore (DG1、DG2、EG、FG)

- Heat insulation method:Imported mica heat insulation board

- Cooling method:Standard wall hanging air cooler

- Passive safety:With leakage protection + emergency stop switch

- Security confguration:Optional 110V die temperature over 50℃, thermostat automatically prompts "pay attention to anti-hot"

- Input Power:220V(50Hz/60Hz)/110V is available

- Explain:The control panel size can be customized to increase the width and the column height.

Design & Control Advantages

-

Integrated heating and hydraulic pressing provide even pressure distribution and accurate temperature control.

-

Simple control interface allows lab technicians to set pressure and temperature precisely, reflecting the high standards of advanced hydraulic press machines.

-

Safety features include mechanical fault alarms, emergency stop, and over-temperature protection, ensuring secure and reliable operation.

Product Description

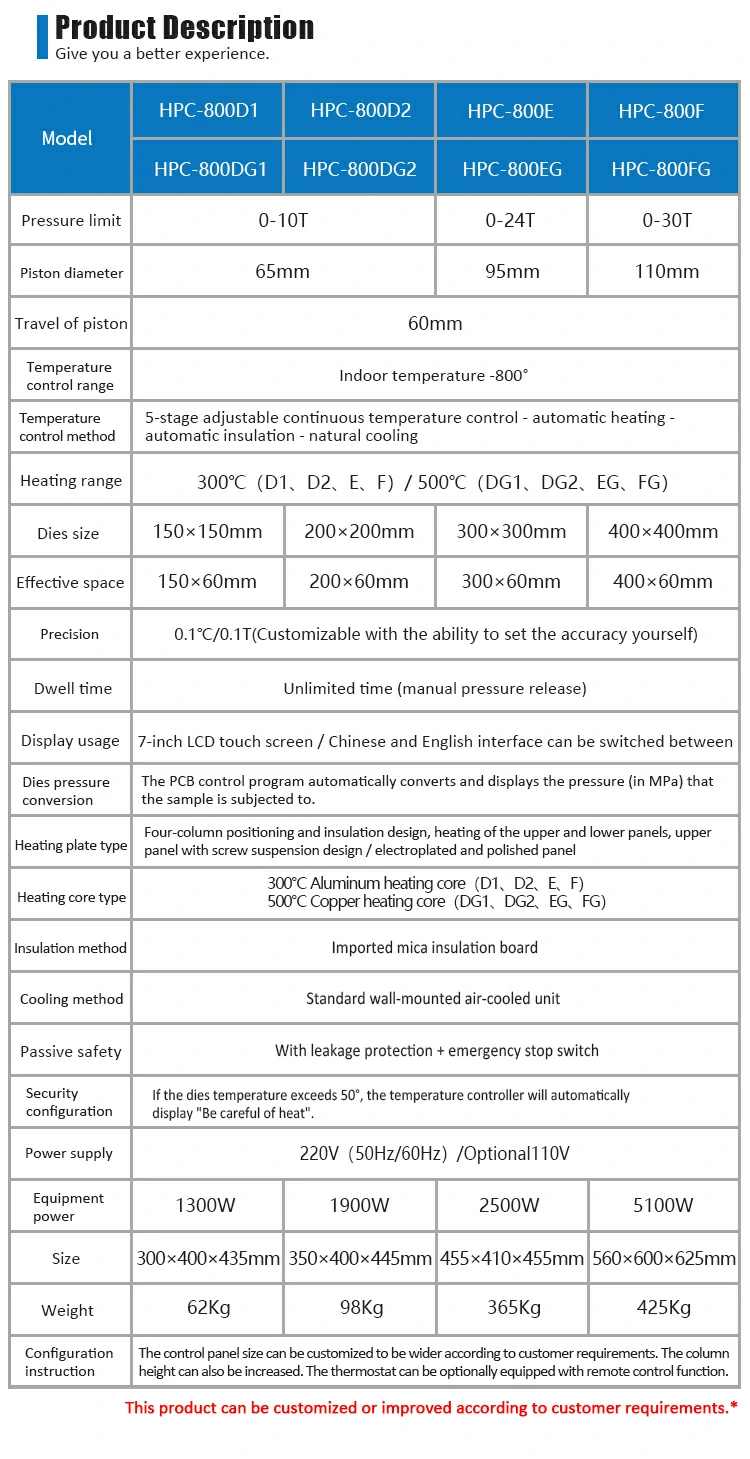

Model HPC-800D1 HPC-800D2 HPC-800E HPC-800F HPC-800DG1 HPC-800DG2 HPC-800EG HPC-800FG Pressure limit 0-10T 0-24T 0-30T Piston diameter 65mm 95mm 110mm Travel of piston 60mm Temperature control range Indoor temperature -800° Temperature control method 5-stage adjustable continuous temperature control - automatic heating - automatic insulation - natural cooling Heating range 300°C (D1, D2, E, F) / 500°C (DG1, DG2, EG, FG) Dies size 150×150mm 200×200mm 300×300mm 400×400mm Effective space 150×60mm 200×60mm 300×60mm 400×60mm Precision 0.1°C/0.1T(Customizable with the ability to set the accuracy yourself) Dwell time Unlimited time (manual pressure release) Display usage 7-inch LCD touch screen / Chinese and English interface can be switched between Dies pressure conversion The PCB control program automatically converts and displays the pressure (in MPa) that the sample is subjected to. Heating plate type Four-column positioning and insulation design, heating of the upper and lower panels, upper panel with screw suspension design / electroplated and polished panel Heating core type 300°C Aluminum heating core (D1, D2, E, F) 500°C Copper heating core (DG1, DG2, EG, FG)

Insulation method Imported mica insulation board Cooling method Standard wall-mounted air-cooled unit Passive safety With leakage protection + emergency stop switch Security configuration If the dies temperature exceeds 50°, the temperature controller will automatically display "Be careful of heat". Power supply 220V (50Hz/60Hz) /Optional110V Equipment power 1300W 1900W 2500W 5100W Size 300×400×435mm 350×400×445mm 455×410×455mm 560×600×625mm Weight 62Kg 98Kg 365Kg 425Kg Configuration instruction The control panel size can be customized to be wider according to customer requirements. The column height can also be increased. The thermostat can be optionally equipped with remote control function. This product can be customized or improved according to customer requirements.*

Operating Procedure

-

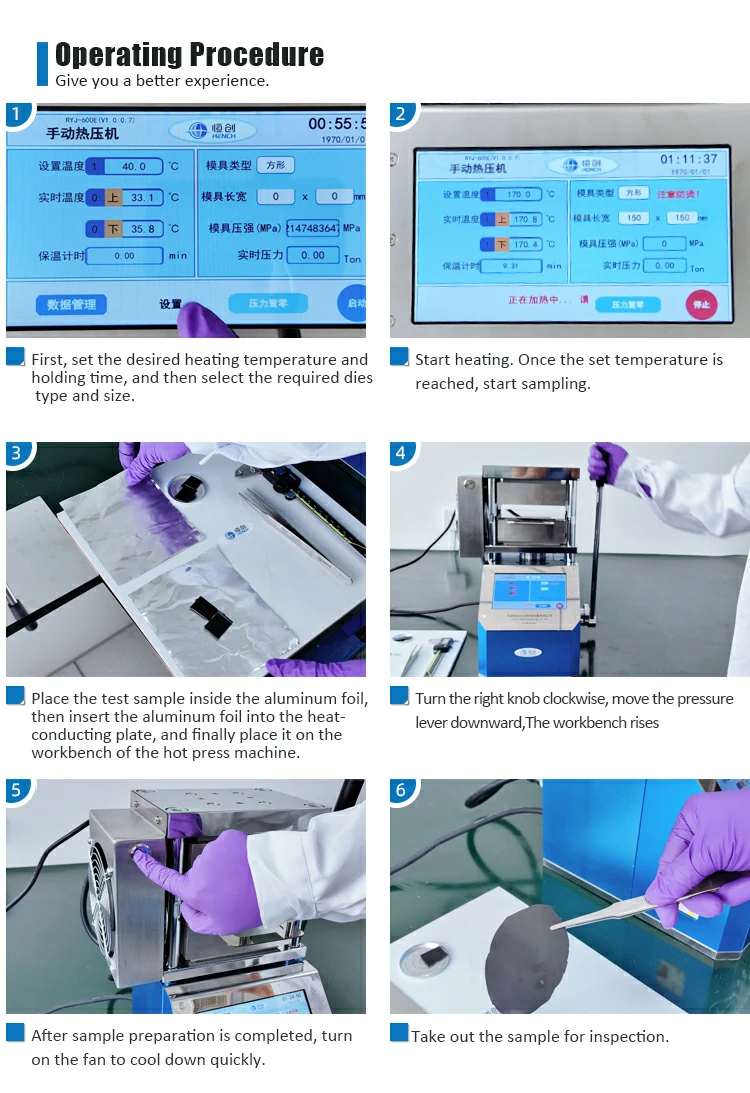

First, set the desired heating temperature and holding time, and then select the required die type and size.

-

Start heating. Once the set temperature is reached, begin sampling.

-

Place the test sample inside the aluminum foil, then insert the aluminum foil into the heat-conducting plate, and finally place it on the workbench of the hot press machine.

-

Turn the right knob clockwise to move the pressure lever downward, causing the workbench to rise.

-

After sample preparation is completed, turn on the fan for rapid cooling.

-

Take out the sample for inspection.

Why Choose Hench?

Hench Technology Co., Ltd., based in Tianjin, China, is a trusted manufacturer of precision laboratory and industrial presses. Hench designs high-quality heated hydraulic presses that deliver performance, safety, and ease of use. Their equipment serves universities, labs, and industrial clients worldwide, backed by professional support and rigorous quality control.

-

Manual Hot Press Hydraulic Machine Large Panel YPH-800D

Overview

The YPH‑800D is a robust hot press hydraulic machine designed for large panels and industrial-scale lab operations. It combines manual hydraulic control with advanced heating to provide precise, consistent pressure across broad surfaces.

Key Features of Manual Hot Press Hydraulic Machine

- Control pressure and temperature:0.1T/0.1°C(Customizable accuracy)

- Dwell time:Unlimited time (manual pressure relief)

- Display usage:7 inch LCD touch screen/English interface can be switched

- Die pressure conversion:PCB control program automatically converts to display sample pressure (Mpa)

- Heating plate type:Four-column positioning thermal insulation design, upper plate screw suspension design/electroplated polished panel

- Heating core material:Aluminum heating core

- Heat insulation method:Imported mica heat insulation board

- Security configuration:Mold temperature exceeds 50'C, temperature controller prompts "Pay attention to anti-hot"

- Temperature die:5 stages adjustable continuous temperature control - automatic heating - automatic insulation - natural cooling

Applications

Ideal for pressing large polymer, rubber, composite, or layered panels in laboratory or industrial environments. Its reliability and precision reflect the quality standards of professional hydraulic press machines.

Product Description

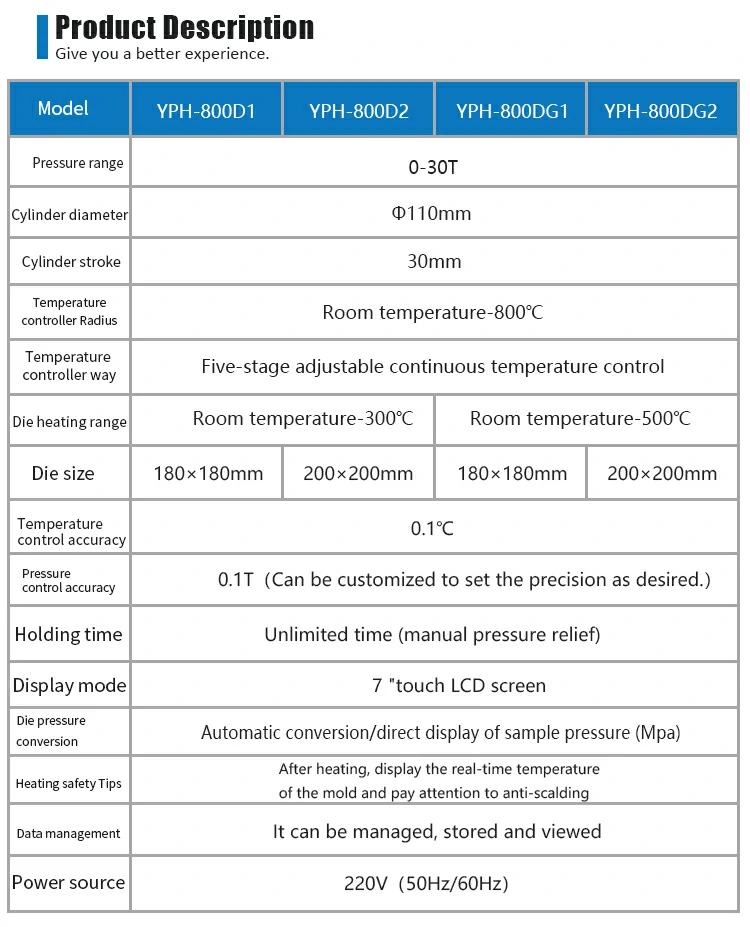

Model YPH-800D1 YPH-800D2 YPH-800DG1 YPH-800DG2 Pressure range 0-30T Cylinder diameter Φ110mm Cylinder stroke 30mm Temperature controller Radius Room temperature-800∘C Temperature controller way Five-stage adjustable continuous temperature control Die heating range Room temperature-300∘C Room temperature-500∘C Die size 180x180mm 200x200mm 180x180mm 200x200mm Temperature control accuracy 0.1∘C Pressure control accuracy 0.1T (Can be customized to set the precision as desired.) Holding time Unlimited time (manual pressure relief) Display mode 7 "touch LCD screen Die pressure conversion Automatic conversion/direct display of sample pressure (Mpa) Heating safety Tips After heating, display the real-time temperature of the mold and pay attention to anti-scalding Data management It can be managed, stored and viewed Power source 220V (50Hz/60Hz) Operating Procedure

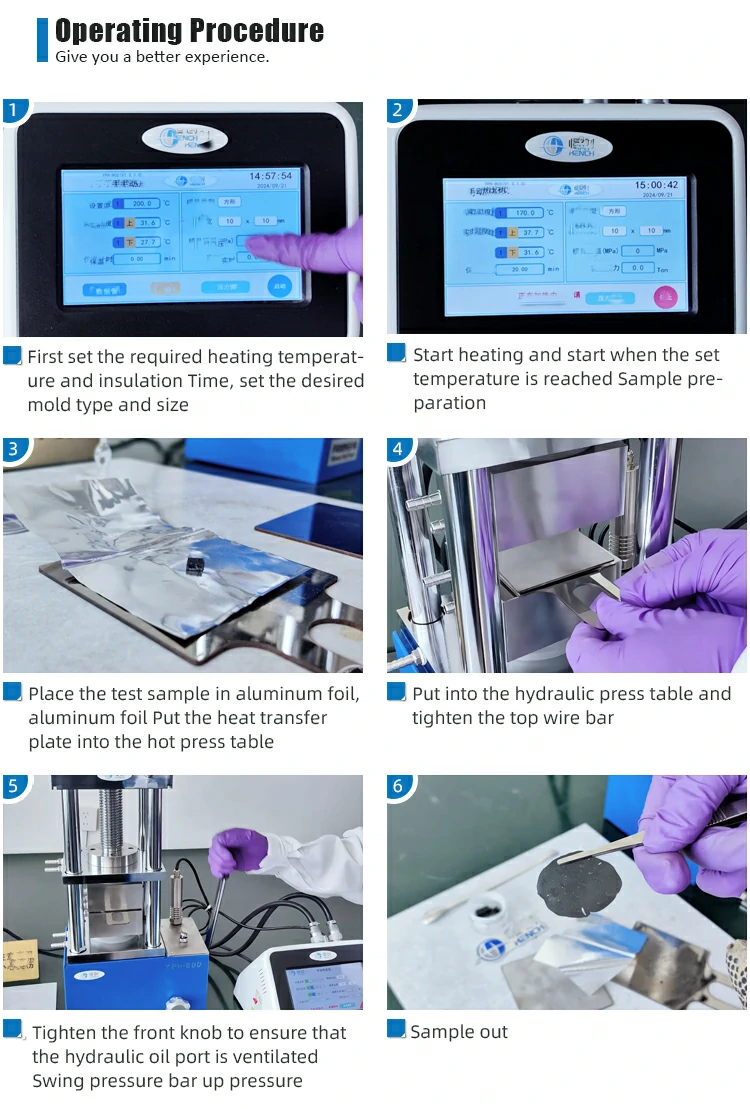

-

First, set the required heating temperature and insulation time, as well as the desired mold type and size.

-

Start heating, and begin sample preparation once the set temperature is reached.

-

Place the test sample in aluminum foil, then place the aluminum foil with the heat transfer plate onto the hot press table.

-

Insert it into the hydraulic press table and tighten the top screw bar.

-

Tighten the front knob to ensure the hydraulic oil port is ventilated, then swing the pressure bar upward to apply pressure.

-

Remove the prepared sample.

Why Hench?

Hench Technology Co., Ltd., based in Tianjin, China, is a leading hydraulic press manufacturer, producing high-quality hydraulic and heated presses for lab and industrial applications. Hench machines are designed for durability, safety, and ease of use, serving research institutes, universities, and industrial clients worldwide. Their expertise ensures consistent performance, professional support, and customizable solutions for complex pressing tasks.

High-Quality Laboratory Presses for Precise Sample Preparation

Hench Technology offers advanced laboratory presses that ensure accurate and reproducible results for a variety of laboratory applications. Designed for efficiency and reliability, these presses are ideal for powders, tablets, and other sample types.

Trusted Lab Equipment Supplier

As a professional lab equipment supplier, Hench Technology provides comprehensive solutions and technical support for laboratory operations. Our commitment to innovation and quality ensures that every laboratory press meets the highest standards.