Hot Tablet Press Handheld YPH-800C

Overview

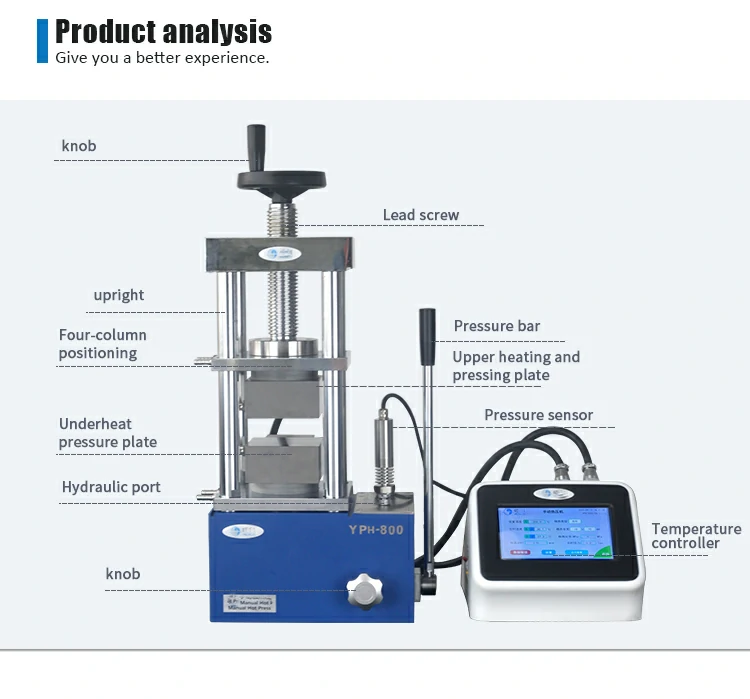

YPH series hot press adopts split structure, manual hydraulic drive, lead screw suspension heating plate, with fast pressure, easy to operate Easy maintenance and other advantages. Multi-stage temperature control can meet the needs of various powders, plastic films, rubber materials and solid materials for high temperature and high pressing samples.

Key Features

-

Integrated heating system ensures uniform temperature control, making it an effective heated hydraulic press for powders, polymers, and small sample materials.

-

Manual operation with smooth hydraulic pressing provides consistent results, reflecting the high standard expected of advanced hydraulic press machines.

-

Lightweight and portable, yet durable, featuring polished die surfaces and built-in thermal insulation to ensure safe and efficient lab work.

-

Low power consumption and easy maintenance make it a practical choice for frequent use in research or small-scale production environments.

Applications

Perfect for pressing small tablets or pellets in laboratories, R&D centers, or educational facilities. Often used alongside other lab supplies for sample preparation and analysis, this handheld press ensures precision and repeatability.

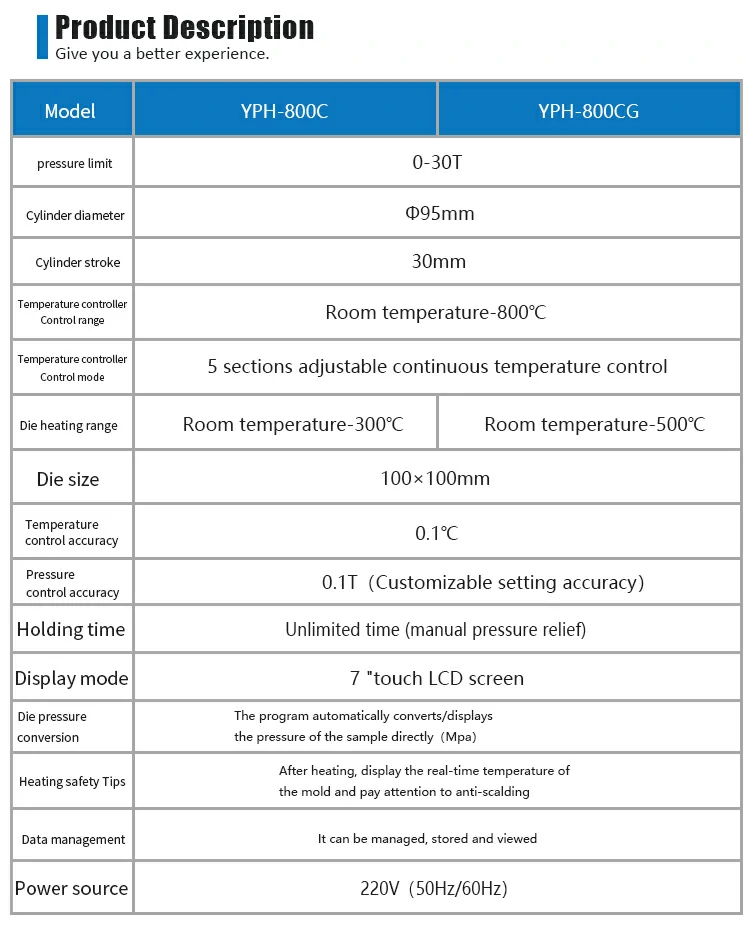

Product Description

| Model | YPH-800C | YPH-800CG |

| pressure limit | 0-30T | |

| Cylinder diameter | Φ95mm | |

| Cylinder stroke | 30mm | |

| Temperature controller Control range | Room temperature-800∘C | |

| Temperature controller Control mode | 5 sections adjustable continuous temperature control | |

| Die heating range | Room temperature-300∘C | Room temperature-500∘C |

| Die size | 100x100mm | |

| Temperature control accuracy | 0.1∘C | |

| Pressure control accuracy | 0.1T (Customizable setting accuracy) | |

| Holding time | Unlimited time (manual pressure relief) | |

| Display mode | 7 "touch LCD screen | |

| Die pressure conversion | The program automatically converts/displays the pressure of the sample directly (Mpa) | |

| Heating safety Tips | After heating, display the real-time temperature of the mold and pay attention to anti-scalding | |

| Data management | It can be managed, stored and viewed | |

| Power source | 220V (50Hz/60Hz) | |

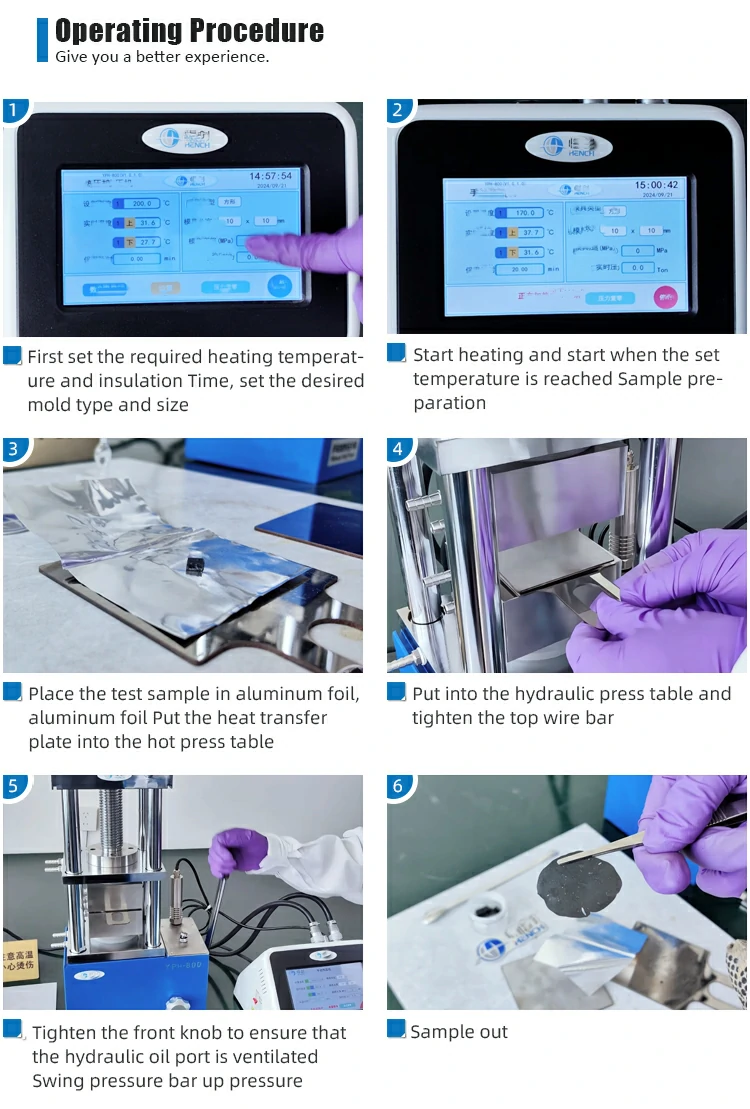

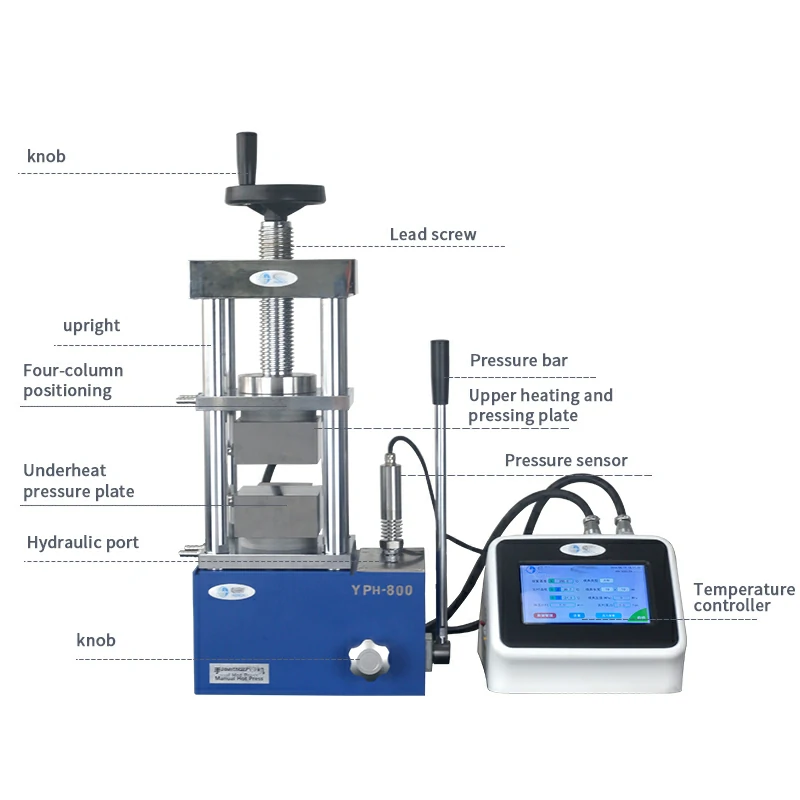

Operating Procedure

-

First, set the required heating temperature and insulation time, as well as the desired mold type and size.

-

Start heating, and begin sample preparation once the set temperature is reached.

-

Place the test sample in aluminum foil, then place the aluminum foil with the heat transfer plate onto the hot press table.

-

Insert it into the hydraulic press table and tighten the top screw bar.

-

Tighten the front knob to ensure the hydraulic oil port is ventilated, then swing the pressure bar upward to apply pressure.

-

Remove the prepared sample.

Why Hench?

Hench Technology Co., Ltd., headquartered in Tianjin, China, is a trusted hydraulic press manufacturer specializing in laboratory and industrial presses. Hench provides reliable hydraulic press machines designed for safety, performance, and ease of use. Their solutions support universities, laboratories, and industrial clients globally, backed by professional service and quality assurance.