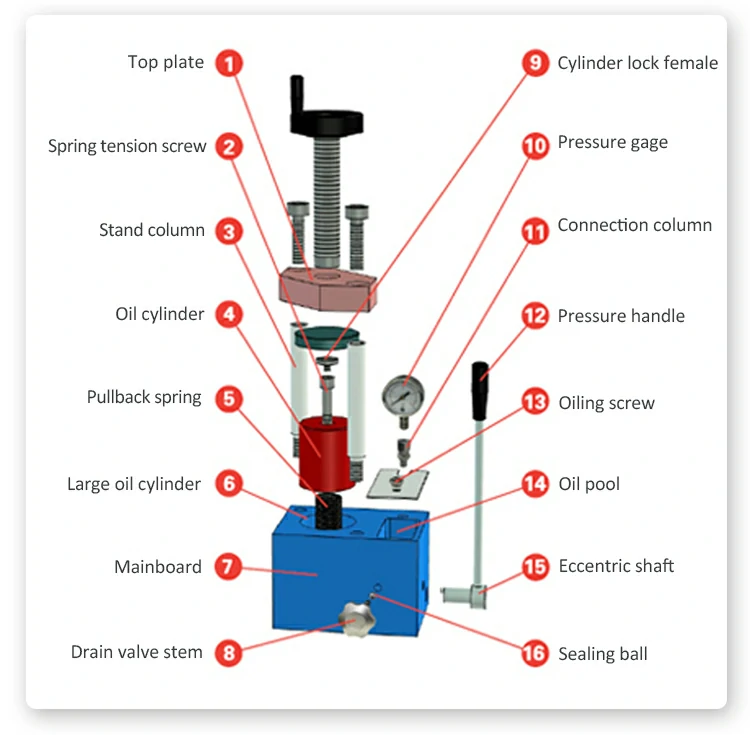

HYP-15 15-ton Manual IR Tablet Press Machine

Manual IR Tablet Press Machine Feature

The HYP-15 infrared tablet press adopts an integrated structure, with a fast upper pressing speed and no oil leakage.

It is suitable for pressing powder samples for infrared spectrometers. The use of imported plungers further enhances the stability of the product. It can be equipped with 7mm and 13mm infrared tablet molds. This product

It can be used in conjunction with all brands of Fourier Transform Infrared Spectrometers, such as: Beidian Rui Li, Tianjin Hongdong, Thermo from the United States, PE from the United States, Bruker from Germany, Shimadzu from Japan, etc.

Compatible with Various FTIR/XRF Spectrometers

This IR tablet press works seamlessly with all major FTIR/XRF spectrometer brands, including Beidian Rui Li, Tianjin Hongdong, Thermo (USA), PE (USA), Bruker (Germany), and Shimadzu (Japan). It can be equipped with 7 mm and 13 mm infrared pressing molds, making it versatile for different sample sizes. It also supports IR hydraulic press dies for easy and efficient sample pressing.

Stable, Durable, and Low Maintenance

The HYP-15 uses imported plungers to minimize oil leakage and enhance stability. Its pressure stability is ≤1 MPa/10 min, ensuring consistent performance and long-term reliability.

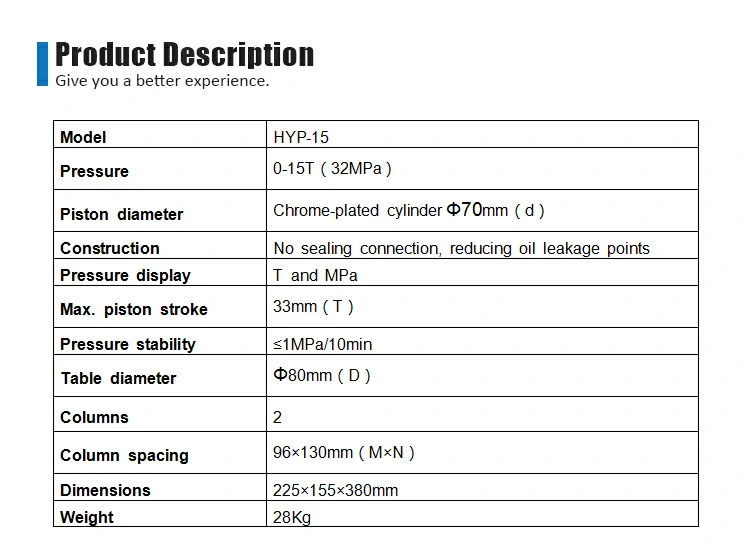

Product Description

| Item | Specification |

|---|---|

| Model | HYP-15 |

| Pressure | 0-15T (32MPa) |

| Piston diameter | Chrome-plated cylinder Φ70mm (d) |

| Construction | No sealing connection, reducing oil leakage points |

| Pressure display | T and MPa |

| Max. piston stroke | 33mm (T) |

| Pressure stability | ≤1MPa / 10min |

| Table diameter | Φ80mm (D) |

| Columns | 2 |

| Column spacing | 96 × 130mm (M × N) |

| Dimensions | 225 × 155 × 380mm |

| Weight | 28Kg |

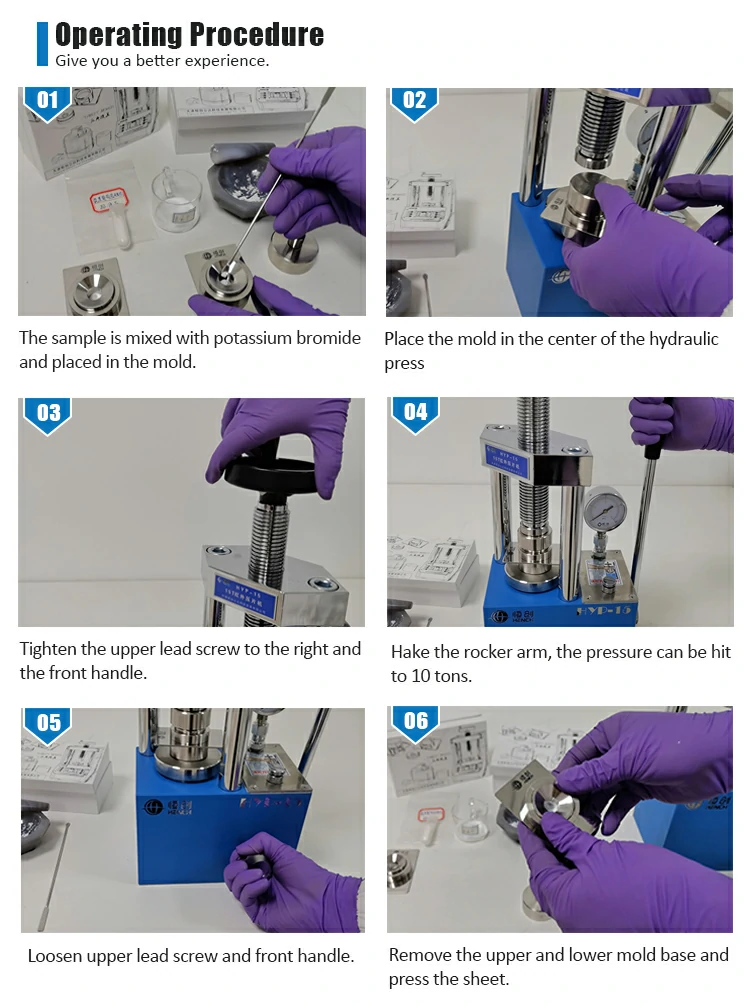

Operating Procedure

-

Mix the sample with potassium bromide and place it in the mold.

-

Place the mold in the center of the hydraulic press.

-

Tighten the upper lead screw to the right and secure the front handle.

-

Shake the rocker arm to apply pressure up to 10 tons.

-

Loosen the upper lead screw and the front handle.

-

Remove the upper and lower mold bases and press the sheet.

About Hench Technology

Hench Technology Co., Ltd., based in Tianjin, China, specializes in the design and manufacturing of infrared spectroscopy sample preparation equipment. Their product line includes IR hydraulic presses, molds, heated dies, and full accessory sets. As a trusted hydraulic press supplier, Hench provides durable, high-performance solutions for laboratories worldwide.