laboratory presses

Discover Hench Technology’s range of precision laboratory presses, designed for efficient sample preparation and reliable performance. For inquiries or quotes, contact us today.

-

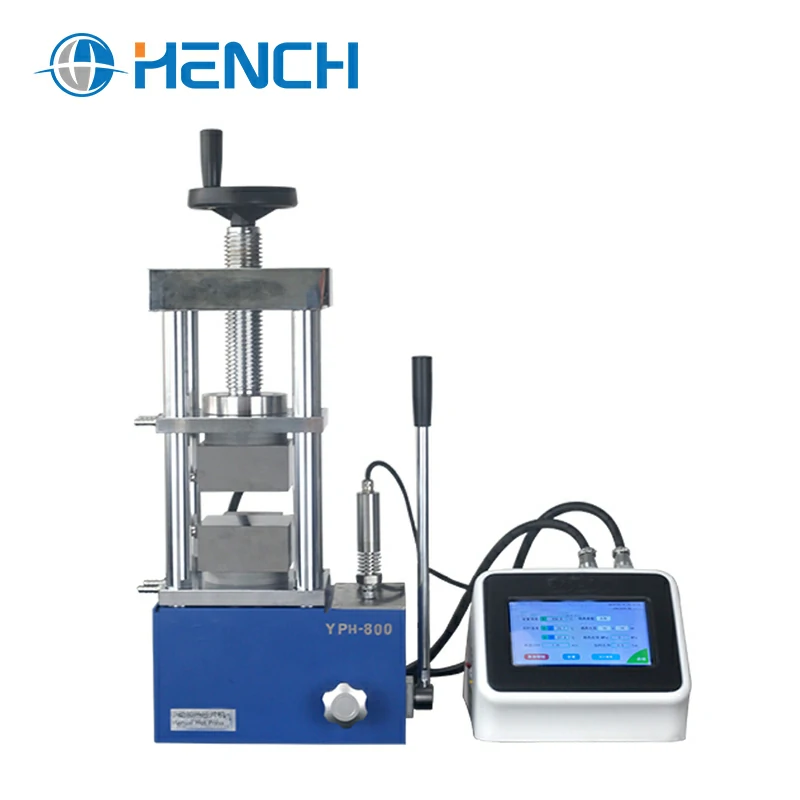

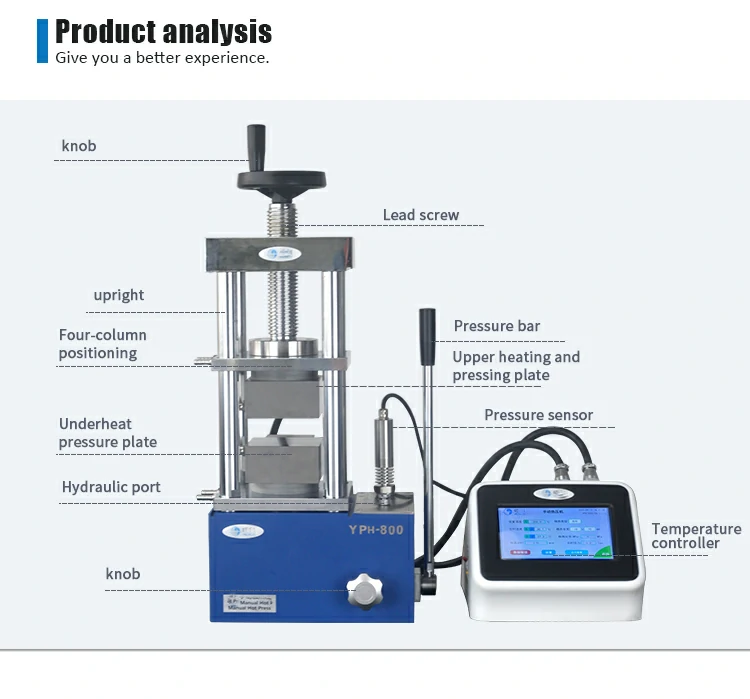

Hot Tablet Press Handheld YPH-800C

Overview

YPH series hot press adopts split structure, manual hydraulic drive, lead screw suspension heating plate, with fast pressure, easy to operate Easy maintenance and other advantages. Multi-stage temperature control can meet the needs of various powders, plastic films, rubber materials and solid materials for high temperature and high pressing samples.

Key Features

-

Integrated heating system ensures uniform temperature control, making it an effective heated hydraulic press for powders, polymers, and small sample materials.

-

Manual operation with smooth hydraulic pressing provides consistent results, reflecting the high standard expected of advanced hydraulic press machines.

-

Lightweight and portable, yet durable, featuring polished die surfaces and built-in thermal insulation to ensure safe and efficient lab work.

-

Low power consumption and easy maintenance make it a practical choice for frequent use in research or small-scale production environments.

Applications

Perfect for pressing small tablets or pellets in laboratories, R&D centers, or educational facilities. Often used alongside other lab supplies for sample preparation and analysis, this handheld press ensures precision and repeatability.

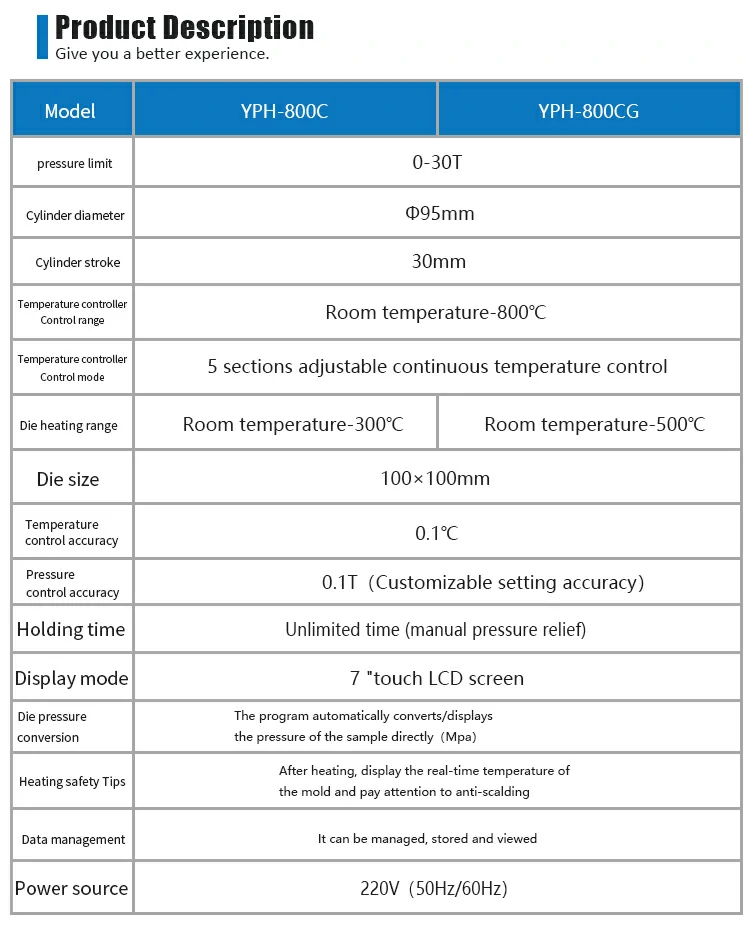

Product Description

Model YPH-800C YPH-800CG pressure limit 0-30T Cylinder diameter Φ95mm Cylinder stroke 30mm Temperature controller Control range Room temperature-800∘C Temperature controller Control mode 5 sections adjustable continuous temperature control Die heating range Room temperature-300∘C Room temperature-500∘C Die size 100x100mm Temperature control accuracy 0.1∘C Pressure control accuracy 0.1T (Customizable setting accuracy) Holding time Unlimited time (manual pressure relief) Display mode 7 "touch LCD screen Die pressure conversion The program automatically converts/displays the pressure of the sample directly (Mpa) Heating safety Tips After heating, display the real-time temperature of the mold and pay attention to anti-scalding Data management It can be managed, stored and viewed Power source 220V (50Hz/60Hz) Operating Procedure

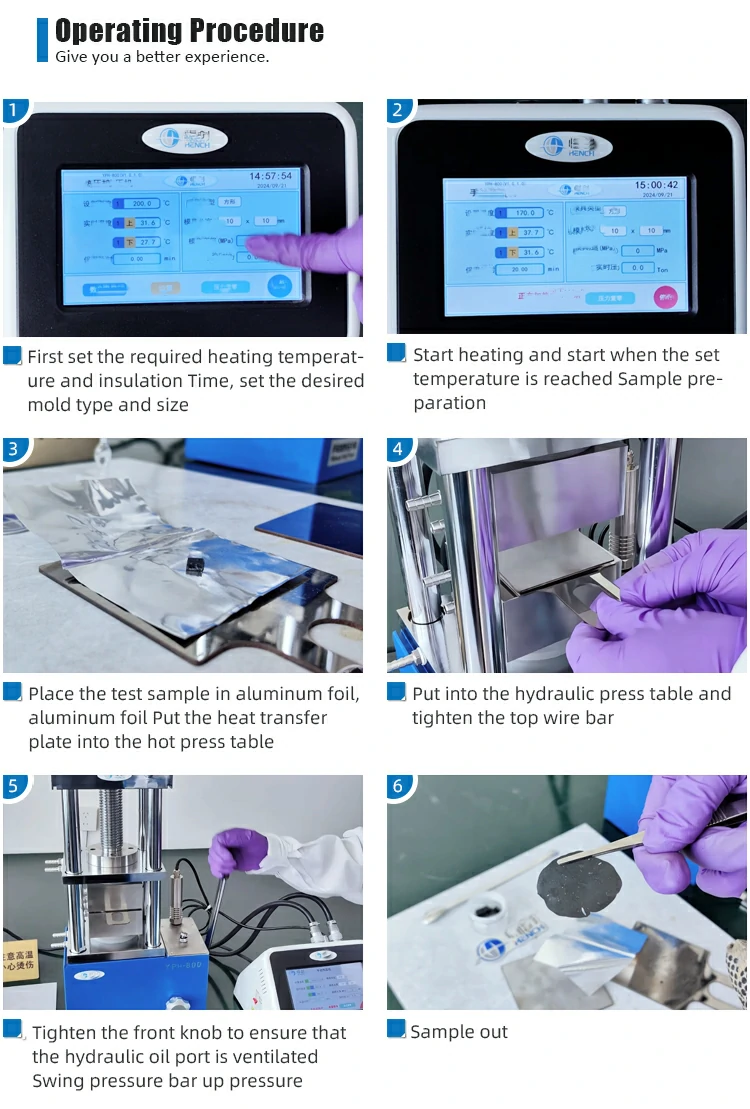

-

First, set the required heating temperature and insulation time, as well as the desired mold type and size.

-

Start heating, and begin sample preparation once the set temperature is reached.

-

Place the test sample in aluminum foil, then place the aluminum foil with the heat transfer plate onto the hot press table.

-

Insert it into the hydraulic press table and tighten the top screw bar.

-

Tighten the front knob to ensure the hydraulic oil port is ventilated, then swing the pressure bar upward to apply pressure.

-

Remove the prepared sample.

Why Hench?

Hench Technology Co., Ltd., headquartered in Tianjin, China, is a trusted hydraulic press manufacturer specializing in laboratory and industrial presses. Hench provides reliable hydraulic press machines designed for safety, performance, and ease of use. Their solutions support universities, laboratories, and industrial clients globally, backed by professional service and quality assurance.

-

-

20/30/40/60/100-ton Fully Automatic Isostatic Desktop Tablet Press Machine HAP-J

Isostatic Desktop Tablet Press Machine Product Features

HAP-J series automatic isostatic press adopts upper plate rocker arm knot structure, more convenient operation,automatic program operation: program pressures low pressure -pressure retention -pressure replenishment - periodic pressure relief, etc.

Key Features

-

Available in 20T, 30T, 40T, 60T, and 100T models, with programmable pressing cycles for maximum reproducibility.

-

Compact desktop design allows easy integration into labs while maintaining high stability and precision.

-

Advanced control system with LCD interface for setting pressure, dwell time, and pressing sequence.

-

The robust hydraulic mechanism ensures consistent pressure, reflecting the quality of professional hydraulic press machines.

-

Suitable for frequent lab use, easy maintenance, and efficient operation, making it a valuable addition to any lab supplies inventory.

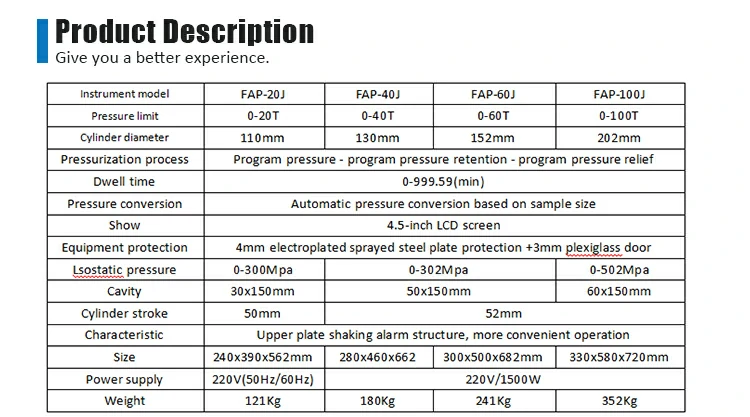

Product Description

Instrument model FAP-20J FAP-40J FAP-60J FAP-100J Pressure limit 0-20T 0-40T 0-60T 0-100T Cylinder diameter 110mm 130mm 152mm 202mm Pressurization process Program pressure - program pressure retention - program pressure relief Dwell time 0-999.59(min) Pressure conversion Automatic pressure conversion based on sample size Show 4.5-inch LCD screen Equipment protection 4mm electroplated sprayed steel plate protection +3mm plexiglass door Lsostatic pressure 0-300Mpa 0-302Mpa 0-502Mpa Cavity 30x150mm 50x150mm 60x150mm Cylinder stroke 50mm 52mm Characteristic Upper plate shaking alarm structure, more convenient operation Size 240x390x562mm 280x460x662mm 300x500x682mm 330x580x720mm Power supply 220V(50Hz/60Hz) 220V/1500W Weight 121Kg 180Kg 241Kg 352Kg Why Hench?

Hench Technology Co., Ltd., based in Tianjin, China, specializes in laboratory and industrial press solutions. Hench offers a full range of high-quality hydraulic press machines designed for durability, safety, and precision. Their desktop and industrial tablet presses integrate seamlessly for research and production, providing professional support and proven quality worldwide.

-

-

20/40/60-ton Isostatic Electric Press Machine HDP-J

Isostatic Electric Press Machine Overview

The HDP‑J series is a desktop-to-pilot scale electric press machine designed to deliver uniform isostatic pressing for powders, polymers, and composite materials. Its precise electric pressing mechanism ensures consistent sample quality every cycle.

Technical Advantages

-

Available in 20T, 40T, and 60T configurations, the press allows fully programmable pressing cycles for reproducible results.

-

Advanced control system offers adjustable pressure, dwell time, and pressing sequence, a hallmark of high-performance hydraulic press machines.

-

Compact yet sturdy design integrates easily into laboratory settings while supporting reliable industrial-level operation.

Practical Applications

Perfect for laboratories, R&D centers, and pilot production, the HDP‑J is suitable for pressing tablets, pellets, and composite materials. Its precision makes it an essential piece of lab supplies for research and experimental workflows.

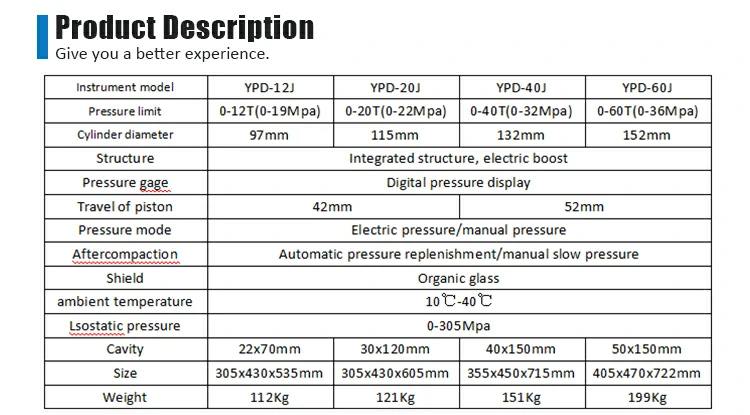

Product Description

Instrument model YPD-12J YPD-20J YPD-40J YPD-60J Pressure limit 0-12T(0-19MPa) 0-20T(0-22Mpa) 0-40T(0-32Mpa) 0-60T(0-36Mpa) Cylinder diameter 97mm 115mm 132mm 152mm Structure Integrated structure,electric boost Pressure gage Digital pressure display Travel of piston 42mm 52mm Pressure mode Electric pressure/manual pressure Aftercompaction Automatic pressure replenishment/manual slow pressure Shield Organic glass ambient temperature 10∘C−40∘C Isostatic pressure 0-305Mpa Cavity 22x70mm 30x120mm 40x150mm 50x150mm Size 305x430x535mm 305x430x605mm 355x450x715mm 405x470x722mm Weight 112Kg 121Kg 151Kg 199Kg Hench Advantage

Hench Technology Co., Ltd., based in Tianjin, China, is a leading hydraulic press supplier with decades of experience in laboratory and industrial press solutions. Hench provides durable, safe, and efficient presses that integrate seamlessly into laboratory and production workflows, supported by professional service and global quality standards.

-

-

12/20/40/60-ton Manual Hot Isostatic Pressing Machine YP-J/S

Manual Hot Isostatic Pressing Machine Overview

The YP‑J/S series is a high-precision Hot Isostatic Pressing Machine designed for laboratories and small-scale production. The powder can be formed directly by the isostatic pres-sure chamber,or the molded sample is pressed twice to make the sample density more uniform and removed the isostatic pressure chamber can also be used as an ordinary hydraulic press.

Key Features

-

Models available in 12T, 20T, 40T, and 60T, with piston diameter 110 mm and max travel 30 mm.

-

High-strength 3 chrome 13# die steel construction with side-opening protective plexiglass door for safety.

-

Compact design (305×195×605 mm, 105 kg) ensures easy integration into lab setups while maintaining reliable operation.

-

Precision pressure control reflects the quality of professional hydraulic press machines.

Applications

Ideal for pressing powders, polymers, and composite samples for laboratories, R&D, and pilot-scale production. Works seamlessly with other lab supplies to ensure reproducible results and consistent sample quality.

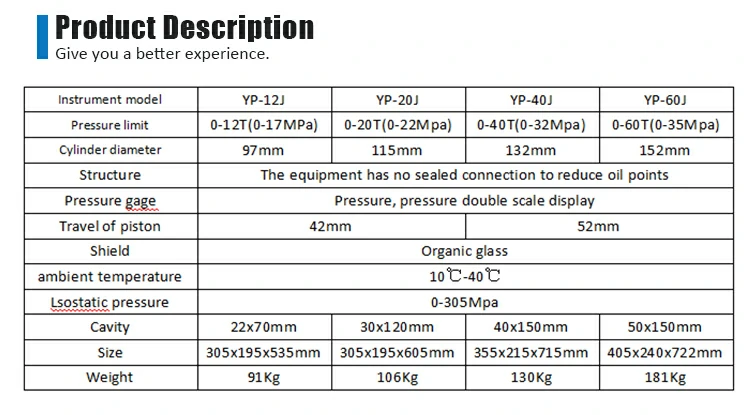

Product Description

Instrument model YP-12J YP-20J YP-40J YP-60J Pressure limit 0-1.2T(0-17MPa) 0-20T(0-22Mpa) 0-40T(0-32Mpa) 0-60T(0-35Mpa) Cylinder diameter 97mm 115mm 132mm 152mm Structure The equipment has no sealed connection to reduce oil points Pressure gage Pressure, pressure double scale display Travel of piston 42mm 52mm Shield Organic glass ambient temperature 10∘C−40∘C Lsostatic pressure 0-305Mpa Cavity 22x70mm 30x120mm 40x150mm 50x150mm Size 305x195x535mm 305x195x605mm 355x215x715mm 405x240x722mm Weight 91Kg 106Kg 130Kg 181Kg Pressure Conversion

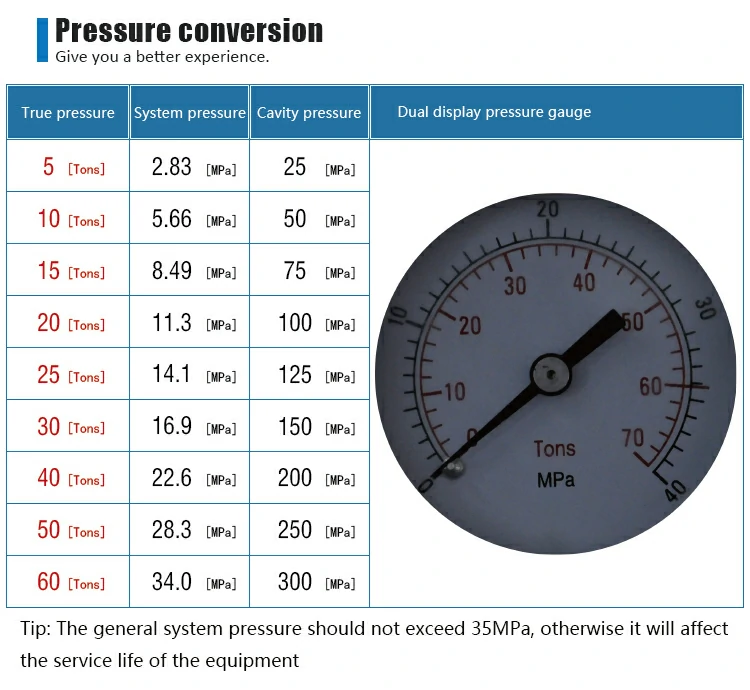

True Pressure System Pressure Cavity Pressure 5 [Tons] 2.83 [MPa] 25 [MPa] 10 [Tons] 5.66 [MPa] 50 [MPa] 15 [Tons] 8.49 [MPa] 75 [MPa] 20 [Tons] 11.3 [MPa] 100 [MPa] 25 [Tons] 14.1 [MPa] 125 [MPa] 30 [Tons] 16.9 [MPa] 150 [MPa] 40 [Tons] 22.6 [MPa] 200 [MPa] 50 [Tons] 28.3 [MPa] 250 [MPa] 60 [Tons] 34 [MPa] 300 [MPa] Tip: The general system pressure should not exceed 35MPa, otherwise it will affect the service life of the equipment.

Hench Technology Advantage

Hench Technology Co., Ltd., based in Tianjin, China, is a trusted hydraulic press supplier with decades of experience in designing reliable presses. Hench produces durable, precise, and safe equipment, including the YP‑J/S series, meeting the high standards of modern laboratories and industrial research.

-

-

30/40/60-ton Automatic Fluorescent Tablet Hyd Press Machine FTP-X

Automatic Fluorescent Tablet Hyd Press Machine Overview

The FTP-X series is a fully automatic Hyd Press Machine engineered for precise tablet preparation in X-ray fluorescence (XRF) analysis. Its automated pressing and demolding ensure uniform, high-quality pellets, making it ideal for laboratories requiring reproducible results.

Advanced Features

-

Models available in 30T, 40T, and 60T, supporting multi-stage programmable pressing for accuracy.

-

Equipped with a 7" LCD touch screen, enabling intuitive control of pressure, dwell time, and sequence.

-

Molded from 400C high-hardness die steel with quench hardness 85°, ensuring durability and precision.

-

Safety enhanced with a 6 mm plexiglass door and high-strength aluminum oxide plate.

-

Built to integrate smoothly with other lab supplies for research, testing, and quality control workflows.

Applications

Ideal for producing XRF fluorescent tablets in environmental, chemical, or materials science laboratories. The consistent performance reflects the expertise of professional hydraulic press machines designers.

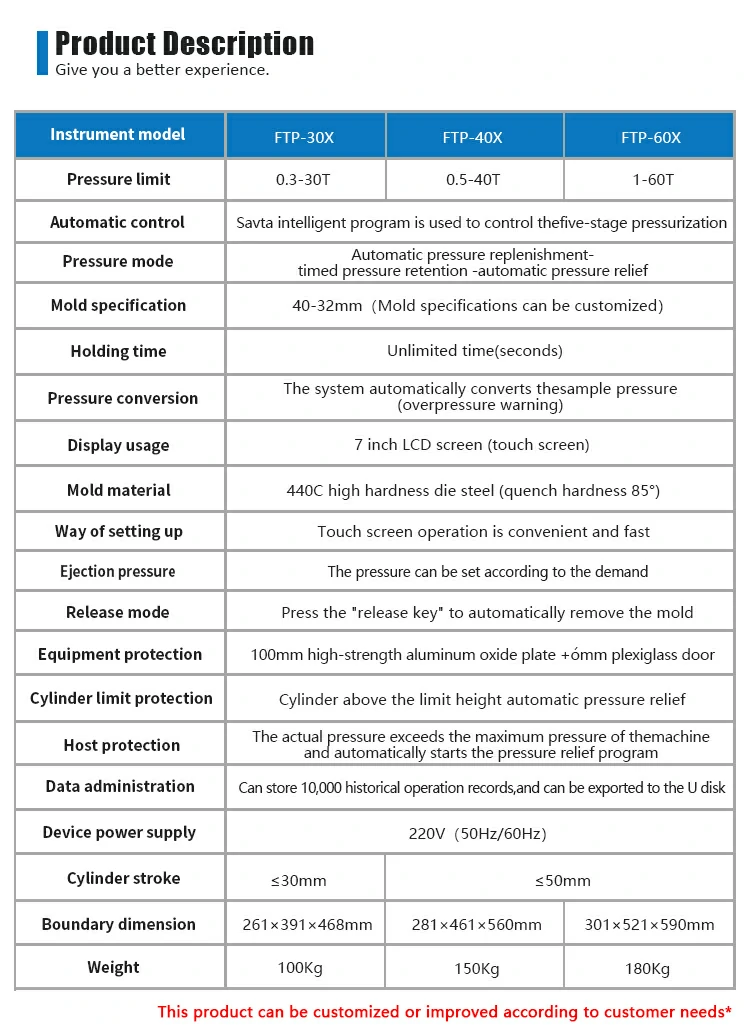

Product Description

Instrument model FTP-30X FTP-40X FTP-60X Pressure limit 0.3-30T 0.5-40T 1-60T Automatic control Savta intelligent program is used to control the five-stage pressurization Pressure mode Automatic pressure replenishment-timed pressure retention-automatic pressure relief Mold specification 40-32mm (Mold specifications can be customized) Holding time Unlimited time(seconds) Pressure conversion The system automatically converts the sample pressure (overpressure warning) Display usage 7 inch LCD screen (touch screen) Mold material 440C high hardness die steel (quench hardness 85°) Way of setting up Touch screen operation is convenient and fast Ejection pressure The pressure can be set according to the demand Release mode Press the "release key" to automatically remove the mold Equipment protection 100mm high-strength aluminum oxide plate +6mm plexiglass door Cylinder limit protection Cylinder above the limit height automatic pressure relief Host protection The actual pressure exceeds the maximum pressure of the machine and automatically starts the pressure relief program Data administration Can store 10,000 historical operation records, and can be exported to the U disk Device power supply 220V (50Hz/60Hz) Cylinder stroke ≤30mm ≤50mm Boundary dimension 261×391×468mm 281×461×560mm 301×521×590mm Weight 100Kg 150Kg 180Kg This product can be customized or improved according to customer needs*

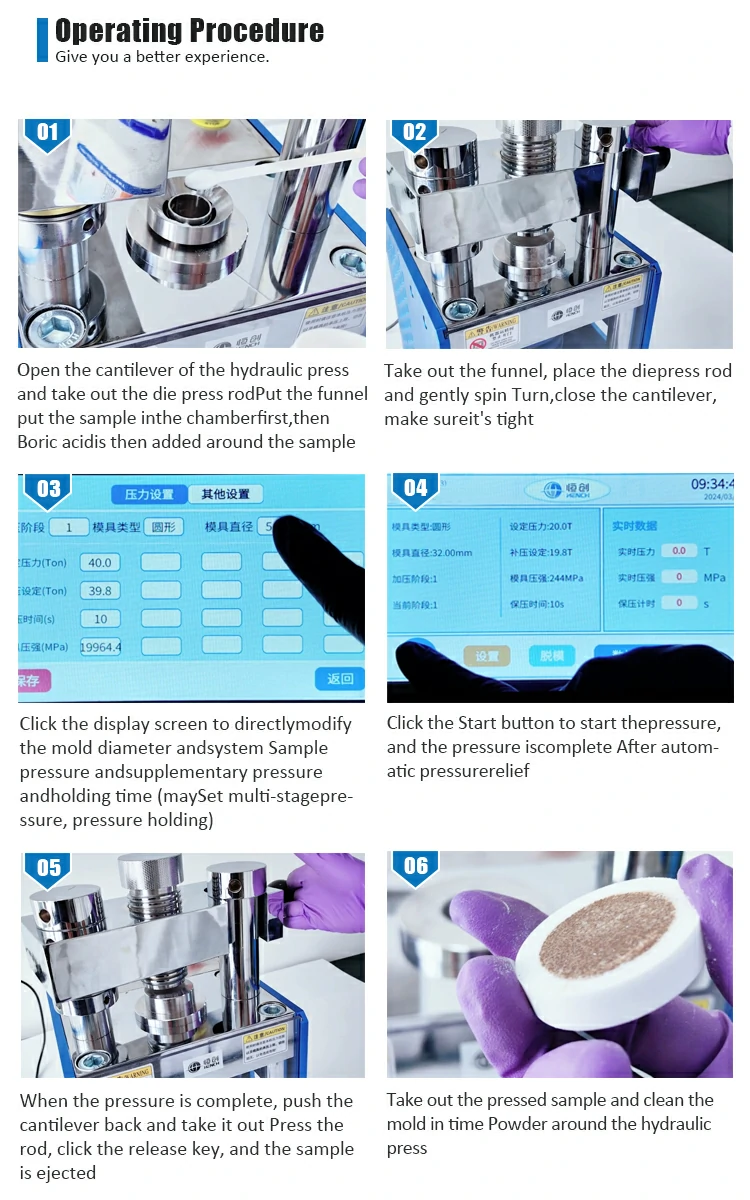

Operating Procedure

-

Open the cantilever of the hydraulic press and take out the die press rod. Insert the funnel, load the sample into the chamber, and then add boric acid around the sample.

-

Remove the funnel, place the die press rod, and gently rotate it. Close the cantilever and ensure it is tightened securely.

-

On the display screen, directly modify the mold diameter, system sample pressure, supplementary pressure, and holding time (multi-stage pressure and pressure holding can be set).

-

Click the Start button to begin pressurization. After reaching the set value, the system will automatically complete pressurization and pressure relief.

-

When pressurization is complete, push back the cantilever and remove the press rod. Click the Release key to eject the sample.

-

Remove the pressed sample and clean the mold promptly, along with any powder around the hydraulic press.

Why Choose Hench?

Hench Technology Co., Ltd., headquartered in Tianjin, China, is a leading hydraulic press supplier specializing in innovative laboratory and industrial presses. Hench’s solutions combine reliability, safety, and ease of use, making them trusted partners for labs worldwide.

-

-

65/100/150/200-ton Modular Automatic Powder Press Machine HAP-FS

Automatic Powder Press Machine Overview

The HAP-FS series is a high-capacity powder press machine designed for laboratories and industrial applications requiring precise and efficient powder pellet preparation. With models ranging from 65 to 200 tons, this modular hydraulic press offers programmable multi-stage pressing, automatic demolding, and a user-friendly interface, ensuring consistent and reproducible results.

Product features

The main application of HAP-FS split automatic split hydraulic press For samples that require high pressure to form,such as ceramics, Metal powder and other large size mold use.Adopt split-type knot structure automatic program operation: program pressure/five stages advanced-Pressure holding-pressure replenishment -timing pressure relief, etc.,using LCD touch scree. The operation is more intuitive and simple.

Automatic control: Savta intelligent program control 5 sections of pressure/optional 15 sections of pressure

Pressure die:Program automatic pressure -automatic pressure -timing pressure - automatic pressure relief

Dwell time:Unlimited time(N seconds)

Pressure conversion:The system automatically converts the sample pressure (overpressure warning)

Device display:7 "touch LCD screen/English interface can be switched

Equipment protection:6.5mm high strength steel plate +6mm Plexiglass protective door

Limit protection:Cylinder above the limit height automatic pressure relief

Host protection:Program pressure mechanical fault report emergency stop function, overpressure automatic pressure relief

Data administration:Can store 10,000 historical operation records, and can be exported to the U disk

Cylinder stroke:50mm

Ejection pressure:The pressure bearing range can be set by itself

Passive safety:Leakage protection + emergency stop switch

Intelligence operation:(Optional) Computer connection for remote operation/can be customized according to customer needs

Applications

The HAP-FS series is ideal for preparing powder pellets for various analytical techniques, including X-ray fluorescence (XRF) and Fourier-transform infrared (FTIR) spectroscopy. Its precise control and consistent performance make it suitable for applications in materials science, environmental testing, and quality control laboratories.

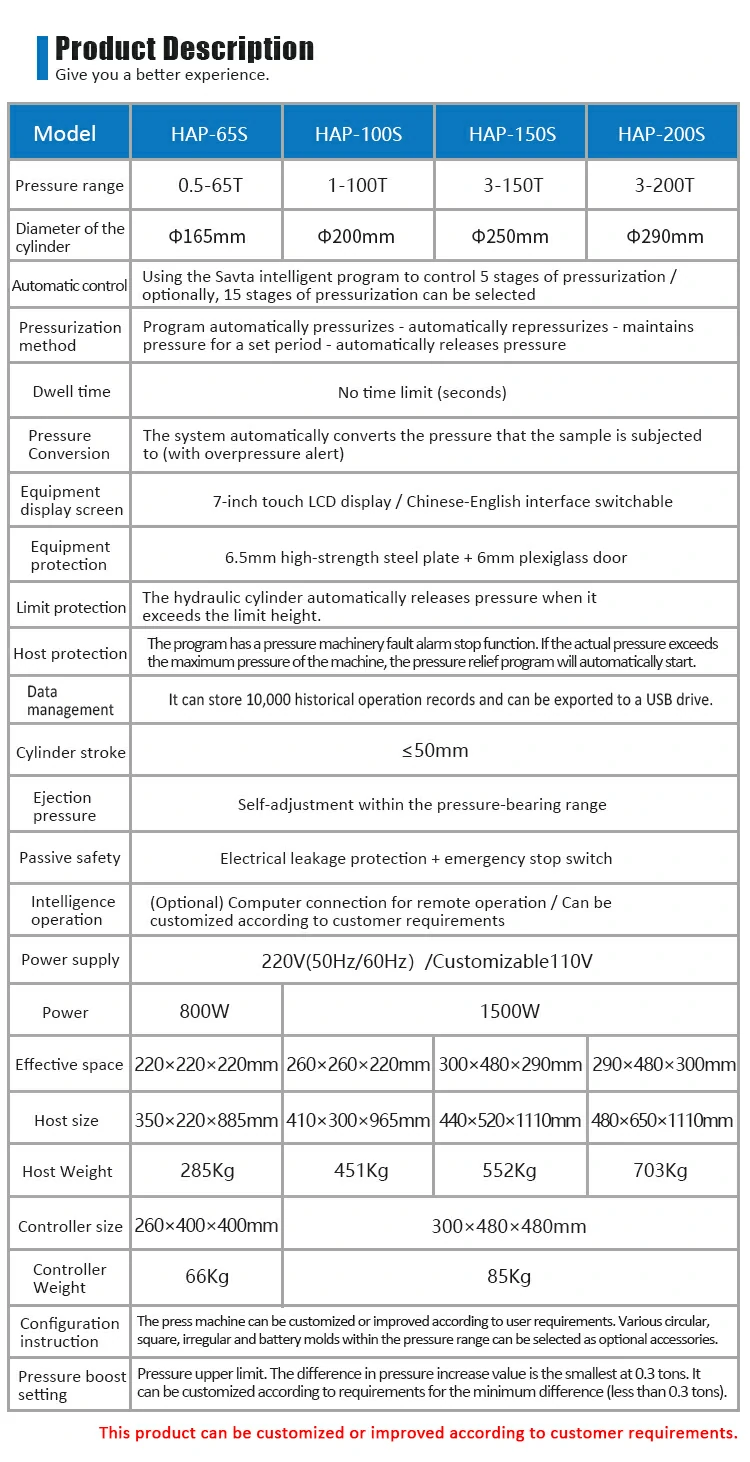

Product Description

Model HAP-65S HAP-100S HAP-150S HAP-200S Pressure range 0.5-65T 1-100T 3-150T 3-200T Diameter of the cylinder Φ165mm Φ200mm Φ250mm Φ290mm Automatic control Using the Savta intelligent program to control 5 stages of pressurization / optionally, 15 stages of pressurization can be selected Pressurization method Program automatically pressurizes - automatically repressurizes - maintains pressure for a set period - automatically releases pressure Dwell time No time limit (seconds) Pressure Conversion The system automatically converts the pressure that the sample is subjected to (with overpressure alert) Equipment display screen 7-inch touch LCD display / Chinese-English interface switchable Equipment protection 6.5mm high-strength steel plate + 6mm plexiglass door Limit protection The hydraulic cylinder automatically releases pressure when it exceeds the limit height. Host protection The program has a pressure machinery fault alarm stop function. If the actual pressure exceeds the maximum pressure of the machine, the pressure relief program will automatically start. Data management It can store 10,000 historical operation records and can be exported to a USB drive. Cylinder stroke ≤50mm Ejection pressure Self-adjustment within the pressure-bearing range Passive safety Electrical leakage protection + emergency stop switch Intelligence operation (Optional) Computer connection for remote operation / Can be customized according to customer requirements Power supply 220V(50Hz/60Hz) /Customizable110V Power 800W 1500W Effective space 220×220×220mm 260×260×220mm 300×480×290mm 290×480×300mm Host size 350×220×885mm 410×300×965mm 440×520×1110mm 480×650×1110mm Host Weight 285Kg 451Kg 552Kg 703Kg Controller size 260×400×400mm 300×480×480mm Controller Weight 66Kg 85Kg Configuration instruction The press machine can be customized or improved according to user requirements. Various circular, square, irregular and battery molds within the pressure range can be selected as optional accessories. Pressure boost setting Pressure upper limit. The difference in pressure increase value is the smallest at 0.3 tons. It can be customized according to requirements for the minimum difference (less than 0.3 tons). This product can be customized or improved according to customer requirements.

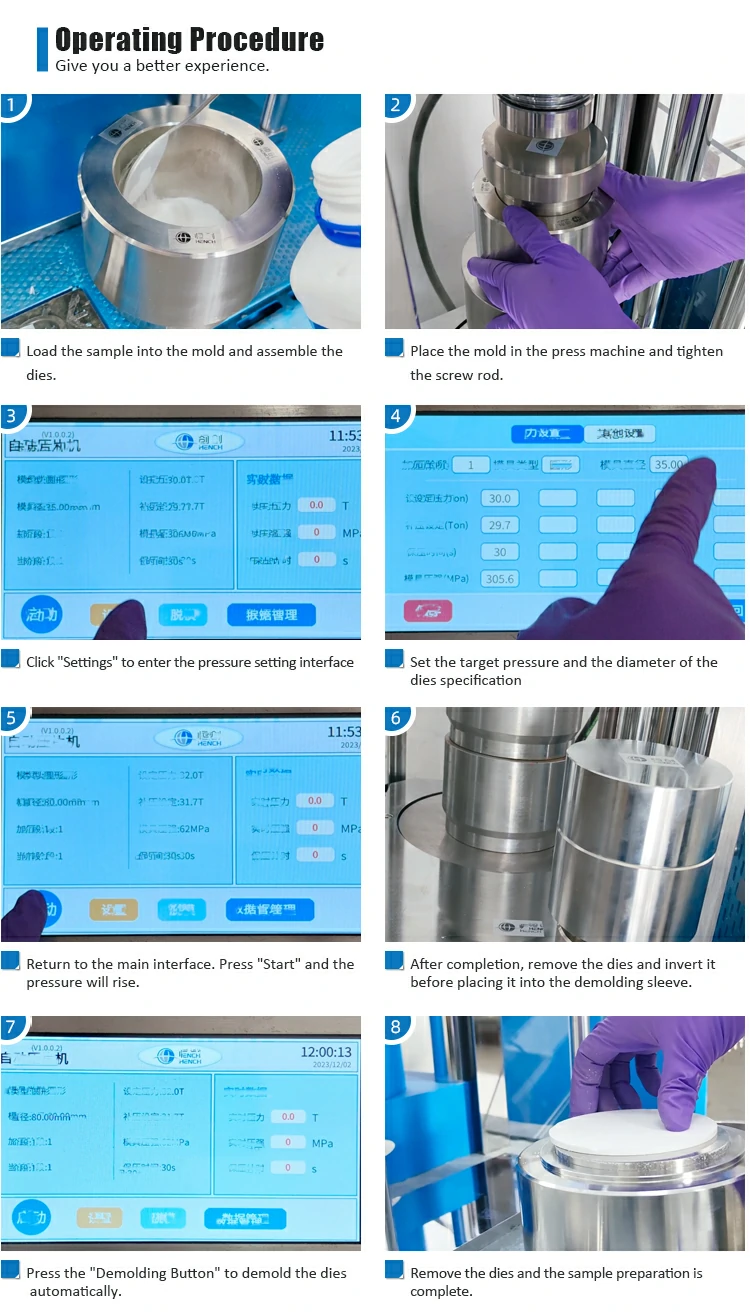

Operating Procedure

-

Load the sample into the mold and assemble the dies.

-

Place the mold in the press machine and tighten the screw rod.

-

Click "Settings" to enter the pressure setting interface.

-

Set the target pressure and the die diameter specification.

-

Return to the main interface and press "Start" to increase the pressure.

-

After completion, remove the dies, invert it, and place it into the demolding sleeve.

-

Press the "Demolding" button to demold the dies automatically.

-

Remove the dies, and the sample preparation is complete.

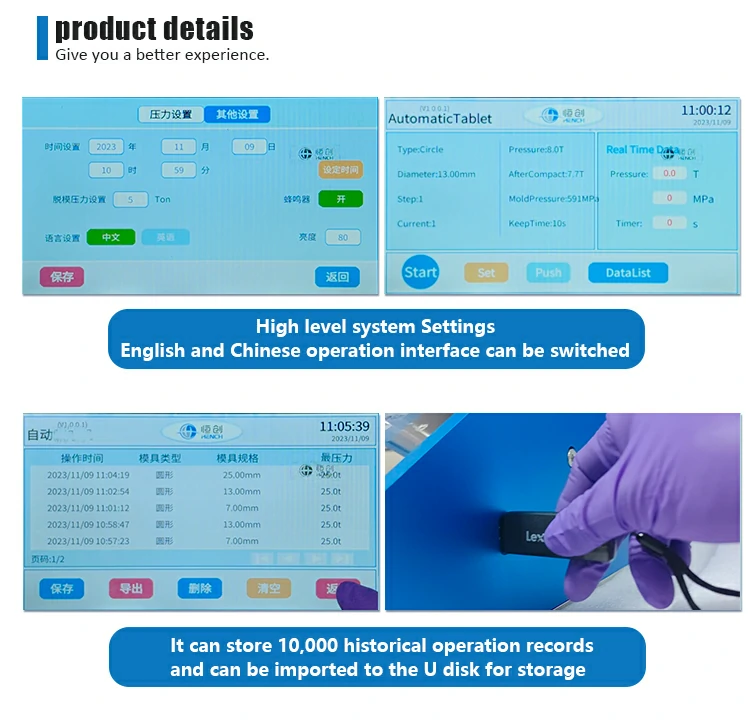

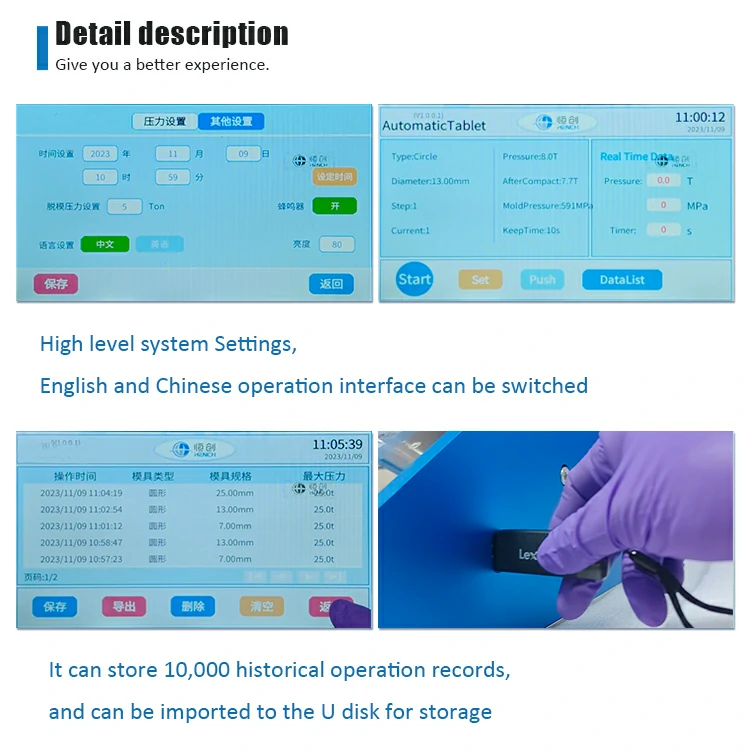

Detail Description

-

High-level system settings, with switchable English and Chinese operation interfaces.

-

Can store up to 10,000 historical operation records, which can be exported to a USB disk for storage.

Operation Interface

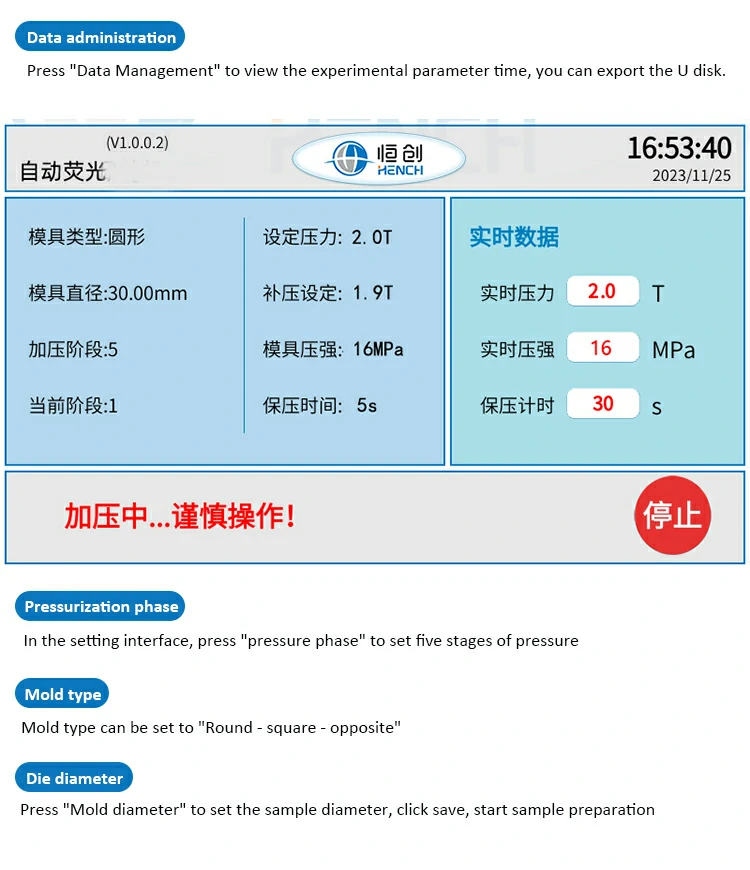

-

Setting

Under the operation interface, press Setting to enter the setting interface. Here you can set pressure, mold type, and sample parameters. -

Demould

Press the Release button to start. When the pressure exceeds the specified value or the limit switch is triggered, the device will automatically stop and relieve pressure. Manual screw operation is also available. -

Data Administration

Press Data Management to view experimental parameters and time records. Data can be exported to a USB disk. -

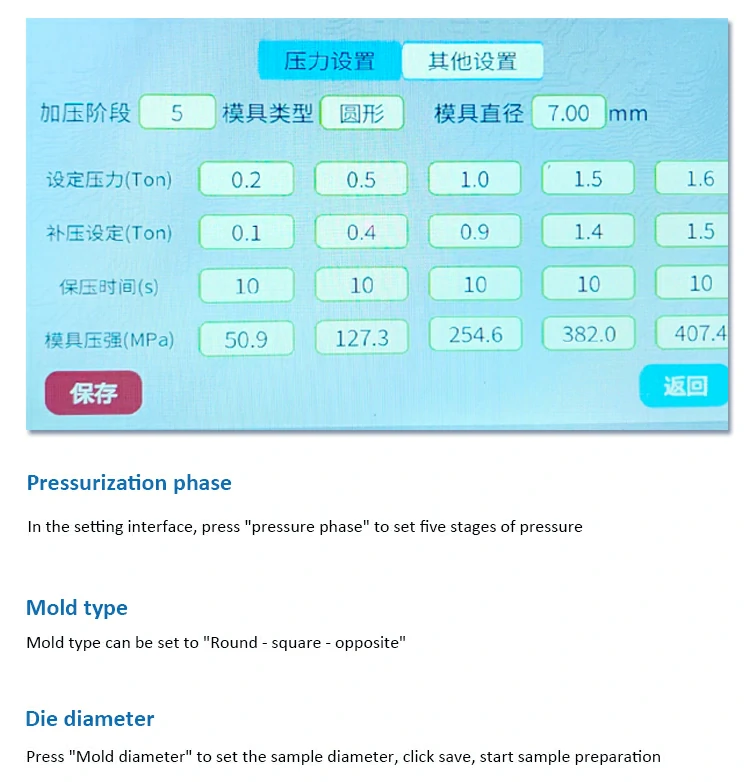

Pressurization Phase

In the setting interface, press Pressure Phase to configure up to five stages of pressure. -

Mold Type

The mold type can be set to Round, Square, or Opposite. -

Die Diameter

Press Mold Diameter to set the sample diameter, then click Save to start sample preparation.

About Hench Technology Co., Ltd.

Hench Technology Co., Ltd., based in Tianjin, China, is a leading hydraulic press supplier specializing in laboratory and industrial pressing solutions. With a commitment to innovation and quality, Hench provides a range of products, including the HAP-FS series, designed to meet the rigorous demands of modern laboratories and industrial applications.

-

High-Quality Laboratory Presses for Precise Sample Preparation

Hench Technology offers advanced laboratory presses that ensure accurate and reproducible results for a variety of laboratory applications. Designed for efficiency and reliability, these presses are ideal for powders, tablets, and other sample types.

Trusted Lab Equipment Supplier

As a professional lab equipment supplier, Hench Technology provides comprehensive solutions and technical support for laboratory operations. Our commitment to innovation and quality ensures that every laboratory press meets the highest standards.

.png)

.png)