Pellet Molding Die Series

Discover our premium pellet die series, designed for precision and durability in pellet molding. Optimize your production and achieve consistent results. For inquiries or custom solutions, Contact us today!

-

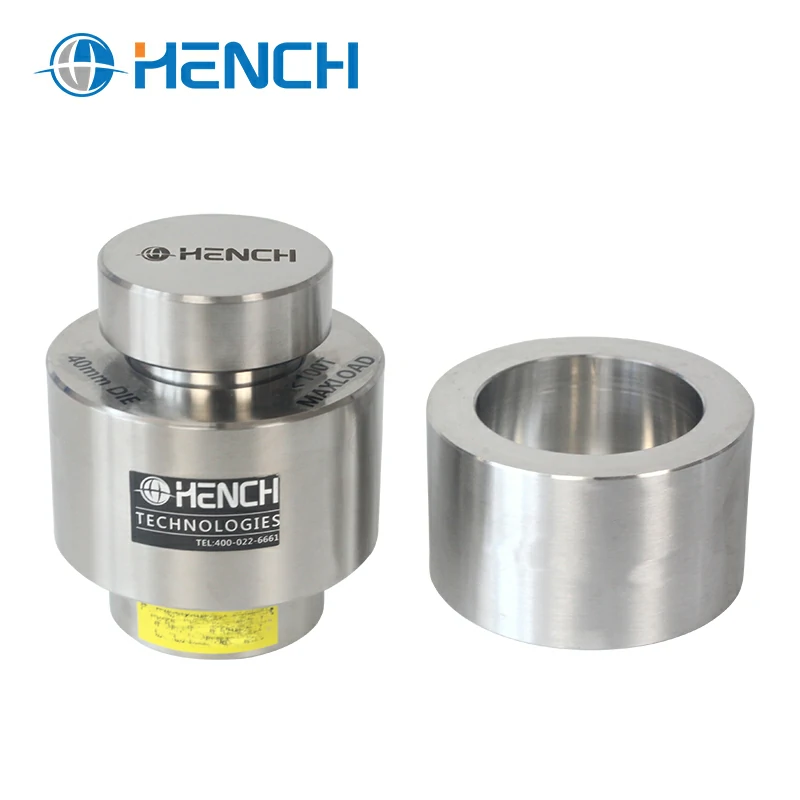

Round Sample Dies 41-80mm HMY

Model:HMY

Sample size:41.0-50.9mm/51-60mm/61-70mm/71-80mm

Die material:9Cr18

Indentation hardness:HRC58

Cavity depth:55mm/60mm/65mm/70mm

Size:88x150mm/98x180mm/108x180mm/118 x150mm

Weight:5.1Kg/7.3Kg/9Kg/11.5Kg

-

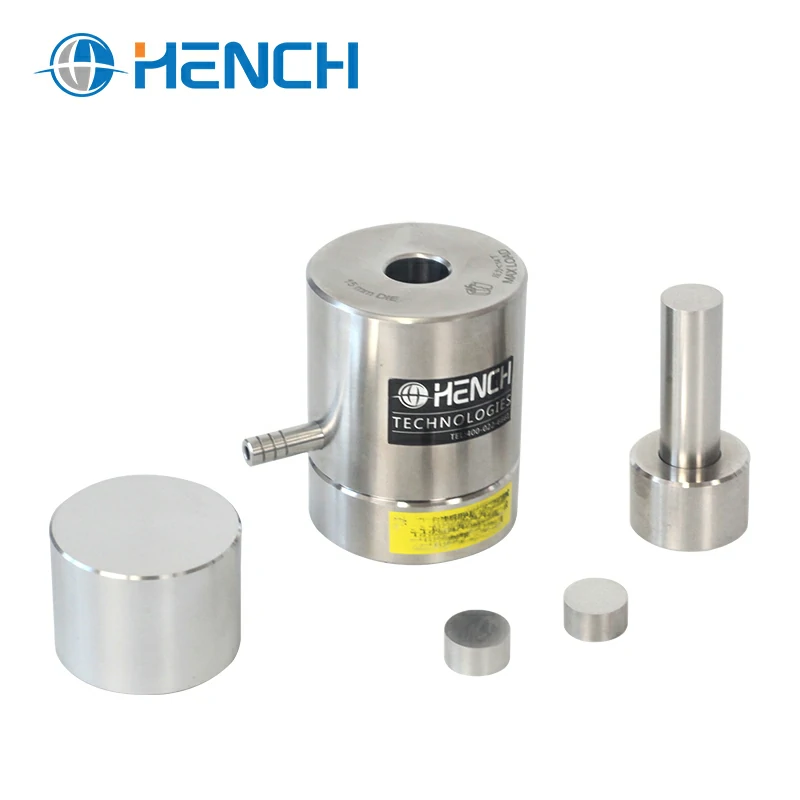

Circular Tablet Press Die 2.0-40.9mm HMY

Model:HMY

Sample size:2.0-6.0mm/6.1-14.9mm/15.0-25.9mm/26.0-40.9mm

Dies material:9Cr18

Indentationhardness:HRC58

Cavity depth:20mm/30mm/40mm/45mm

Size:43x78mm/43x93mm/53x120mm/73 x133mm

Weight:0.55Kg/0.67Kg/1.34Kg/2.9Kg

High-Performance Pellet Machine Die for Reliable Production

Our pellet machine die series ensures accurate pellet formation and long-lasting performance. Designed for industrial and laboratory use, these dies guarantee uniform size and density, reducing material waste and improving productivity. For specialized applications, explore our Cylindrical Dies, Fluorescent borate dies, and Sintered-carbide dies to meet diverse processing needs.

Durable Pellet Press Die Solutions for Optimal Sample Preparation

Our pellet press die are engineered for precision and resilience. Each pellet press die set is crafted from high-quality materials to withstand repeated use under high pressure. Ideal for tablet pressing, powder compaction, and sample preparation, these dies enhance efficiency while maintaining consistent quality for laboratory and industrial applications.

About Hench Technology

Hench Technology has over 30 years of expertise in precision die manufacturing, serving industries worldwide. As a trusted provider of pellet dies, we focus on innovation, quality, and customer satisfaction. Our dedicated team ensures every die meets strict standards, offering reliable solutions for laboratories and industrial pellet molding projects. Learn more about our company on Hench Technology.

.png)

.png)