Lab Hydraulic Presses

Laboratory press is a precision hydraulic press machine designed specifically for scientific research, analytical sample preparation, and material testing. Unlike industrial hydraulic presses, which prioritize maximum force, lab hydraulic presses focus on controlled pressure, repeatability, safety, and compliance with industry standards.

Hench offers a comprehensive portfolio of laboratory hydraulic presses to meet diverse laboratory and light industrial requirements, covering applications from routine sample preparation to advanced material research.

| Press Type | Key Features | Typical Applications |

|---|---|---|

| Manual & Digital Presses | Compact bench-top design, manual or digital pressure control, precise force adjustment | Low-throughput laboratories, educational use, small-sample and analytical pellet preparation |

| Automatic Presses | Fully programmable operation, high repeatability, automated pressing cycles | High-throughput research labs, quality control environments, standardized sample preparation |

| Heated Presses | Integrated temperature control, stable heating system, pressure–temperature synchronization | Polymers, composites, thermoplastic materials, advanced material processing |

| Vacuum Presses | Vacuum-assisted pressing, minimized air entrapment, improved density uniformity | Sensitive powders, analytical samples, materials prone to oxidation or porosity |

| Isostatic Presses | Multi-directional uniform pressure, liquid pressure transmission principle | Ceramics, pharmaceuticals, powder metallurgy, specialized material research |

This full lineup ensures laboratories can find the right laboratory press or lab hydraulic press machine for FTIR, XRF, or general sample preparation, delivering precision, repeatability, and compliance with ASTM and ISO standards.

Contact us to get the latest lab hydraulic press machine prices.

-

Vacuum Box Automatic Laboratory Hot Press VHP

Model:VHP-200D/300E

Pressure range:0-20T/0-30T

Hot press plate size:200×200mm/300×300mm

Heating range:Room temperature -3009C/0.1°C

Pressure die:Automatic pressure/slow pressure

Number of pressurized stages:5 Arbitrary Settings

Vacuum degree:-0.95Mpa

Heating core material:Aluminum heating core

Heat insulation method:Imported mica heat insulation board

Equipment power:2200W/2800W

Size:400x520x790mm/650x750x790mm

Weight:235kg/420Kg

-

Fully Automatic Heating Laboratory Tablet Press HZT-800E/F/G

Model:HZT-800E/F/G

Pressure range:0-30T/40T

Piston diameter:110mm/130mm

Cytinder stroke:55mm

Temperature control:Room temperature -600°C

Heatingrange:300℃/500℃

Die size:300x300mm/400x400mm/600x600mm

Effective space:300x65mm/400x65mm/600x65mm

Equipment power:3000W/5500W/12.5KW

Size:400x500x750mm/500x600x785mm/700x800x1110mm

Weight:350Kg/450Kg/450Kg

-

Fully Automatic Laboratory Heat Press HZT-800D/DG

Model:HZT-800D/DG

Pressure range:0-25T

Piston diameter:95mm

Cylinder stroke:60mm

Temperature control:Room temperature -600°C

Heating range:300℃/500℃

Die size:180×180mm/200×200mm

Effective space:180x65mm/200x65mm

Input Power:220V(50Hz/60Hz)/110v is available

Equipment power:2200W

Size:280x420x625mm

Weight:163Kg

-

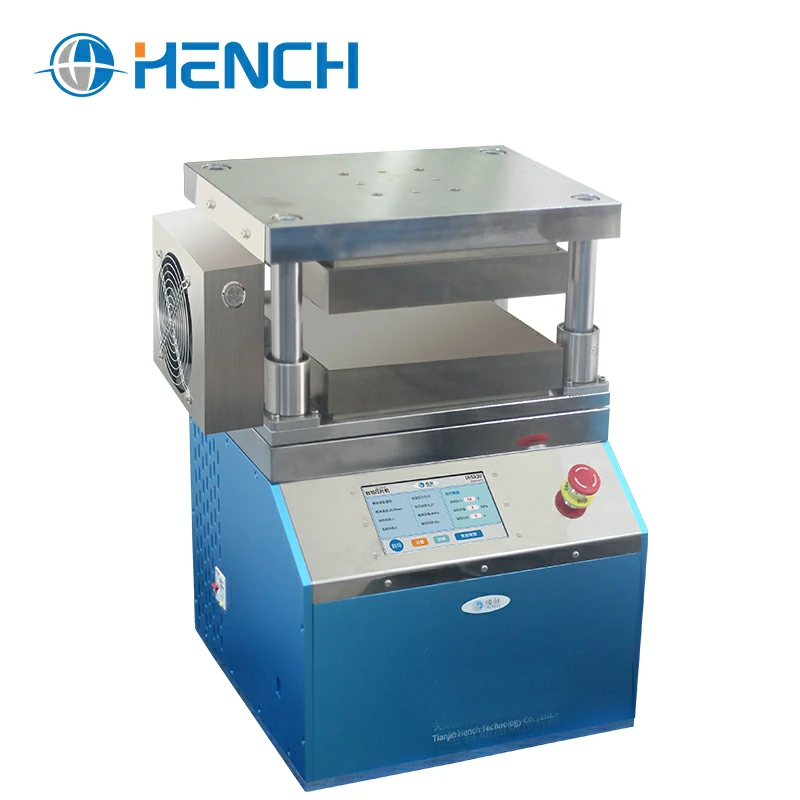

Manual Integrated Hot Hydraulic Press HPC-800E/F

Model:HPC-800E/F

Pressure range:0-24T/30

Piston diameter:95mm/110mm

Cylinder stroke:60mm

Temperature range:Room temperature-800°C

Die size:300x300mm/400×400mm

Effective space:150x60mm

Equipment power:2500W/5100W

Size:455x410x455mm/560x600x625mm

Weight:365Kg/425Kg

-

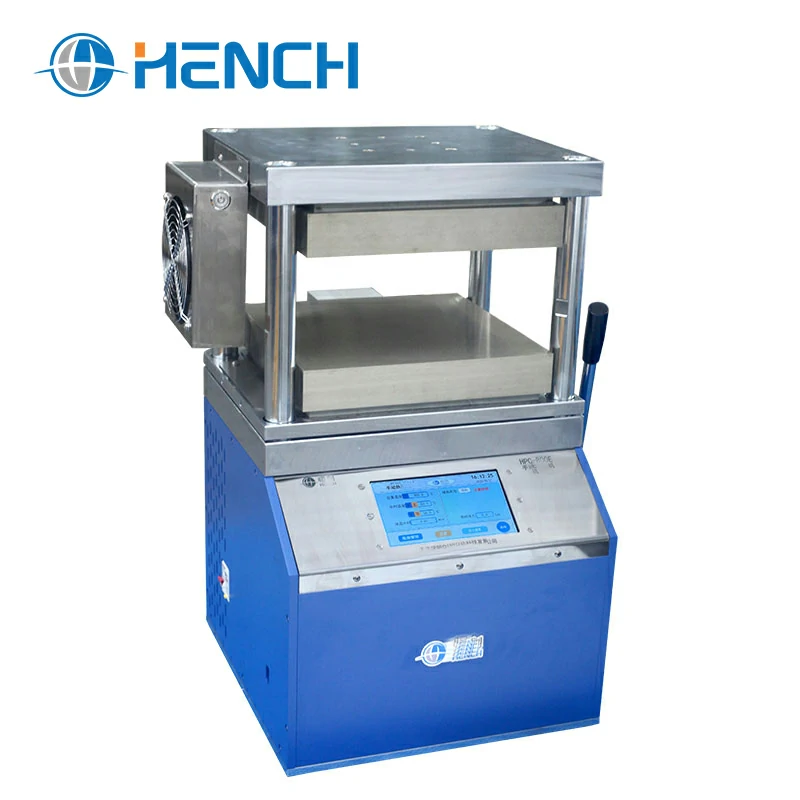

Manual Integrated Heating Tablet Press Machine HPC-800D/DG

Model:HPC-800D/DG

Pressure range:0-10T

Piston diameter:65mm

Cylinder stroke:60mm

Temperature range:Room temperature-800°C

Die size:150x150mm

Effective space:150x60mm

Equipment power:1300W

Size:300x400x435mm

Weight:62Kg

-

Manual Hot Press Hydraulic Machine Large Panel YPH-800D

Modle:YPH-800D

Pressure limit:0-30T

Piston diameter:110mm

Cylinder stroke:50mm

Temperature range:Room temperature -800°C

Heating range:300°C

Die size:200x200mm

Effective space:200x140mm

Input Power:220V(50Hz/60Hz)/0ptional 110V

Equipment power:1900W

Main engine size:450x260x725mm

Thermostat size:230x270x180mm

Weight:183Kg

Lab Hydraulic Presses for Scientific Sample Preparation

Hench offers a complete range of laboratory hydraulic presses designed for FTIR, XRF, material testing, pharmaceutical research, and industrial sample preparation. Our presses combine precision, repeatability, and safety with compliance to international laboratory standards (ASTM / ISO), making them reliable solutions for both research and quality control laboratories.

Whether you need manual, digital, automatic, heated, or vacuum lab hydraulic presses, Hench provides machines suitable for various sample types and analytical workflows.

Laboratory Press Applications

Hench lab hydraulic presses are widely used in:

-

FTIR sample preparation (KBr pellets, transparent discs)

-

XRF pellet pressing for elemental analysis

-

Powder compaction for material characterization

-

Research and development of ceramics, catalysts, and composites

-

Pharmaceutical and chemical laboratory testing

Each laboratory pellet press ensures uniform pressure distribution, yielding consistent and reliable analytical results.

Laboratory Hydraulic Press Selection Guide

To help laboratories quickly identify the most suitable laboratory press for their application, Hench provides the following selection guide based on operation type and pressure capacity. This decision matrix simplifies comparison and ensures optimal performance for FTIR, XRF, and advanced material research.

1. Selection by Operation Type

Hench provides multiple types of lab hydraulic presses, each designed for specific laboratory applications:

Manual Laboratory Press

Hand-operated pumps generate pressure for routine sample preparation. Ideal for educational labs and low-throughput environments.

-

Compact bench-top design

-

Adjustable pressure up to 30–40 tons

-

Manual or digital display for accurate monitoring

-

Suitable for FTIR and XRF pellet preparation

Automatic Hydraulic Press Machine

Electrically powered, programmable presses with automated pressure ramps, dwell times, and release cycles. Suitable for high-throughput laboratories requiring repeatable results and minimal manual intervention.

-

Pressure range: 10–60 tons

-

Fully programmable cycles

-

Optional heating for polymer/composite testing

-

Compatible with multiple die sizes and materials

Vacuum Hydraulic Press

Applies pressure under reduced air conditions to minimize trapped air and improve pellet density, especially for sensitive or low-porosity materials.

-

Vacuum-assisted pressing

-

Optional heating and digital pressure control

-

Compatible with FTIR and XRF dies

-

Ensures uniform, high-quality sample preparation

Heated Laboratory Press

Combines controlled pressure with temperature regulation for polymers, composites, and advanced materials research.

-

Temperature control up to 300°C

-

Accurate pressure control with PLC/PID system

-

Safety interlocks for laboratory compliance

-

Optional data acquisition for reproducible results

Isostatic Pressing Machines

Used for specialized research and advanced material compaction, providing uniform pressure distribution in multiple directions. Suitable for ceramic, pharmaceutical, and materials research applications.

-

Manual and automatic models available

-

High-pressure uniformity

-

Optional heated or vacuum configurations

-

Supports experimental reproducibility

2. Selection by Pressure Capacity

Choosing the correct tonnage is critical for achieving proper sample density and analytical accuracy.

-

15 Ton Hydraulic Press

Recommended for FTIR KBr pellets, routine powder compaction, and small-diameter dies. -

24 Ton Hydraulic Press

Suitable for higher-density pellets, larger die sizes, and multi-purpose laboratory applications. -

40–60 Ton Hydraulic Press

Ideal for XRF sample preparation, battery materials, ceramics, and advanced materials research requiring higher compaction forces and superior uniformity.

Technical Specifications and Standards Compliance:

| Press Type | Pressure Range | Control Mode | Temperature Control | Industry Standard | Typical Applications |

|---|---|---|---|---|---|

| Manual Laboratory Press | 5–30 Ton | Manual pump | Ambient | ASTM / ISO compatible | FTIR sample prep, educational labs |

| Digital Laboratory Press | 5–40 Ton | Digital gauge | Ambient | ASTM / ISO compatible | FTIR & XRF pellet pressing |

| Automatic Hydraulic Press Machine | 10–60 Ton | Programmable | Optional heating | ASTM / ISO compliant | High-throughput analytical labs |

| Vacuum Laboratory Press | 10–40 Ton | Vacuum assisted | Optional heating | ASTM / ISO compliant | High-density pellets, sensitive powders |

| Heated Laboratory Press | 10–50 Ton | Pressure + temperature | Up to 300°C | ASTM / ISO compliant | Polymers, composites, advanced materials |

Contact us to get the latest lab hydraulic press machine prices.

Hench Advantages

Hench lab hydraulic presses integrate state-of-the-art control systems for precision and safety:

-

PLC & PID Control for precise pressure and temperature management

-

Digital touch-screen interface for monitoring and programmable cycles

-

Automated pressure ramping and release for repeatable pellet quality

-

Safety interlocks and emergency stop for operator protection

-

Optional data acquisition and recording for analytical documentation

These features ensure laboratory staff can maintain consistent sample quality while complying with safety regulations.

About Hench

Hench is a leading lab pressing machine manufacturer with over 20 years of experience. Our products are trusted worldwide in research institutions, universities, and industrial laboratories. We focus on precision, reliability, safety, and compliance, ensuring every laboratory press meets rigorous scientific requirements.

Our Advantages:

-

High-precision hydraulic press machines for consistent sample preparation

-

Multiple series covering manual, digital, automatic, vacuum, and heated applications

-

Fully compatible with FTIR and XRF pellet dies

-

Designed to comply with ASTM and ISO laboratory standards

-

Robust design ensures long-term stability and reliable performance

-

Dedicated technical support and after-sales service for laboratory clients

Trusted by Research and Industrial Labs

Hench lab hydraulic presses have been adopted by leading laboratories for FTIR, XRF, and material research, demonstrating our commitment to quality, compliance, and laboratory success.

Frequently Asked Questions

Q1: What is the difference between a laboratory press and an industrial hydraulic press?

Laboratory press is designed for precise, controlled pressure applications in small-scale sample preparation, focusing on repeatability, safety, and compliance with ASTM/ISO standards. An industrial press prioritizes high force for large-scale manufacturing but often lacks fine control suitable for lab samples.

Q2: Which Hench lab hydraulic press is suitable for FTIR or XRF sample preparation?

Hench digital, automatic, and vacuum laboratory presses are ideal for FTIR and XRF pellet preparation. These presses provide uniform pressure distribution, precise control, and compatibility with standard pellet dies. Heated or vacuum options may be selected based on sample material sensitivity.

Q3: Do Hench lab hydraulic presses comply with industry standards?

Yes. All Hench presses are designed to meet ASTM and ISO standards for laboratory sample preparation, including temperature uniformity, platen parallelism, and pressure accuracy. Compliance ensures reliable analytical results and laboratory safety.

Q4: Are Hench presses equipped with safety and automation features?

Absolutely. Our presses include:

-

PLC & PID control for precise pressure and temperature management

-

Digital touch-screen interface for programmable cycles

-

Automated pressure ramping and release

-

Emergency stop and safety interlocks

-

Optional data acquisition for record-keeping

Q5: Can Hench lab hydraulic presses be used for polymers, composites, or sensitive powders?

Yes. Heated presses are ideal for polymers and composites, while vacuum presses minimize air entrapment for sensitive powders. Hench offers multiple configurations to meet diverse lab applications.

Q6: How do I maintain and calibrate a Hench laboratory press?

Routine maintenance includes:

-

Checking hydraulic fluid levels and replacing if necessary

-

Inspecting seals, valves, and piston for leaks or wear

-

Cleaning platen surfaces before and after use

-

Calibrating pressure gauges and digital controls periodically

Hench provides detailed manuals and technical support to ensure long-term performance.

.png)

.png)