Special Shaped Dies

Discover precision-engineered pellet press die set and advanced special shaped dies for custom applications. Contact us today for tailored solutions.

-

ZnSe Window Zinc Selenide Window Sheet

Bulk absorption coefficient:10.6 Mm 0.0005/cm

Refractive index temperature change rate:10.6 lm 61x10-6/°C

Refractive index inhomogeneity:632.8nm<6x10-6

Pyrocondu ctivity:0.18w/cm/°c

Specific heat:0.356J/g/c

linear expansion coefficient:20℃:7.57x10-6/°C

-

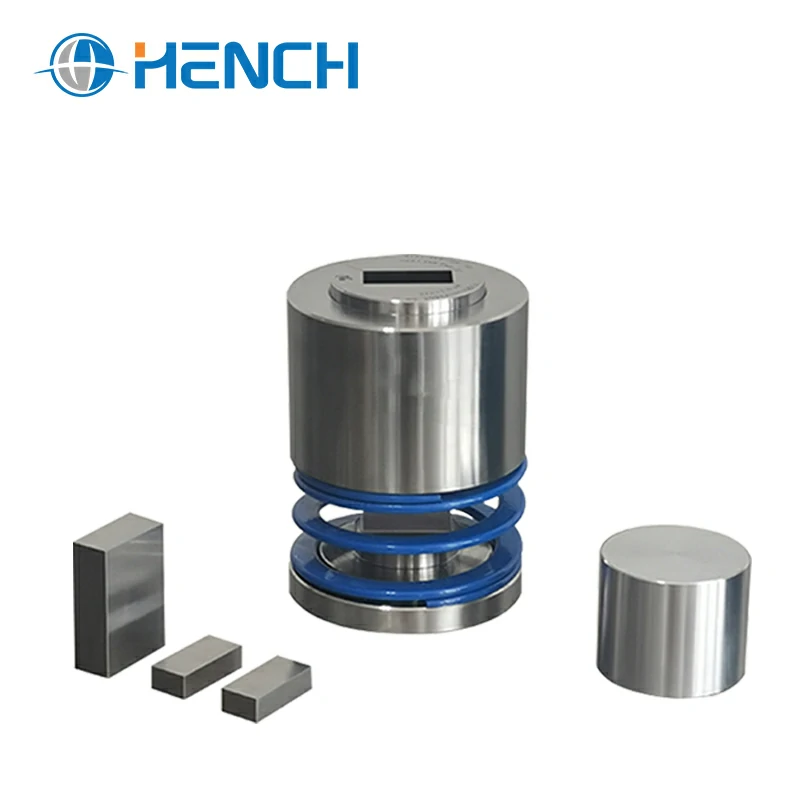

Square bidirectional pressurizing die 3-20mm HMT

Model:HMS

Mold material:9Cr18

Indenter hardness:HRC58

Sample size:3-20mm

Cavity depth:40mm

Boundary dimension:88 X175mm

Die weight:3.0Kg

-

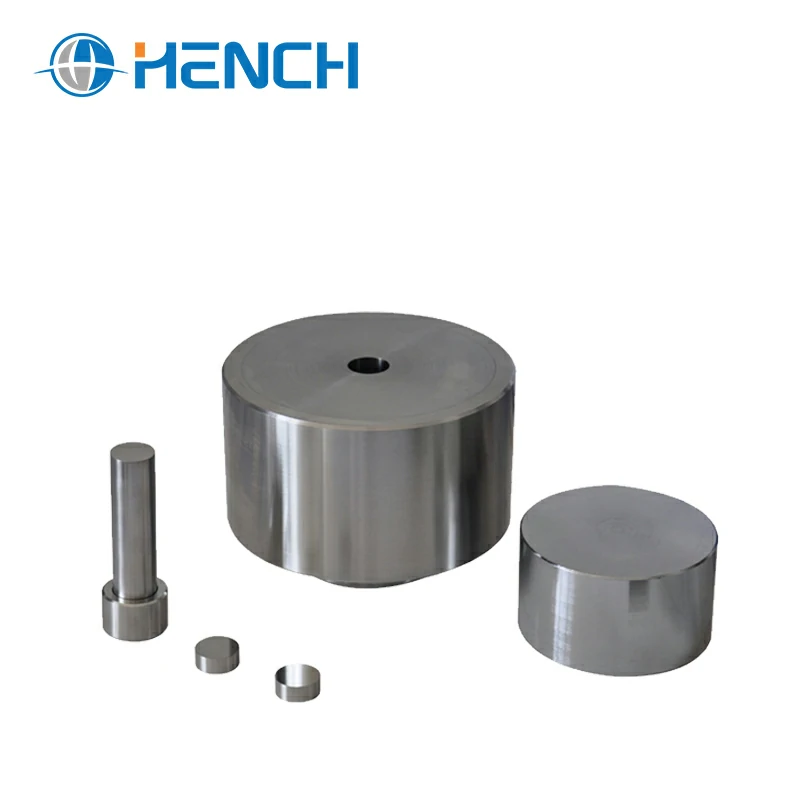

Circular bidirectional pressurizing die 3-20mm HMS

Model:HMS

Mold material:9Cr18

Indenter hardness:HRC58

Sample size:3-20mm

Cavity depth:40mm

Boundary dimension:88 X175mm

Die weight:3.0Kg

-

Anti-cracking die 3-20mm HML

Model:HML

Mold material:9Cr18

Indenterhardness:HRC58

Sample size:3-20mm

Cavity depth:40mm

Boundary dimension:98 X120mm

Die weight:5Kg

-

Spherical Tablet Die 2-60mm HMQ

Model:HMQ

Mold material:9Cr18

Indenter hardness:HRC58

Sample size:2-60mm

Cavity depth:40/60mm

Boundary dimension:53 x120mm/80 x150mm

Die weight:1.4Kg/5.8Kg

-

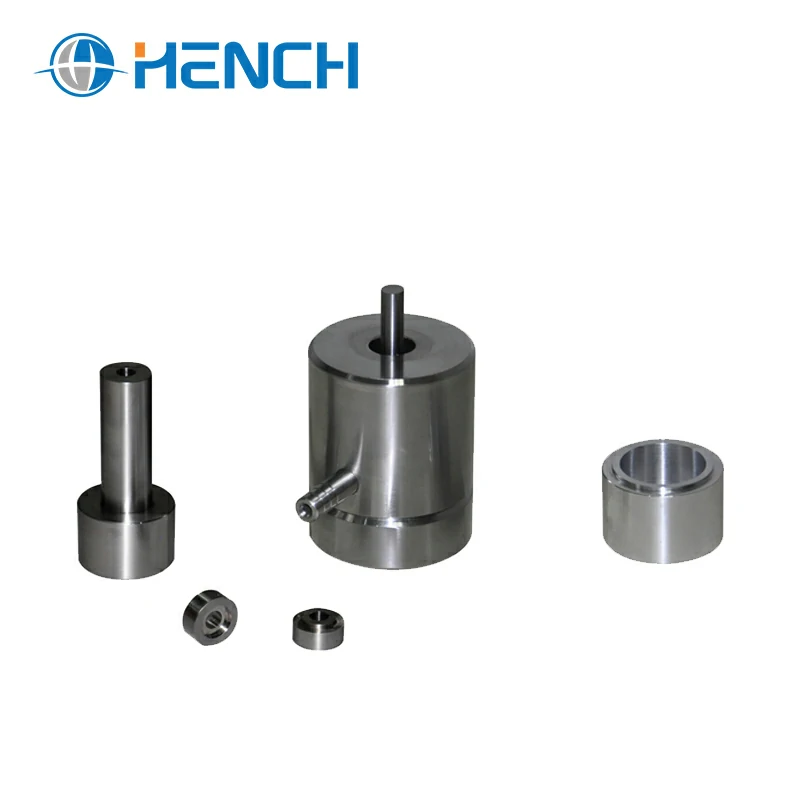

Ring-shaped Tablet Press 3-90mm HMO

Model:HMO

Mold material:9Cr18Indenterhardness:HRC58

Sample size:3-90mm

Cavity depth:40mm/45mm

Boundary dimension:53 x120mm/72 x100mm/88 x120mm

Die weight:1.4Kg/3.5Kg/5Kg

Advanced Special Shaped Dies for Custom Applications

Our special shaped dies are designed to handle complex profiles and non-standard geometries with exceptional precision. Made with high-quality materials and advanced processing technology, these dies ensure durability, smooth performance, and accurate shaping across various industrial and laboratory applications. Whether you need custom cross-sections or specialized die tooling, we provide reliable solutions tailored to your needs.

Precision, Durability, and Versatility

Engineered for both research and industrial use, our special shaped dies deliver consistent results and long service life. Their superior design supports high wear resistance, excellent heat tolerance, and precise material flow, making them the perfect choice for industries requiring complex die profiles. By combining innovation with strict quality control, we ensure optimal efficiency in every application.

Why Choose Hench – Trusted Manufacturer

At Hench, we are more than just a die supplier. As one of the leading lab supplies manufacturers, we integrate advanced technology, strict testing, and decades of expertise to deliver premium-quality dies. Our team is committed to providing customized solutions that meet the highest standards of accuracy and durability, ensuring long-term value and customer satisfaction.