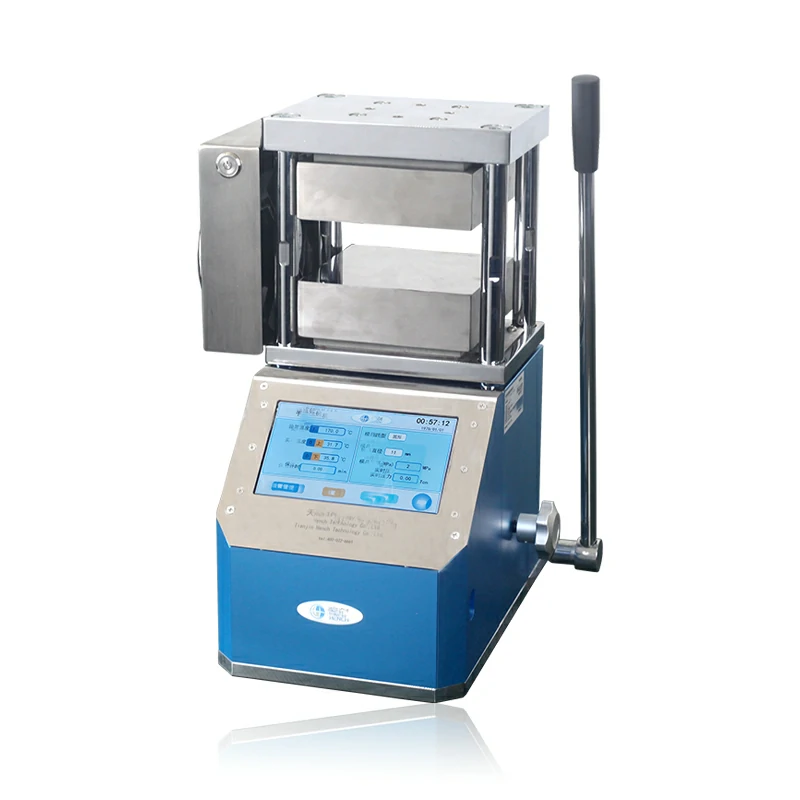

Manual Integrated Heating Tablet Press Machine HPC-800D/DG

Manual Integrated Heating Tablet Press Machine

The HPC‑800D/DG is a precise, compact tablet press machine designed for laboratory and small-scale production, combining manual control with reliable heating and pressing.

- Temperature control:5 stages adjustable continuous temperature control - automatic heating - automatic insulation - natural cooling

- Heating range:300°C(D1、D2、E、F)/500°(DG1、DG2、EG、FG)

- Dwell time:Unlimited time (manual pressure relief)

- Display usage:7 inch LCD touch screen/English interface can be switched

- Die pressure conversion:PCB control program automatically converts to display sample pressure (Mpa)

- Heating plate type:Four-column posiltioning thermal insulation design, upper plate screw suspension desien/electroplated polished banel

- Heating core material:300'CAluminum heatingcore (D1、D2、E、F)/500"c Copper heatingcore (DG1、DG2、EG、FG)

- Heat insulation method:Imported mica heat insulation board

- Cooling method:Standard wall hanging air cooler

- Passive safety:With leakage protection + emergency stop switch

- Security confguration:Optional 110V die temperature over 50℃, thermostat automatically prompts "pay attention to anti-hot"

- Input Power:220V(50Hz/60Hz)/110V is available

- Explain:The control panel size can be customized to increase the width and the column height.

Design & Control Advantages

-

Integrated heating and hydraulic pressing provide even pressure distribution and accurate temperature control.

-

Simple control interface allows lab technicians to set pressure and temperature precisely, reflecting the high standards of advanced hydraulic press machines.

-

Safety features include mechanical fault alarms, emergency stop, and over-temperature protection, ensuring secure and reliable operation.

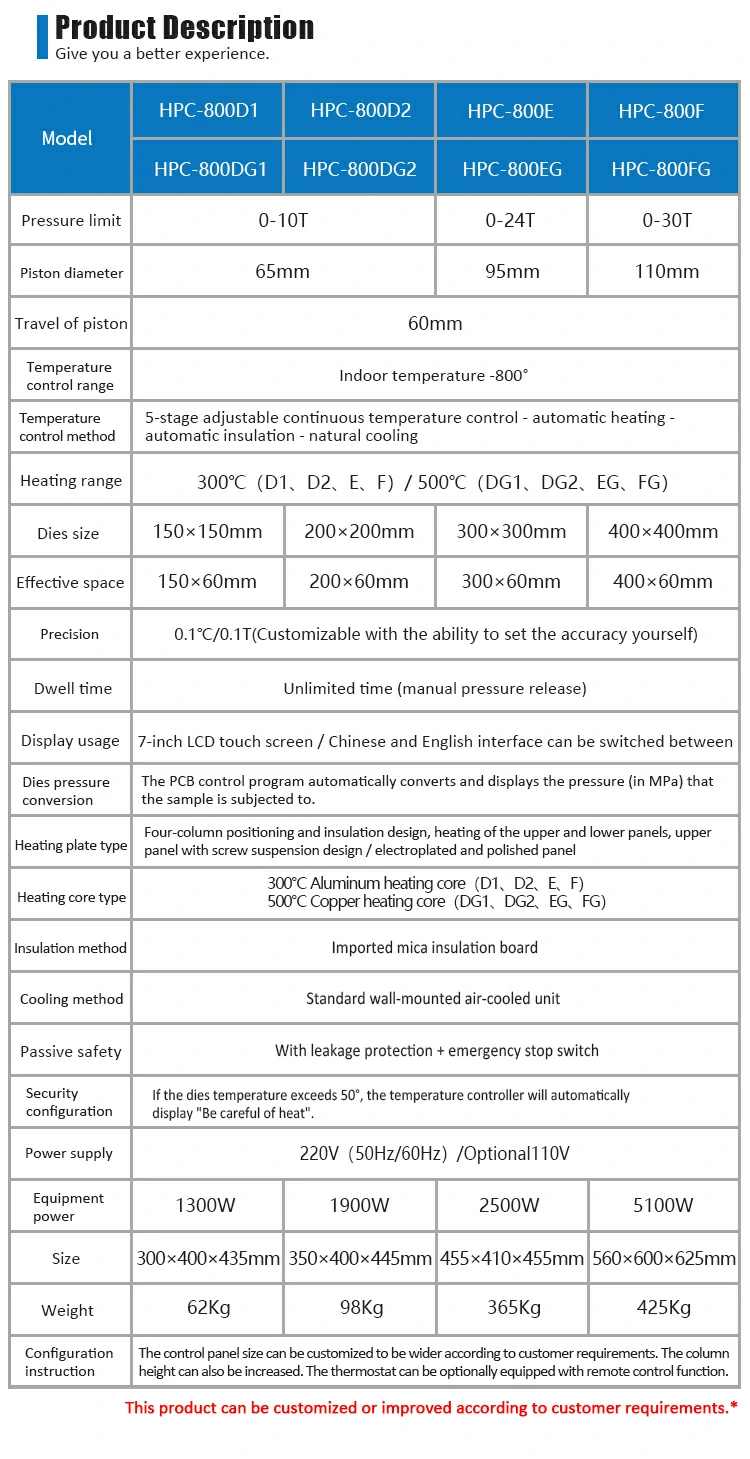

Product Description

| Model | HPC-800D1 | HPC-800D2 | HPC-800E | HPC-800F |

| HPC-800DG1 | HPC-800DG2 | HPC-800EG | HPC-800FG | |

| Pressure limit | 0-10T | 0-24T | 0-30T | |

| Piston diameter | 65mm | 95mm | 110mm | |

| Travel of piston | 60mm | |||

| Temperature control range | Indoor temperature -800° | |||

| Temperature control method | 5-stage adjustable continuous temperature control - automatic heating - automatic insulation - natural cooling | |||

| Heating range | 300°C (D1, D2, E, F) / 500°C (DG1, DG2, EG, FG) | |||

| Dies size | 150×150mm | 200×200mm | 300×300mm | 400×400mm |

| Effective space | 150×60mm | 200×60mm | 300×60mm | 400×60mm |

| Precision | 0.1°C/0.1T(Customizable with the ability to set the accuracy yourself) | |||

| Dwell time | Unlimited time (manual pressure release) | |||

| Display usage | 7-inch LCD touch screen / Chinese and English interface can be switched between | |||

| Dies pressure conversion | The PCB control program automatically converts and displays the pressure (in MPa) that the sample is subjected to. | |||

| Heating plate type | Four-column positioning and insulation design, heating of the upper and lower panels, upper panel with screw suspension design / electroplated and polished panel | |||

| Heating core type | 300°C Aluminum heating core (D1, D2, E, F) 500°C Copper heating core (DG1, DG2, EG, FG) | |||

| Insulation method | Imported mica insulation board | |||

| Cooling method | Standard wall-mounted air-cooled unit | |||

| Passive safety | With leakage protection + emergency stop switch | |||

| Security configuration | If the dies temperature exceeds 50°, the temperature controller will automatically display "Be careful of heat". | |||

| Power supply | 220V (50Hz/60Hz) /Optional110V | |||

| Equipment power | 1300W | 1900W | 2500W | 5100W |

| Size | 300×400×435mm | 350×400×445mm | 455×410×455mm | 560×600×625mm |

| Weight | 62Kg | 98Kg | 365Kg | 425Kg |

| Configuration instruction | The control panel size can be customized to be wider according to customer requirements. The column height can also be increased. The thermostat can be optionally equipped with remote control function. | |||

This product can be customized or improved according to customer requirements.*

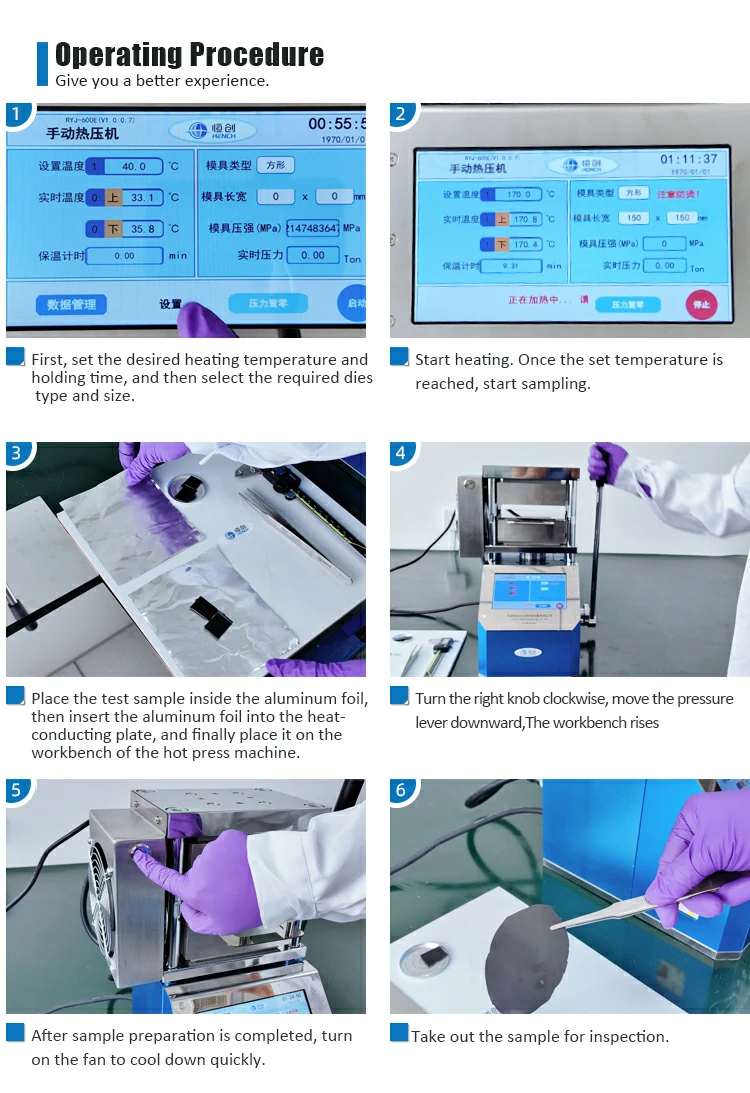

Operating Procedure

-

First, set the desired heating temperature and holding time, and then select the required die type and size.

-

Start heating. Once the set temperature is reached, begin sampling.

-

Place the test sample inside the aluminum foil, then insert the aluminum foil into the heat-conducting plate, and finally place it on the workbench of the hot press machine.

-

Turn the right knob clockwise to move the pressure lever downward, causing the workbench to rise.

-

After sample preparation is completed, turn on the fan for rapid cooling.

-

Take out the sample for inspection.

Why Choose Hench?

Hench Technology Co., Ltd., based in Tianjin, China, is a trusted manufacturer of precision laboratory and industrial presses. Hench designs high-quality heated hydraulic presses that deliver performance, safety, and ease of use. Their equipment serves universities, labs, and industrial clients worldwide, backed by professional support and rigorous quality control.