Manual Hot Press Hydraulic Machine Large Panel YPH-800D

Overview

The YPH‑800D is a robust hot press hydraulic machine designed for large panels and industrial-scale lab operations. It combines manual hydraulic control with advanced heating to provide precise, consistent pressure across broad surfaces.

Key Features of Manual Hot Press Hydraulic Machine

- Control pressure and temperature:0.1T/0.1°C(Customizable accuracy)

- Dwell time:Unlimited time (manual pressure relief)

- Display usage:7 inch LCD touch screen/English interface can be switched

- Die pressure conversion:PCB control program automatically converts to display sample pressure (Mpa)

- Heating plate type:Four-column positioning thermal insulation design, upper plate screw suspension design/electroplated polished panel

- Heating core material:Aluminum heating core

- Heat insulation method:Imported mica heat insulation board

- Security configuration:Mold temperature exceeds 50'C, temperature controller prompts "Pay attention to anti-hot"

- Temperature die:5 stages adjustable continuous temperature control - automatic heating - automatic insulation - natural cooling

Applications

Ideal for pressing large polymer, rubber, composite, or layered panels in laboratory or industrial environments. Its reliability and precision reflect the quality standards of professional hydraulic press machines.

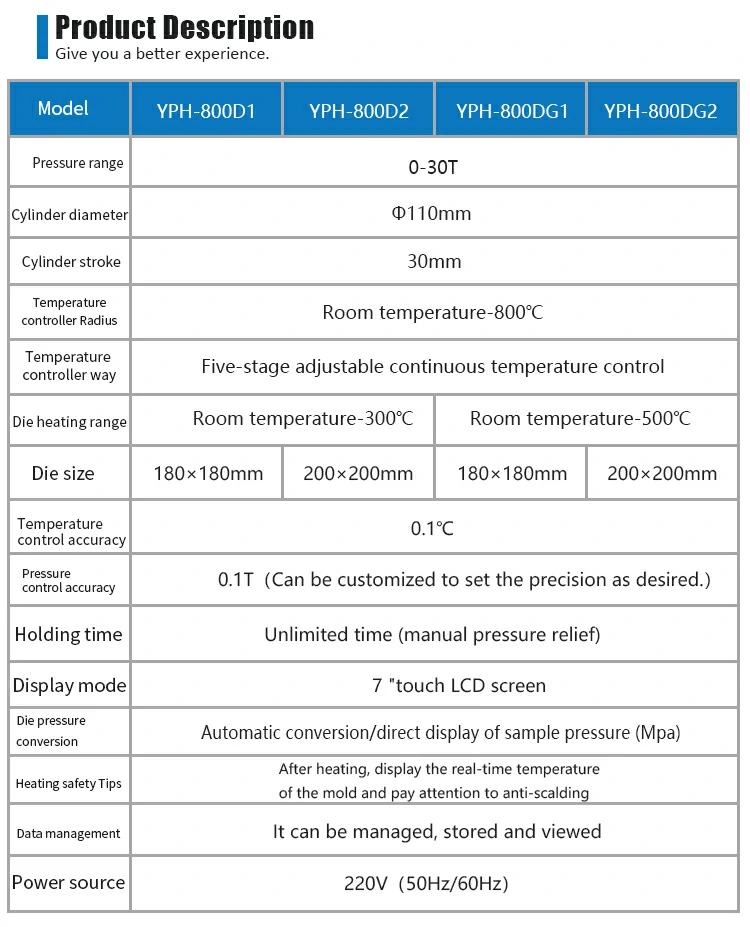

Product Description

| Model | YPH-800D1 | YPH-800D2 | YPH-800DG1 | YPH-800DG2 |

| Pressure range | 0-30T | |||

| Cylinder diameter | Φ110mm | |||

| Cylinder stroke | 30mm | |||

| Temperature controller Radius | Room temperature-800∘C | |||

| Temperature controller way | Five-stage adjustable continuous temperature control | |||

| Die heating range | Room temperature-300∘C | Room temperature-500∘C | ||

| Die size | 180x180mm | 200x200mm | 180x180mm | 200x200mm |

| Temperature control accuracy | 0.1∘C | |||

| Pressure control accuracy | 0.1T (Can be customized to set the precision as desired.) | |||

| Holding time | Unlimited time (manual pressure relief) | |||

| Display mode | 7 "touch LCD screen | |||

| Die pressure conversion | Automatic conversion/direct display of sample pressure (Mpa) | |||

| Heating safety Tips | After heating, display the real-time temperature of the mold and pay attention to anti-scalding | |||

| Data management | It can be managed, stored and viewed | |||

| Power source | 220V (50Hz/60Hz) | |||

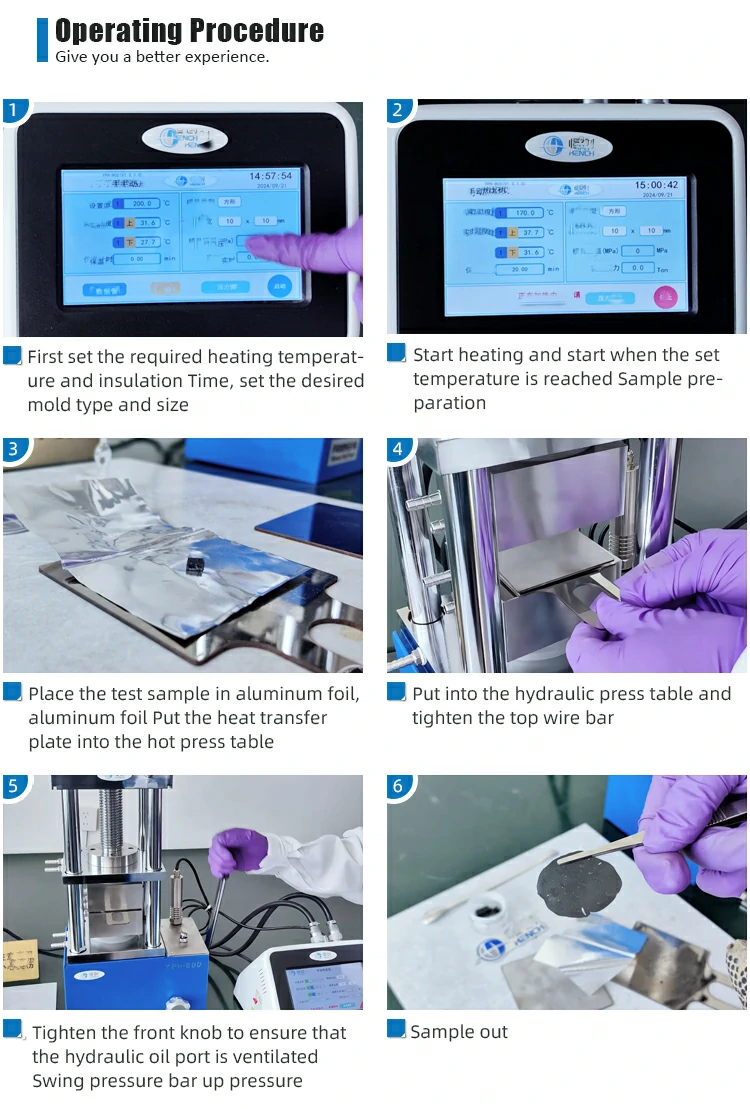

Operating Procedure

-

First, set the required heating temperature and insulation time, as well as the desired mold type and size.

-

Start heating, and begin sample preparation once the set temperature is reached.

-

Place the test sample in aluminum foil, then place the aluminum foil with the heat transfer plate onto the hot press table.

-

Insert it into the hydraulic press table and tighten the top screw bar.

-

Tighten the front knob to ensure the hydraulic oil port is ventilated, then swing the pressure bar upward to apply pressure.

-

Remove the prepared sample.

Why Hench?

Hench Technology Co., Ltd., based in Tianjin, China, is a leading hydraulic press manufacturer, producing high-quality hydraulic and heated presses for lab and industrial applications. Hench machines are designed for durability, safety, and ease of use, serving research institutes, universities, and industrial clients worldwide. Their expertise ensures consistent performance, professional support, and customizable solutions for complex pressing tasks.