What is FTIR Spectroscopy: Your Expert Guide to 5 Key Industrial Applications in 2025

December 26, 2025

Abstract

Fourier transform infrared (FTIR) spectroscopy is a versatile and non-destructive analytical technique that provides detailed information about the chemical composition and molecular structure of a sample. The method operates by irradiating a sample with a broad range of infrared light and measuring the absorption at specific wavelengths. Each chemical bond within a molecule vibrates at a characteristic frequency, and when the frequency of the IR radiation matches the vibrational frequency of a bond, the radiation is absorbed. An FTIR spectrometer collects these absorption data simultaneously across a wide spectral range using a Michelson interferometer. The raw data, an interferogram, is then converted into an absorption spectrum through a mathematical process known as a Fourier transform. This resulting spectrum serves as a unique molecular "fingerprint," allowing for the identification and quantification of organic and sometimes inorganic compounds in solid, liquid, or gaseous states. Its speed, precision, and sensitivity make it an indispensable tool across diverse fields.

Key Takeaways

- FTIR identifies chemical bonds by measuring a sample's absorption of infrared light.

- The technique generates a unique spectral fingerprint for molecular identification.

- It is a rapid, non-destructive method suitable for solids, liquids, and gases.

- Understanding what is FTIR spectroscopy helps in quality control and research.

- The Michelson interferometer allows for the simultaneous collection of all frequencies.

- Data is processed from an interferogram to a spectrum via a Fourier transform.

- Key applications include polymer analysis, pharmaceuticals, and environmental monitoring.

Table of Contents

- The Fundamental Principles of FTIR Spectroscopy

- Comparing Key FTIR Measurement Techniques: ATR, Transmission, and Reflection

- Application 1: Pharmaceutical Quality Control and Drug Development

- Application 2: Polymer and Plastics Industry Analysis

- Application 3: Environmental Monitoring and Analysis

- Application 4: Semiconductor and Electronics Manufacturing

- Application 5: Forensics and Material Conservation

- Advanced Data Processing and Spectral Interpretation

- Frequently Asked Questions (FAQ)

- Conclusion

- References

The Fundamental Principles of FTIR Spectroscopy

To truly grasp the capabilities of Fourier Transform Infrared (FTIR) spectroscopy, one must first journey into the molecular world, a realm where everything is in constant motion. Imagine molecules not as static collections of atoms, but as dynamic entities where chemical bonds stretch, bend, and twist. FTIR spectroscopy is our window into observing these minute, yet profoundly informative, movements. It is an analytical conversation between light and matter, where we send in a pulse of infrared energy and listen to the molecular response.

From Light Waves to Molecular Vibrations: A Conceptual Overview

At the heart of all matter are atoms linked by chemical bonds, which can be visualized as springs. Just as a spring has a natural frequency at which it oscillates, a chemical bond has a natural frequency at which it vibrates. These vibrations are not random; they are quantized, meaning they can only occur at specific energy levels, much like the rungs of a ladder. When a molecule is exposed to infrared radiation, it can absorb energy. A condition for this absorption is that the frequency of the incoming light must precisely match the frequency of one of the molecule's fundamental vibrational modes. When a match occurs, the molecule jumps to a higher vibrational energy state, and the spectrometer records a decrease in light intensity at that specific frequency.

Consider a simple molecule like carbon dioxide (CO2). Its bonds can undergo several types of vibrations: a symmetric stretch, where both oxygen atoms move away from and toward the central carbon atom in unison; an asymmetric stretch, where one oxygen atom moves toward the carbon while the other moves away; and bending vibrations, where the bond angle changes. Each of these vibrational modes corresponds to a different energy level and will therefore absorb a different frequency of infrared light.

The resulting plot of absorption versus frequency (or more commonly, wavenumber, expressed in reciprocal centimeters, cm⁻¹) is an infrared spectrum. This spectrum is not just a random series of peaks; it is a unique fingerprint of the molecule. A peak at a specific wavenumber indicates the presence of a particular type of chemical bond or functional group. For instance, a strong, broad absorption around 3300 cm⁻¹ is a classic indicator of an O-H bond, as found in alcohols and water. A sharp, intense peak near 1700 cm⁻¹ typically signals a C=O (carbonyl) group, a key component of ketones, aldehydes, and esters. By analyzing the positions, intensities, and shapes of these absorption bands, a chemist can deduce the molecular structure of an unknown compound or verify the identity of a known one (Infinita Lab, 2021).

The Michelson Interferometer: The Heart of the Spectrometer

Older dispersive infrared spectrometers worked by scanning through the wavelengths one by one, a process that was slow and often resulted in a low signal-to-noise ratio. The innovation that gives FTIR its name and its power is the use of a Michelson interferometer, an elegant optical device that allows for the measurement of all infrared frequencies simultaneously. This is known as the multiplex or Fellgett's advantage.

Let us construct a mental model of this device. Imagine a beam of infrared light from a source. This beam first encounters a beamsplitter, a special optical component that transmits approximately 50% of the light and reflects the other 50%.

- The transmitted portion of the beam travels to a fixed mirror and is reflected directly back to the beamsplitter.

- The reflected portion of the beam travels to a moving mirror, which translates back and forth along the path of the light. It is also reflected back to the beamsplitter.

When these two beams return to the beamsplitter, they recombine. Part of this recombined beam is directed toward the sample and, ultimately, the detector, while the other part is directed back toward the source. The key to the interferometer's function is the path difference between the two beams. The distance the light travels in the moving mirror's arm changes continuously. The difference in the distance traveled by the two beams is called the Optical Path Difference (OPD) (Newport, 2025).

When the two mirrors are at an equal distance from the beamsplitter, the OPD is zero (a condition known as Zero Path Difference, or ZPD). At ZPD, the two beams travel identical path lengths. For every wavelength of light, the two beams recombine perfectly in phase, leading to constructive interference. This results in a strong signal at the detector—the maximum intensity possible.

As the moving mirror travels away from the ZPD position, an OPD is introduced. Now, the two beams travel different distances before recombining. For a given wavelength, whether the interference is constructive, destructive, or somewhere in between depends on the exact OPD. If the OPD is an integer multiple of the wavelength (λ, 2λ, 3λ…), constructive interference occurs. If the OPD is a half-integer multiple (λ/2, 3λ/2, 5λ/2…), destructive interference occurs, and the signal for that wavelength is canceled out. The detector measures the total intensity of all wavelengths of the recombined beam at each position of the moving mirror.

The Interferogram: Capturing the Spectral Information

As the moving mirror scans, the detector records a signal that varies in intensity as a function of the Optical Path Difference. This raw data plot of intensity versus OPD is called an interferogram. It does not look like a conventional spectrum with peaks. Instead, for a broadband infrared source, it appears as a sharp, intense spike at the ZPD (the "centerburst") where all frequencies interfere constructively, followed by a complex pattern of oscillations that decay as the OPD increases (Newport, 2025).

Think of the interferogram as a complex sound wave that contains many different musical notes (frequencies) all played at once. The centerburst is the moment when all those notes start in perfect harmony. As time progresses (analogous to increasing OPD), the different notes go in and out of phase with each other, creating a complicated waveform. The interferogram is the time-domain representation of the spectral information; it holds all the frequency information, but in a scrambled, encoded format. Every single data point in the interferogram contains information about every single infrared frequency in the spectrum.

The precision of the moving mirror's movement is paramount for acquiring a high-quality spectrum. To track the mirror's position with extreme accuracy, a secondary interferometer system using a helium-neon (HeNe) laser is often built into the instrument. The laser produces a simple sinusoidal interferogram that acts as an internal ruler, allowing the instrument to sample the main infrared interferogram at precise intervals. This is known as Connes' advantage, which ensures superior wavenumber accuracy compared to dispersive instruments.

The Fourier Transform: From Time Domain to Frequency Domain

The final, crucial step is to decode the interferogram to produce a familiar spectrum of absorbance versus wavenumber. This is accomplished using a mathematical algorithm called the Fourier Transform (FT). The discovery of an efficient version of this algorithm, the Fast Fourier Transform (FFT), in the 1960s was the computational breakthrough that made modern FTIR spectroscopy practical.

The Fourier transform is a mathematical tool that decomposes a signal from the time domain (like the interferogram, which is a function of OPD, a proxy for time) into its constituent frequencies in the frequency domain. Returning to our music analogy, the Fourier transform is the process that would take the complex sound wave and tell you exactly which musical notes (frequencies) are present and how loud (intensity) each one is.

The computer in the FTIR spectrometer performs this calculation on the digitized interferogram. The result is a single-beam spectrum, which shows the intensity of light at each wavenumber. This spectrum contains features from the source, the atmosphere (water vapor and CO2 have strong IR absorptions), and the instrument itself. To obtain a spectrum of just the sample, two measurements are required:

- Background Spectrum: An interferogram is collected with no sample in the beam path. After the Fourier transform, this gives a background spectrum, I₀.

- Sample Spectrum: An interferogram is collected with the sample placed in the beam path. The Fourier transform of this gives the sample spectrum, I.

The final transmittance spectrum (T) is calculated by taking the ratio of the sample spectrum to the background spectrum (T = I / I₀). This process effectively cancels out the instrumental and atmospheric contributions, leaving only the absorption features of the sample. This transmittance spectrum is often converted to an absorbance spectrum (A = -log(T)), because absorbance is directly proportional to the concentration of the sample, according to the Beer-Lambert law. The result is the clean, interpretable molecular fingerprint that is the ultimate goal of the analysis.

Comparing Key FTIR Measurement Techniques: ATR, Transmission, and Reflection

Once an understanding of the fundamental principles of FTIR spectroscopy is established, the next practical consideration is how to introduce the sample to the infrared beam. The choice of sampling technique is not trivial; it profoundly impacts the quality of the data and the type of information obtained. The three most common measurement modes are Transmission, Attenuated Total Reflectance (ATR), and Reflection. Each has its own set of strengths and is suited for different types of samples. Selecting the appropriate technique is akin to choosing the right tool for a specific job; the right choice ensures an efficient and accurate analysis, while the wrong one can lead to frustration and poor results.

Transmission Spectroscopy: The Classic Approach

Transmission is the oldest and most conceptually straightforward sampling method in infrared spectroscopy. In this mode, the infrared beam passes directly through the sample. The detector then measures the amount of light that is transmitted at each wavenumber. The portion of light that is not transmitted is either absorbed by the sample or scattered away from the detector.

Sample Preparation: The success of transmission analysis hinges on preparing a sample that is thin enough to allow a sufficient amount of light to pass through. If the sample is too thick or too concentrated, it will absorb all the infrared light, resulting in a "blackout" spectrum with no usable information.

- Liquids: Can be analyzed by placing a thin film of the liquid between two infrared-transparent salt plates (e.g., NaCl or KBr) or by using a liquid cell of a known pathlength.

- Solids: Powders are typically analyzed by grinding a small amount of the sample with a dry infrared-transparent salt, most commonly potassium bromide (KBr). The mixture is then pressed under high pressure to form a thin, transparent pellet. Alternatively, a solid can be dissolved in a suitable solvent to be analyzed as a liquid, or a mull can be prepared by grinding the solid with a drop of mineral oil (e.g., Nujol) to form a paste, which is then spread between salt plates.

- Films: Thin polymer films can often be mounted directly in the beam path without further preparation.

- Gases: Are analyzed using a gas cell, which is a long tube with IR-transparent windows at both ends, allowing the beam to travel through a long pathlength of the gas to achieve sufficient absorption.

Advantages and Disadvantages: Transmission is a highly quantitative technique due to the well-defined pathlength, making it ideal for concentration studies that rely on the Beer-Lambert law. The availability of extensive spectral libraries collected using transmission makes it a reliable method for compound identification. However, the sample preparation can be laborious and time-consuming, especially the creation of KBr pellets, which requires skill and can be affected by moisture.

Attenuated Total Reflectance (ATR): Probing the Surface

Attenuated Total Reflectance (ATR) has become the most popular sampling technique for FTIR in recent years due to its simplicity and versatility. It is a surface-sensitive technique that requires minimal to no sample preparation for most solids and liquids.

Principle of Operation: In an ATR setup, the infrared beam is directed into a crystal of high refractive index, such as zinc selenide (ZnSe), germanium (Ge), or diamond. The beam is angled in such a way that it undergoes total internal reflection at the interface between the crystal and the sample, which is pressed into firm contact with the crystal surface. Although the beam is "totally" reflected, an electromagnetic wave known as an evanescent wave penetrates a short distance (typically 0.5 to 2 micrometers) into the sample (Covalent Metrology, 2025). If the sample absorbs at a particular frequency, the evanescent wave will be attenuated (weakened). The beam may reflect multiple times within the crystal before exiting and heading to the detector. The resulting ATR spectrum is similar to a conventional transmission spectrum but not identical. The penetration depth of the evanescent wave is dependent on the wavelength of light, the refractive indices of the crystal and the sample, and the angle of incidence. This dependency causes peaks at higher wavenumbers (shorter wavelengths) to appear weaker in an ATR spectrum compared to a transmission spectrum. Modern FTIR software includes corrections to make ATR spectra look more like their transmission counterparts for easier library searching.

Advantages and Disadvantages: The primary advantage of ATR is its ease of use. Solid or liquid samples are simply placed on the crystal surface and pressure is applied to ensure good contact. This eliminates the need for grinding, pressing pellets, or using solvents. It is also non-destructive. ATR is excellent for analyzing thick or highly absorbing materials, like black rubber or dark plastics, that are impossible to measure in transmission. The main limitation is that it is a surface technique; it only analyzes the top few micrometers of a sample. This can be a disadvantage if the bulk composition differs from the surface, such as in a coated or weathered material. However, it is an advantage when the surface itself is the object of interest.

Reflection Spectroscopy: For Surfaces and Thin Films

Reflection techniques are used to analyze surfaces and films on reflective substrates. There are two main types: specular reflection and diffuse reflection.

Specular Reflection: This technique is used for analyzing smooth, reflective surfaces, such as a thin polymer coating on a metal mirror or a residue on a polished silicon wafer. The infrared beam is reflected from the sample surface at a specific angle, and the reflected light is collected by the detector. For very thin films on metallic substrates, a technique called grazing angle reflection-absorption is often used, where the beam strikes the surface at a very high angle of incidence (e.g., 80-85°) to enhance the signal from the film.

Diffuse Reflection: Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) is used for analyzing rough-surfaced solids and powders. When the infrared beam strikes a rough surface, some of it is specularly reflected, while the rest penetrates the sample and is then scattered in multiple directions—this is the diffuse component. DRIFTS optics are designed to collect this diffusely scattered light while minimizing the collection of the specular component. For analysis, a powdered sample is often diluted with a non-absorbing powder like KBr. DRIFTS is particularly useful for highly scattering samples that are difficult to analyze by other means.

Advantages and Disadvantages: Reflection methods are ideal for analyzing surfaces and coatings in-situ without altering the sample. Specular reflection is a powerful tool in the semiconductor industry for characterizing thin films. DRIFTS is excellent for powders and catalysts. The main challenge with reflection techniques is that the resulting spectra can be complex and distorted compared to transmission spectra, making interpretation and library searching more difficult. The appearance of the spectrum can be highly dependent on factors like particle size, packing density, and surface roughness.

A Comparative Table: Choosing Your Method

To aid in the selection process, the following table summarizes the key characteristics of each technique. Thinking about the nature of your sample—its physical form, thickness, and the part you wish to analyze (surface or bulk)—will guide you to the most suitable method.

| Feature | Transmission | Attenuated Total Reflectance (ATR) | Reflection (Specular/Diffuse) |

|---|---|---|---|

| Principle | IR beam passes through the sample. | Evanescent wave penetrates the sample surface. | IR beam reflects off the sample surface. |

| Sample Type | Transparent solids, liquids, gases, thin films. | Opaque or thick solids, liquids, powders, pastes, films. | Coatings on reflective surfaces, powders, rough solids. |

| Sample Prep | Can be extensive (KBr pellets, mulls, dilution). | Minimal; requires good contact with the crystal. | Minimal for specular; powders may need dilution for DRIFTS. |

| Analysis Zone | Bulk of the sample. | Surface (typically 0.5-2 µm deep). | Surface or near-surface. |

| Quantitation | Excellent; follows Beer-Lambert law well. | Good; requires corrections for pathlength dependency. | Difficult; spectra can be distorted. |

| Key Advantage | Strong quantitative data, large spectral libraries. | Speed, ease of use, versatility for many sample types. | Non-contact analysis of surfaces and films. |

| Key Limitation | Difficult for opaque or thick samples; sample prep. | Surface-only analysis; crystal can be damaged. | Spectra can be complex and hard to interpret. |

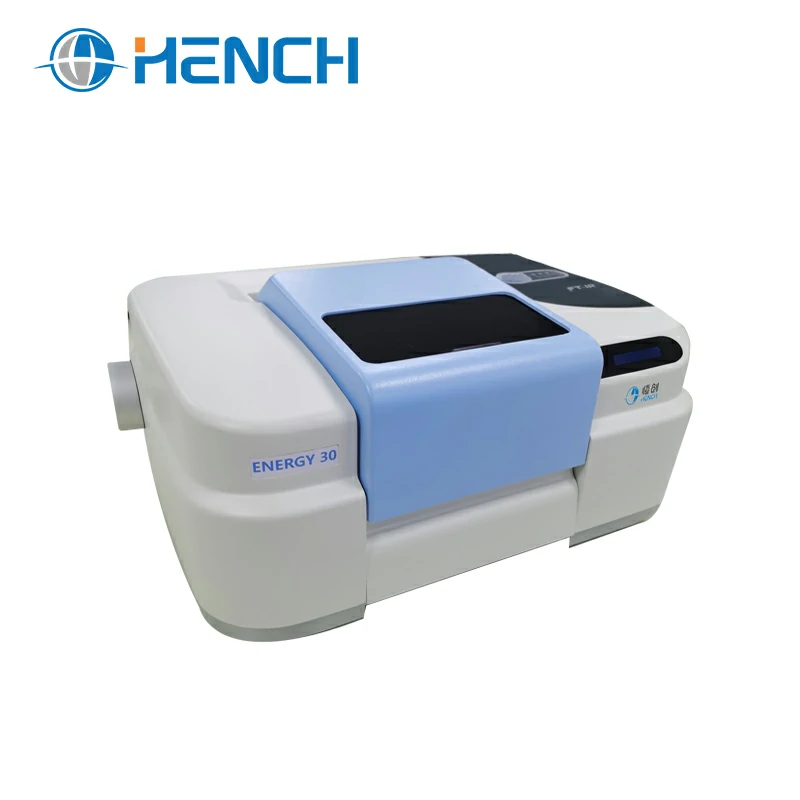

Choosing the right sampling accessory is a critical step in any FTIR analysis. While ATR has become a workhorse for general-purpose analysis, transmission remains the gold standard for quantitative measurements, and reflection techniques offer unique capabilities for surface-specific problems. A well-equipped laboratory will often have access to a variety of these tools, allowing the analyst to select the perfect approach for any given sample. For those looking to equip their labs, exploring a selection of high-performance infrared spectrometer solutions can provide options tailored to these diverse analytical needs.

Application 1: Pharmaceutical Quality Control and Drug Development

In the highly regulated world of pharmaceuticals, precision, accuracy, and consistency are not merely goals; they are absolute necessities. The health and safety of patients depend on the unwavering quality of every tablet, capsule, and injection. In this context, FTIR spectroscopy emerges as a powerful and indispensable analytical tool. Its ability to provide rapid, non-destructive, and chemically specific information makes it a cornerstone of quality control (QC) and research and development (R&D) throughout the drug manufacturing lifecycle, from raw material inspection to final product verification.

Ensuring Purity and Potency of Active Pharmaceutical Ingredients (APIs)

The journey of a drug begins with its Active Pharmaceutical Ingredient (API), the substance responsible for the drug's therapeutic effect. Before an API can be used in a formulation, its identity and purity must be unequivocally confirmed. FTIR spectroscopy provides an ideal method for this verification.

Every API has a unique molecular structure, which in turn gives it a unique infrared spectrum—its molecular fingerprint. A pharmaceutical QC laboratory will maintain a library of reference spectra for all the raw materials it uses. When a new batch of an API arrives, a small sample is analyzed using FTIR, often with a simple ATR accessory that requires no sample preparation. The resulting spectrum is then compared against the reference spectrum in the library.

The comparison is typically performed by a computer algorithm that calculates a correlation or "match" score. A high match score (e.g., >95%) provides a high degree of confidence that the incoming material is indeed the correct substance. This process is incredibly fast, often taking less than a minute per sample, allowing for high-throughput screening of raw materials.

Furthermore, the FTIR spectrum can reveal the presence of impurities. If the incoming material is contaminated with another substance, extra peaks that do not appear in the reference spectrum will be visible. For example, if a batch of ibuprofen was contaminated with aspirin, the characteristic peaks of aspirin's ester group (~1750 cm⁻¹) and acetyl group would be detectable in the spectrum of the mixture. While FTIR is not always sensitive enough to detect very low-level impurities (for which techniques like chromatography are used), it is excellent for quickly identifying gross contamination or material mix-ups, preventing incorrect ingredients from entering the manufacturing process.

Monitoring Polymorphism in Drug Formulation

Many APIs can exist in different solid-state forms, known as polymorphs. Polymorphs have the same chemical composition but differ in their crystal lattice arrangement. This may seem like a subtle difference, but it can have profound consequences for a drug's properties, including its solubility, dissolution rate, and bioavailability—how much of the drug is absorbed into the bloodstream. One polymorph might be highly effective, while another might be therapeutically inactive or even unstable.

Regulatory agencies like the U.S. Food and Drug Administration (FDA) require pharmaceutical companies to identify and control the polymorphic form of the API in the final drug product. Because the different crystal arrangements lead to slightly different intermolecular interactions, each polymorph produces a distinct infrared spectrum, particularly in the lower frequency "fingerprint" region (below 1500 cm⁻¹).

FTIR spectroscopy is therefore used extensively to monitor polymorphism. During drug development, it helps researchers identify which polymorph is the most stable and effective. During manufacturing, it is used as a QC check to ensure that the correct polymorphic form is present in the final tablets or capsules and that no unwanted polymorphic transformations have occurred during processes like milling, granulation, or compression. For example, the anti-ulcer drug ranitidine hydrochloride was discovered to exist in two polymorphic forms. Form 2 is the desired form for manufacturing, and FTIR provides a rapid method to confirm its presence and ensure the absence of Form 1.

Case Study: Identifying Counterfeit Medications

The global problem of counterfeit drugs poses a serious threat to public health. These fraudulent products may contain the wrong API, an incorrect dose of the API, or no API at all. They may also contain harmful contaminants. FTIR spectroscopy, particularly with the advent of portable and handheld devices, has become a frontline tool for customs officials, regulatory inspectors, and field workers to quickly screen for counterfeit medications.

Consider a scenario where a regulatory agency seizes a shipment of suspected counterfeit antimalarial tablets, which are supposed to contain the API artesunate. A conventional analysis would require sending the tablets to a central laboratory for time-consuming chromatographic analysis. With a handheld FTIR spectrometer, an inspector can perform an on-the-spot analysis.

The inspector would first measure a genuine artesunate tablet to create a reference standard. Then, they would measure the suspect tablets. The analysis could reveal several outcomes:

- High Match: The spectrum of the suspect tablet closely matches the genuine standard, suggesting it likely contains the correct API at roughly the correct concentration.

- No Match / Wrong API: The spectrum is completely different from the standard but matches another compound in the device's library, for example, paracetamol (acetaminophen). This indicates a fraudulent product where a cheaper drug has been substituted.

- No API: The spectrum matches only the excipients (inactive ingredients like starch or lactose), indicating there is no active ingredient present.

- Low Match / Contaminated: The spectrum shows some peaks corresponding to artesunate but also other significant, unidentified peaks, suggesting the product is of poor quality or contains dangerous impurities.

This rapid screening capability allows authorities to quickly identify and intercept dangerous counterfeit products, preventing them from reaching patients. It is a powerful example of how FTIR spectroscopy directly contributes to public health and safety in the pharmaceutical domain.

Application 2: Polymer and Plastics Industry Analysis

The world of polymers is vast and varied, forming the backbone of countless products we use daily, from simple packaging films and beverage bottles to high-performance components in automobiles and aerospace. The properties of a polymer—its strength, flexibility, melting point, and chemical resistance—are directly tied to its chemical structure. FTIR spectroscopy serves as an essential analytical technique in the polymer industry, providing critical insights for material identification, quality assurance, failure analysis, and product development. Its ability to quickly characterize the molecular makeup of these long-chain molecules makes it an invaluable asset.

Material Identification and Verification

In a large-scale manufacturing environment, ensuring that the correct polymer resin is being used for a specific product is a fundamental quality control step. A mix-up of materials, for instance, using polypropylene instead of high-density polyethylene, could lead to product failure and costly recalls. FTIR is the go-to method for rapid polymer identification.

Each type of polymer has a unique repeating monomer unit, which results in a highly characteristic infrared spectrum.

- Polyethylene (PE) shows strong C-H stretching and bending absorptions.

- Polypropylene (PP) has a similar C-H signature but with distinctive splitting of peaks due to the methyl (-CH₃) groups.

- Polyethylene terephthalate (PET), used in beverage bottles, is easily identified by its strong carbonyl (C=O) peak around 1720 cm⁻¹ and C-O stretching peaks from the ester group.

- Polystyrene (PS) exhibits sharp peaks from the aromatic C-H bonds of its benzene rings.

Using an ATR-FTIR spectrometer, a QC technician can analyze a plastic pellet, a molded part, or a piece of film in seconds. By comparing the acquired spectrum to a library of known polymer spectra, the material can be positively identified. This is crucial not only for incoming raw material verification but also for sorting and recycling plastics, where separating different polymer types is essential for producing high-quality recycled material.

Quantifying Additives and Copolymers

Few plastics are pure polymers. Most are complex formulations containing a variety of additives designed to enhance their properties. These can include plasticizers to increase flexibility, UV stabilizers to prevent degradation from sunlight, antioxidants to protect against thermal degradation, and slip agents to reduce friction. The concentration of these additives must be carefully controlled to meet product specifications.

FTIR can be used to quantify these components. For example, in the production of flexible PVC, the concentration of plasticizer (often a phthalate compound) is critical. A calibration curve can be created by preparing standards with known concentrations of plasticizer in PVC and measuring their FTIR spectra. The height or area of a characteristic peak from the plasticizer (e.g., its carbonyl peak) is plotted against concentration. The concentration of plasticizer in unknown production samples can then be determined by measuring their spectra and using the calibration curve.

Similarly, FTIR is used to analyze copolymers, which are polymers made from two or more different types of monomers. For instance, ethylene-vinyl acetate (EVA) is a copolymer used in adhesives and foams. The ratio of ethylene to vinyl acetate determines the material's properties. The relative intensities of peaks unique to the vinyl acetate component (like the C=O peak) and the ethylene component (like a C-H bending mode) can be used to calculate the composition of the copolymer, ensuring it meets the required specifications for a given application.

Degradation Studies and Failure Analysis

Why did a plastic part crack, become brittle, or discolor? FTIR spectroscopy is a powerful tool for investigating the chemical changes that occur when polymers degrade. Degradation can be caused by exposure to heat, UV light, or chemicals. These environmental stressors cause chemical reactions in the polymer, such as chain scission (breaking of the polymer backbone) and oxidation.

Oxidation is a common degradation pathway for many polymers. It leads to the formation of carbonyl (C=O) groups within the polymer structure. An FTIR analysis of a degraded polymer will often show the appearance or growth of a broad absorption band in the carbonyl region (around 1700-1750 cm⁻¹). The intensity of this carbonyl peak can be used to quantify the extent of oxidation and degradation.

Case Scenario: Automotive Component Failure Imagine an automotive manufacturer is experiencing premature failure of a black plastic dashboard component, which is becoming brittle and cracking in vehicles used in hot, sunny climates. A failure analysis engineer would use FTIR to investigate the cause.

- Material Verification: The engineer would first use ATR-FTIR to confirm the material of the failed part. They would analyze a non-degraded section of the part and compare its spectrum to the material specification, confirming it is the correct polymer, for example, an acrylonitrile butadiene styrene (ABS) blend.

- Degradation Analysis: Next, the engineer would compare the spectrum from the cracked, brittle surface with the spectrum from the unexposed, bulk material. The spectrum from the degraded surface shows a prominent new peak in the carbonyl region, indicating significant oxidation. It might also show a decrease in the intensity of the peak associated with the butadiene component (~965 cm⁻¹), which is known to be the most susceptible part of the ABS polymer to UV and thermal degradation.

- Conclusion: The FTIR evidence strongly suggests that the failure is due to oxidative and UV degradation, likely caused by insufficient UV stabilizer in the polymer formulation. The manufacturer can then work with their material supplier to improve the formulation, preventing future failures. This demonstrates how FTIR provides actionable chemical insights that solve real-world engineering problems.

Application 3: Environmental Monitoring and Analysis

The health of our planet is a matter of increasing concern, and the ability to accurately monitor and analyze our air, water, and soil is fundamental to protecting it. Environmental science requires analytical tools that are sensitive, specific, and often portable enough to be used in the field. FTIR spectroscopy meets these needs, offering powerful capabilities for identifying and quantifying pollutants, from gaseous emissions to microscopic plastic particles. It has become an indispensable technique for regulatory agencies, environmental consultants, and research scientists working to understand and mitigate human impact on the environment.

Detecting Pollutants in Air and Water

FTIR is highly effective for the analysis of gaseous pollutants. Industrial smokestacks, vehicle exhausts, and agricultural operations release a complex mixture of gases into the atmosphere. An extractive FTIR system can be used to continuously monitor these emissions. In this setup, a gas stream is drawn into a long-path gas cell, which uses mirrors to reflect the infrared beam back and forth through the gas multiple times, creating a very long effective pathlength (sometimes hundreds of meters). This long pathlength allows for the detection of gases at very low concentrations (parts per million or even parts per billion levels).

FTIR can simultaneously identify and quantify multiple gases from a single spectrum, including regulated pollutants like carbon monoxide (CO), nitrogen oxides (NOx), sulfur dioxide (SO₂), and various volatile organic compounds (VOCs). This capability is a significant advantage over methods that can only measure one compound at a time. Portable FTIR analyzers are also used by first responders to identify unknown chemical clouds released during industrial accidents or spills.

In water analysis, FTIR can be used to detect organic contaminants like oil and grease. A common method involves extracting the organic pollutants from a water sample into a solvent (like tetrachloroethylene) that does not absorb infrared light in the region of interest. The extract is then analyzed by transmission FTIR. The intensity of the C-H stretching absorptions around 2900 cm⁻¹ is proportional to the total concentration of oil and grease in the original water sample.

Microplastics Identification in Ecosystems

One of the most pressing environmental challenges of the 21st century is the pervasive contamination of our oceans, rivers, and even soils with microplastics—tiny plastic particles less than 5 mm in size. These particles originate from the breakdown of larger plastic debris or are directly released from products like cosmetics and synthetic textiles. Understanding the sources, fate, and ecological impact of microplastics requires knowing what types of plastic they are.

FTIR spectroscopy is the leading technique for identifying the chemical composition of these microscopic particles. After separating the microplastic particles from an environmental sample (e.g., seawater, sediment, or fish tissue), they can be analyzed individually under an FTIR microscope. The microscope focuses the infrared beam onto a single particle, and the resulting spectrum is used to identify the polymer type by matching it against a spectral library. This allows researchers to determine, for example, that the microplastics in a particular beach sediment are predominantly composed of polyethylene (from bags and packaging), polypropylene (from ropes and containers), and polystyrene (from foam products).

This information is vital for tracing pollutants back to their sources and for understanding which types of plastic are most persistent and prevalent in the environment. Newer techniques like focal plane array (FPA) based micro-FTIR imaging allow for the rapid analysis of thousands of particles simultaneously, providing a comprehensive picture of the microplastic contamination on a filter paper.

Soil Contamination Analysis

Soil quality is essential for agriculture and ecosystem health. Contamination of soil with organic pollutants, such as petroleum hydrocarbons from leaking storage tanks or pesticides from agricultural runoff, can have long-lasting negative effects. FTIR offers a rapid screening method for assessing this type of contamination.

When a site is suspected of being contaminated with petroleum, for example, soil samples can be quickly analyzed on-site using a portable FTIR spectrometer with an ATR accessory. The soil is pressed against the ATR crystal, and the spectrum is recorded. The presence of hydrocarbons is clearly indicated by the strong C-H stretching bands between 2800 and 3000 cm⁻¹. While this on-site analysis may not be as precise as laboratory-based chromatographic methods, it provides immediate, semi-quantitative results.

Case Scenario: Rapid Site Assessment An environmental consulting firm is tasked with assessing a large, abandoned industrial site for potential petroleum contamination before it can be redeveloped. The traditional approach would be to take hundreds of soil samples and ship them to a lab, waiting days or weeks for results.

Instead, the team uses a portable FTIR analyzer. They divide the site into a grid and take a soil measurement at each grid point. The entire process takes only a few hours. The FTIR results are used to create a contamination map of the site, showing "hotspots" where hydrocarbon levels are high. This allows the team to focus their efforts, taking only a small number of targeted samples from the most contaminated areas for confirmatory laboratory analysis. This approach, guided by FTIR screening, saves a significant amount of time and money, accelerating the site remediation process. It demonstrates how FTIR serves as a practical, efficient tool for making informed environmental decisions.

Application 4: Semiconductor and Electronics Manufacturing

The semiconductor and electronics industry operates on a scale that is almost unimaginably small. The intricate circuits on a modern microprocessor involve features measured in nanometers. At this scale, even the slightest chemical contamination or deviation in material properties can lead to device failure. Consequently, the industry relies on highly sensitive analytical techniques to monitor its processes with extreme precision. FTIR spectroscopy has carved out a crucial niche in this high-tech world, providing vital information for characterizing the thin films, coatings, and materials that are the building blocks of all electronic devices.

Characterizing Thin Films and Coatings

Modern electronic components are built up layer by layer, using a variety of thin films with specific dielectric, conductive, or protective properties. These films can be polymers (like polyimides used as insulating layers), silicon oxides and nitrides, or anti-reflective coatings. The thickness and chemical composition of these films must be precisely controlled.

FTIR is widely used to characterize these films. For films deposited on a reflective substrate like a silicon wafer, specular reflection or grazing angle reflection techniques are employed. By analyzing the absorption bands, one can confirm the chemical identity of the film. For example, in a silicon dioxide (SiO₂) film, the position of the strong Si-O stretching peak can provide information about the film's stoichiometry and stress. For a silicon nitride (Si₃N₄) film, the Si-N and N-H stretching peaks can be monitored.

Furthermore, FTIR can be used to measure the thickness of these films. The spectrum of a thin film often exhibits an interference pattern, known as fringes, which looks like a sinusoidal wave superimposed on the absorption spectrum. The spacing between these fringes is related to the film's thickness. By measuring the fringe pattern, the thickness of films (typically in the range of 1 to 50 micrometers) can be calculated non-destructively. For certain materials like epitaxial silicon layers, the thickness can be determined with high precision, which is a critical parameter in semiconductor manufacturing.

Contamination Control on Silicon Wafers

The pristine surface of a silicon wafer is the canvas upon which microelectronic circuits are painted. Any unwanted particulate or molecular contamination on this surface can cause a defect that ruins the final device. The sources of contamination are numerous: residues from cleaning processes, outgassing from plastic components in the cleanroom, or even human contact.

FTIR spectroscopy is a powerful tool for identifying the nature of this microscopic contamination. An FTIR microscope can be used to focus the infrared beam onto a defect or particle as small as 10-20 micrometers. The resulting spectrum can identify the contaminant, helping to trace it back to its source.

- If the spectrum matches a silicone (polydimethylsiloxane), the source might be a silicone-based grease or sealant used in the manufacturing equipment.

- If the spectrum reveals an ester, it could be a phthalate plasticizer that has leached out of a PVC component or a plastic wafer carrier.

- If the spectrum shows peaks characteristic of amides (like those in proteins), the contamination could be from human skin or saliva.

By identifying the chemical nature of the contamination, engineers can take targeted corrective actions to eliminate the source, improving production yield and device reliability.

Failure Analysis of Electronic Components

When an electronic device fails, the cause is often a mystery that must be solved to prevent future occurrences. FTIR is a key technique in the failure analyst's toolkit, used to investigate the chemical aspects of the failure.

Case Scenario: Printed Circuit Board (PCB) Delamination A manufacturer of high-reliability electronics for the aerospace industry is experiencing failures where layers of a multi-layer printed circuit board (PCB) are delaminating (separating) during thermal stress testing. The PCBs are made from layers of fiberglass-epoxy resin.

A failure analyst uses an FTIR microscope with an ATR objective to investigate the delaminated surfaces.

- Reference Spectrum: First, the analyst obtains a reference spectrum from a properly bonded area of a good PCB. This spectrum shows the characteristic peaks of the cured epoxy resin.

- Analysis of Failed Surface: The analyst then examines the surfaces at the point of delamination. The spectrum from one of the surfaces looks significantly different from the reference. It shows that the characteristic peaks indicating a fully cured epoxy are diminished, and a new peak corresponding to a chemical group found in an uncured resin component is present.

- Conclusion: The FTIR evidence strongly suggests that the delamination is occurring because the epoxy resin in that specific layer was not fully cured during the manufacturing process. An incompletely cured resin has poor adhesive properties, leading to the separation of the layers under stress. This chemical insight allows the manufacturing engineers to investigate their curing ovens and process parameters to resolve the issue. Without the molecular-level information provided by FTIR, the root cause of the failure might have remained unknown. This highlights the technique's value in connecting macroscopic failures to their microscopic chemical origins.

The applications in the semiconductor and electronics industry showcase the precision and sensitivity of FTIR spectroscopy. It provides the essential chemical information needed to manufacture complex, reliable devices in an environment where there is no room for error. Laboratories working in this demanding field require top-tier instrumentation, and a careful selection from available advanced FTIR spectrometers is a prerequisite for success.

Application 5: Forensics and Material Conservation

Beyond the industrial production line and the research laboratory, FTIR spectroscopy plays a vital role in fields dedicated to uncovering the past and preserving our cultural heritage. In forensic science, it helps to provide objective chemical evidence that can link a suspect to a crime scene. In the world of art and historical conservation, it allows conservators to understand the materials used by artists and artisans hundreds of years ago, enabling them to make informed decisions about preservation and restoration. In both domains, the non-destructive and highly specific nature of FTIR makes it an invaluable analytical partner.

Analyzing Trace Evidence in Criminal Investigations

Crime scenes are often rich with microscopic traces of evidence—fibers, paint chips, adhesive tapes, or unknown powders. Identifying these materials can be crucial for reconstructing events and establishing links between suspects, victims, and locations. FTIR spectroscopy is a routine method used in forensic labs for the analysis of this type of trace evidence.

- Fibers: A single fiber found on a victim's clothing can be analyzed using an FTIR microscope. The resulting spectrum can identify the fiber's polymer type—is it nylon, polyester, cotton, or wool? If this matches the type of fibers from a carpet in a suspect's car or home, it provides a strong associative link.

- Paint Chips: In a hit-and-run case, a paint chip left at the scene can be analyzed. Automotive paint is a complex multi-layer system, and FTIR can be used to analyze the chemical composition of each layer (primer, basecoat, clearcoat). The resulting spectral profile can be compared to a database of automotive paints to help identify the make, model, and year range of the vehicle involved.

- Adhesive Tapes: The adhesive and backing material of a piece of duct tape used in a crime can be characterized by FTIR. Different brands of tape have unique formulations, and matching the tape from the crime scene to a roll found in a suspect's possession can provide compelling evidence.

- Illicit Drugs: FTIR is used for the rapid identification of seized drugs. An officer can use a portable device to quickly identify a powder as cocaine, heroin, or methamphetamine, providing probable cause for an arrest.

The strength of FTIR in forensics lies in its ability to provide an objective, chemical identification of a material, which is often more robust than a simple visual comparison.

Identifying Pigments and Binders in Artwork

How can we preserve a centuries-old painting for future generations without understanding what it is made of? Art conservators face the challenge of analyzing precious and irreplaceable artworks without causing any damage. FTIR spectroscopy is an ideal tool for this purpose, as it can identify the organic and inorganic materials used by the artist.

Using a non-contact reflection-FTIR setup or by analyzing a microscopic sample taken from an already damaged area, a conservator can identify:

- Pigments: While many historical inorganic pigments (like ochres and lead white) are identified by other techniques, FTIR can identify certain mineral pigments and is excellent at identifying modern synthetic organic pigments.

- Binders: The binder is the medium that holds the pigment particles together and makes them adhere to the canvas or panel. The binder's identity is crucial as it dictates how the paint will age and how it will react to cleaning solvents. FTIR can readily distinguish between different types of binders, such as linseed oil (an oil paint), egg yolk (an egg tempera), or gum arabic (a watercolor).

Case Scenario: The Authentication of a Painting A museum is offered a painting purported to be from the 17th century. Before acquiring it, they must perform a technical analysis to help authenticate it. An art conservator uses FTIR to analyze the pigments and binder. The analysis of a blue passage reveals the pigment is phthalocyanine blue. The FTIR library search is definitive. The problem is that phthalocyanine blue is a synthetic organic pigment that was not invented until the 1930s. Its presence in a painting claimed to be from the 17th century is a clear anachronism. The FTIR analysis, by identifying a material that was not available at the time, provides strong evidence that the painting is a modern forgery.

Assessing Degradation in Historical Artifacts

FTIR is also used to study the chemical degradation of historical materials. By analyzing artifacts made of paper, textiles, leather, or early plastics, conservators can understand the chemical processes of aging. For example, the analysis of an old manuscript might show an increase in carbonyl peaks, indicating oxidation of the cellulose fibers in the paper, which leads to embrittlement. This understanding helps in designing appropriate storage conditions (e.g., low-oxygen environments) and conservation treatments to slow down the rate of decay.

In the case of early plastics from the 20th century, which are now part of museum collections, FTIR is used to identify the polymer type (e.g., cellulose nitrate, cellulose acetate) and to monitor its degradation. Many of these early plastics are inherently unstable and release acidic byproducts as they degrade. FTIR can detect the chemical signs of this degradation, allowing conservators to isolate unstable objects and intervene before they are lost forever. In this way, FTIR spectroscopy serves not just as an analytical tool, but as a guardian of our cultural and historical legacy.

Advanced Data Processing and Spectral Interpretation

Acquiring a high-quality FTIR spectrum is only the first half of the analytical process. The raw data, even after being converted from an interferogram to a spectrum, often requires further mathematical treatment before it can be accurately interpreted. Furthermore, extracting meaningful chemical information from the complex pattern of peaks and troughs requires a combination of systematic knowledge, experience, and the use of powerful software tools. This stage of the process transforms a simple plot into a rich source of chemical insight, allowing the analyst to move from "what is in the spectrum?" to "what does the spectrum tell me about my sample?".

Baseline Correction and Normalization

An ideal FTIR spectrum would have a flat baseline at zero absorbance, with peaks rising from it. In practice, baselines are often sloped, curved, or shifted due to various phenomena like light scattering from particles in the sample (especially in solids), temperature drift in the instrument, or imperfections in the sample itself (e.g., an uneven film). A distorted baseline can interfere with the accurate measurement of peak heights and areas and can foil attempts at spectral subtraction or library searching.

Baseline correction is a routine data processing step used to remedy this. Software algorithms can be used to fit a straight line or a curve to the baseline of the spectrum, which is then subtracted from the entire spectrum to make the baseline flat. The user often needs to select points in the spectrum that are known to be part of the baseline (i.e., regions with no absorption) to guide the algorithm.

Normalization is another common processing step. It involves scaling the spectrum so that its Y-axis falls within a specific range, typically from 0 to 1 absorbance units. This is done by finding the most intense peak in the spectrum, setting its absorbance to 1, and scaling all other data points proportionally. Normalization is useful when comparing the shapes and peak positions of different spectra without being distracted by differences in their overall intensity (which can be due to variations in sample concentration or pathlength). It is a standard procedure before performing a library search.

Library Searching and Compound Identification

For identifying an unknown compound, the most powerful tool available to the FTIR user is the spectral library search. A spectral library is a large digital database containing thousands or even hundreds of thousands of reference FTIR spectra of known pure compounds.

After collecting and processing the spectrum of an unknown sample, the user can instruct the software to search this spectrum against the library. The software uses a correlation algorithm to compare the unknown spectrum with every entry in the library, calculating a "Hit Quality Index" (HQI) or match score for each comparison. The algorithm considers peak positions, relative intensities, and peak shapes.

The software then presents a "hit list" of the best matches, ranked from highest to lowest HQI. A high-quality match (e.g., an HQI > 900 out of 1000) between the unknown and a library standard provides a strong indication of the unknown's identity. However, it is crucial for the analyst to visually inspect the unknown spectrum overlaid with the best-match library spectrum. A good match should show alignment of all major peaks. The analyst must use their chemical knowledge to confirm that the proposed identification makes sense in the context of the sample's origin. For example, if the best match for a "white powder" is the polymer Teflon, but the sample is soluble in water, the identification is clearly incorrect, and lower-ranked hits should be examined.

Understanding Spectral Artifacts and Apodization

The process of converting an interferogram into a spectrum is not without its own set of potential pitfalls. One issue arises from the fact that an interferogram must be truncated; the moving mirror can only scan a finite distance. This sudden truncation of the signal is like abruptly cutting off a sound wave. The Fourier transform of this truncated signal results in spectral artifacts, specifically "side-lobes" or "ringing" that appear as small, oscillating ripples on either side of a sharp absorption peak. These can be mistaken for real, small peaks.

To mitigate this, a process called apodization is used. Before performing the Fourier transform, the interferogram is multiplied by a mathematical weighting function, known as an apodization function. These functions (with names like Triangle, Hanning, or Beer-Norton) smoothly taper the intensity of the interferogram down to zero at its ends, avoiding the abrupt truncation. This process effectively suppresses the side-lobes in the resulting spectrum. However, there is a trade-off: apodization invariably causes a slight broadening of the spectral peaks, which means a small reduction in the effective resolution. The choice of apodization function allows the user to balance the need for low noise and clean baselines against the need for high resolution. For most analytical work, a mild apodization function is used as a good compromise. Understanding these data processing steps is essential for any serious user of FTIR spectroscopy, as it allows for the generation of clean, reliable, and interpretable data from the raw instrument output.

Frequently Asked Questions (FAQ)

What is FTIR spectroscopy primarily used for? FTIR spectroscopy is primarily used for the identification and characterization of chemical substances. Its main application is to determine the molecular structure of a sample by identifying the functional groups present. This makes it an invaluable tool for quality control to verify the identity of raw materials and finished products, for research and development to characterize new compounds, and for failure analysis to identify contaminants or degradation products. It is widely applied across industries including pharmaceuticals, polymers, chemicals, environmental science, and forensics.

What is the difference between FTIR and IR spectroscopy? The terms are often used interchangeably, but there is a key instrumental difference. "IR spectroscopy" is a general term for the study of the interaction of infrared light with matter. Older, traditional IR instruments were of a "dispersive" type, using a prism or grating to separate the light into individual frequencies and measure them one by one. "FTIR spectroscopy" refers to a more modern method where all infrared frequencies are measured simultaneously using an interferometer. The data is collected as an interferogram and then a Fourier Transform (FT) is applied to get the spectrum. FTIR instruments are much faster, more sensitive, and have better accuracy than older dispersive instruments, which is why they have become the standard.

What kinds of materials can FTIR not analyze? FTIR spectroscopy relies on the absorption of infrared light by vibrating chemical bonds. Therefore, it cannot analyze materials that do not have chemical bonds that are infrared active. This includes individual atoms (like noble gases such as argon or helium) and simple monatomic ions (like Na⁺ or Cl⁻ in a salt crystal). Also, homonuclear diatomic molecules like nitrogen (N₂), oxygen (O₂), and chlorine (Cl₂) do not absorb infrared radiation because their vibration does not cause a change in the molecule's dipole moment, which is a requirement for IR absorption. Lastly, materials that are completely opaque to infrared light, such as most metals, cannot be analyzed directly by transmission FTIR.

How do you prepare a sample for FTIR analysis? Sample preparation depends heavily on the physical form of the sample and the chosen measurement technique. For the highly popular ATR-FTIR method, sample preparation is minimal; a solid or liquid is simply placed on the ATR crystal and pressure is applied. For traditional transmission analysis, liquids can be placed as a thin film between two salt plates. Solid powders are often ground with KBr powder and pressed into a thin, transparent pellet. Thin polymer films can often be analyzed directly. Gases require a special gas cell with a long pathlength. The goal is always to have the right amount of sample in the beam to get a good quality spectrum without the peaks being totally absorbed.

Is FTIR a destructive or non-destructive technique? FTIR spectroscopy is generally considered a non-destructive technique. In most cases, particularly when using ATR or reflection methods, the sample can be recovered completely unaltered after the analysis. The infrared light used is of low energy and does not cause chemical changes to the sample. The only instance where the sample might be "destroyed" or altered is during certain transmission sample preparation methods, such as when a sample is dissolved in a solvent or irretrievably mixed and ground with KBr to form a pellet.

What is the difference between FTIR and Raman spectroscopy? FTIR and Raman are both forms of vibrational spectroscopy that provide information about a molecule's structure, and they are often considered complementary. The main difference lies in the physical principles. FTIR measures the direct absorption of infrared light. Raman spectroscopy, on the other hand, involves a light scattering process. A sample is illuminated with a high-intensity monochromatic laser (usually in the visible or near-infrared range), and the instrument analyzes the light that is scattered from the sample. While most of the light is scattered at the same frequency as the laser (Rayleigh scattering), a tiny fraction is scattered at different frequencies (Raman scattering). The frequency shifts are related to the vibrational modes of the molecule. A key difference in selection rules means that some vibrations that are strong in Raman are weak or absent in FTIR, and vice versa. For example, symmetric bonds like C-C in a diamond or S-S are very strong in Raman but invisible in FTIR. Water is a very strong absorber in FTIR, often obscuring other peaks, but it is a very weak Raman scatterer, making Raman an excellent choice for analyzing samples in aqueous solutions.

What does the "fingerprint region" in an FTIR spectrum mean? The fingerprint region is the lower-frequency portion of the mid-infrared spectrum, typically from about 1500 cm⁻¹ down to 400 cm⁻¹. This region is particularly rich in information. While the higher-frequency region (4000-1500 cm⁻¹) is often dominated by a few strong peaks from specific stretching vibrations (like O-H, N-H, C-H, C=O), the fingerprint region contains a complex pattern of many overlapping peaks that arise from a combination of bending vibrations and other skeletal vibrations involving larger parts of the molecule. This complex pattern is unique to a particular molecule, much like a human fingerprint is unique to an individual. Even very similar molecules, like isomers, will show distinct differences in their fingerprint regions. Therefore, this region is extremely useful for confirming the identity of a compound by matching it against a known standard.

Conclusion

The journey through the principles and applications of Fourier Transform Infrared spectroscopy reveals a technique of remarkable depth and versatility. We have seen how it translates the silent, invisible dance of molecular vibrations into a rich, informative spectrum—a unique fingerprint for nearly every chemical substance. From the elegant mechanics of the Michelson interferometer to the mathematical power of the Fourier transform, the method is a triumph of physics and computation applied to the world of chemistry.

The choice of sampling technique—whether the classic bulk analysis of transmission, the convenient surface probing of ATR, or the specialized approaches of reflection—allows the analyst to tailor the experiment to the specific question at hand. This flexibility is what enables FTIR to serve as a cornerstone analytical tool across an astonishingly broad range of disciplines. In the pharmaceutical industry, it stands as a vigilant guardian of quality and safety. For polymer scientists, it is the key to understanding material structure and performance. For environmental watchdogs, it is an essential instrument for monitoring the health of our planet. In the microscopic world of electronics and the macroscopic worlds of forensics and art conservation, FTIR provides the chemical clues that solve complex problems. Ultimately, understanding FTIR spectroscopy is not just about learning a technique; it is about learning a new language to communicate with the molecular world, a language that speaks of structure, identity, and transformation.

References

Bruker. (2025). A comprehensive guide to photothermal AFM-IR spectroscopy. Bruker Corporation. Retrieved from

Covalent Metrology. (2025). Fourier transformed infrared spectroscopy (FTIR). Retrieved from https://covalentmetrology.com/service/fourier-transformed-infrared-spectroscopy-ftir/

Infinita Lab. (2021). Fourier transform infrared spectroscopy – FTIR. Retrieved from https://infinitalab.com/metrology-testing-service/fourier-transform-infrared-spectroscopy-ftir/

Interspectrum. (2020). Compact FTIR spectrometer Interspec 650-X. Retrieved from

Newport Corporation. (2025). Introduction to FTIR spectroscopy. Retrieved from

Newport Corporation. (2025). FT-IR spectroscopy definitions of characteristics. Retrieved from https://www.newport.com/n/ft-ir-spectroscopy-definitions-of-characteristics

Shimadzu Scientific Instruments. (2024). IRTracer-100 FTIR spectrophotometer – Specs. Retrieved from