NDM-15 15-ton Laboratory IR Press

Laboratory IR Press Feature

The NDM-15 infrared pressing machine adopts an integrated structure, with a fast upper pressing speed and no oil leakage.

It is suitable for pressing powder samples for infrared spectrometers. The use of imported plungers further improves the stability of the product. It can be equipped with 7mm and 13mm infrared pressing molds. This product can be compatible with all brands of Fourier transform infrared spectrometers, such as: Beidian Rui Li, Tianjin. Hongdong, Thermo from the United States, PE from the United States, Bruker from Germany, Shimadzu from Japan, etc.

Versatile Compatibility with FTIR Spectrometers

This infrared pressing machine is compatible with all major FTIR spectrometer brands, including Beidian Rui Li, Tianjin Hongdong, Thermo (USA), PE (USA), Bruker (Germany), and Shimadzu (Japan). It can be equipped with 7 mm and 13 mm infrared pressing molds, making it a versatile choice for various laboratory applications.

Compact Design with Enhanced Stability

The NDM-15 features a compact design with dimensions of 196 × 260 × 380 mm and weighs 17.8 kg, making it suitable for laboratory environments with limited space. The use of imported plungers further improves the stability and reliability of the press.

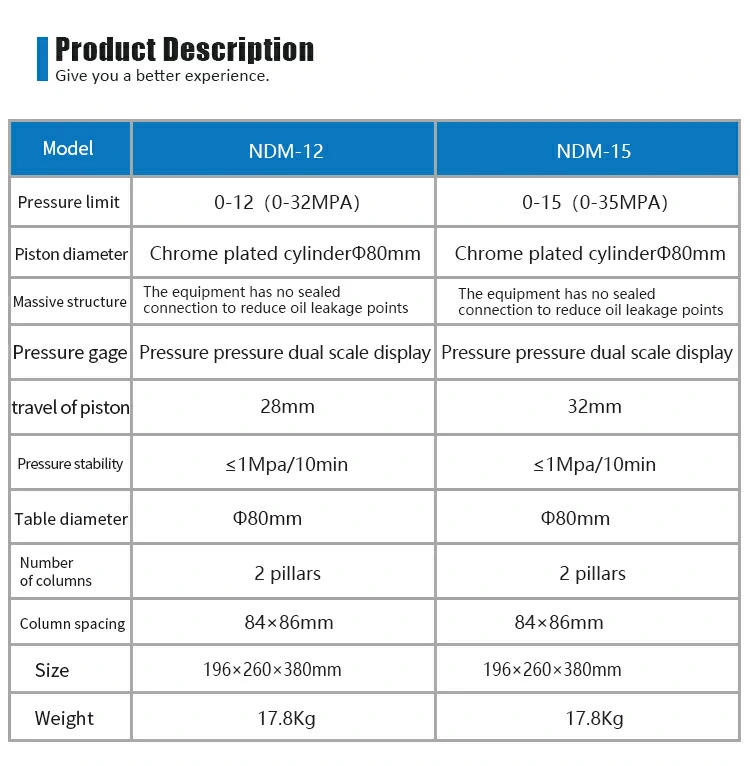

Product Description

| Item | NDM-12 | NDM-15 |

|---|---|---|

| Pressure limit | 0-12 (0-32MPA) | 0-15 (0-35MPA) |

| Piston diameter | Chrome plated cylinder Φ80mm | Chrome plated cylinder Φ80mm |

| Massive structure | The equipment has no sealed connection to reduce oil leakage points | The equipment has no sealed connection to reduce oil leakage points |

| Pressure gage | Pressure pressure dual scale display | Pressure pressure dual scale display |

| Travel of piston | 28mm | 32mm |

| Pressure stability | ≤1MPa/10min | ≤1MPa/10min |

| Table diameter | Φ80mm | Φ80mm |

| Number of columns | 2 pillars | 2 pillars |

| Column spacing | 84×86mm | 84×86mm |

| Size | 196×260×380mm | 196×260×380mm |

| Weight | 17.8kg | 17.8kg |

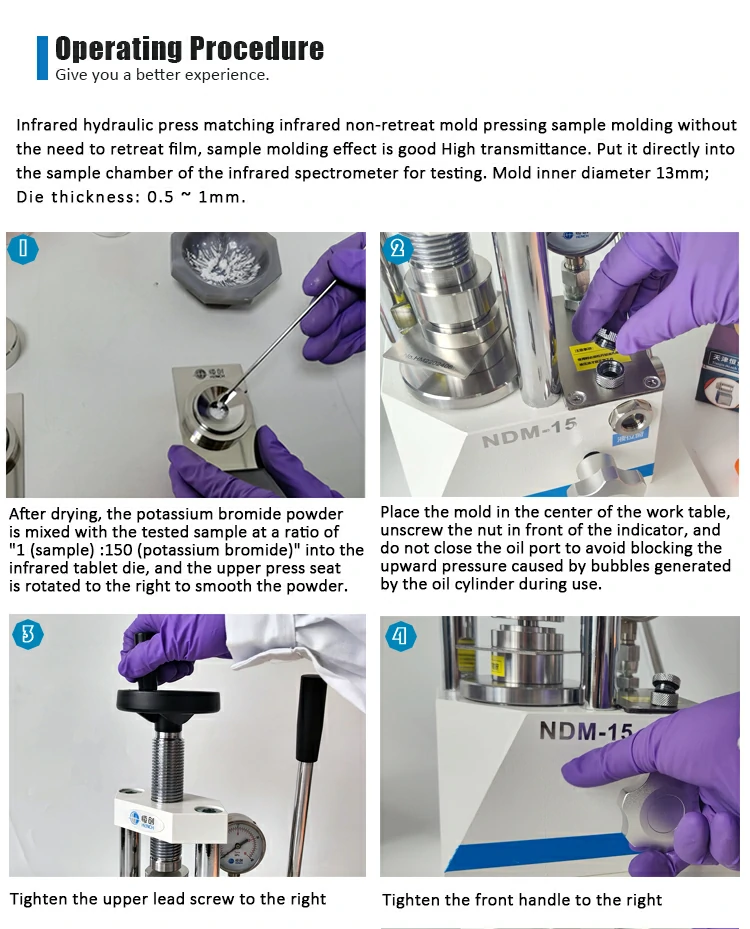

Operating Procedure

An infrared hydraulic press with an infrared non-retractable mold allows sample molding without the need to remove the film. The molding effect is good, with high transmittance, and the sample can be directly placed into the sample chamber of the infrared spectrometer for testing. Mold inner diameter: 13 mm; Die thickness: 0.5–1 mm.

-

After drying, mix the potassium bromide powder with the sample to be tested at a ratio of 1 (sample) : 150 (potassium bromide) in the infrared tablet die. Rotate the upper press seat to the right to smooth the powder.

-

Place the mold in the center of the work table. Unscrew the nut in front of the indicator, and keep the oil port open to avoid blocking the upward pressure caused by bubbles generated in the oil cylinder during use.

-

Tighten the upper lead screw to the right.

-

Tighten the front handle to the right.

-

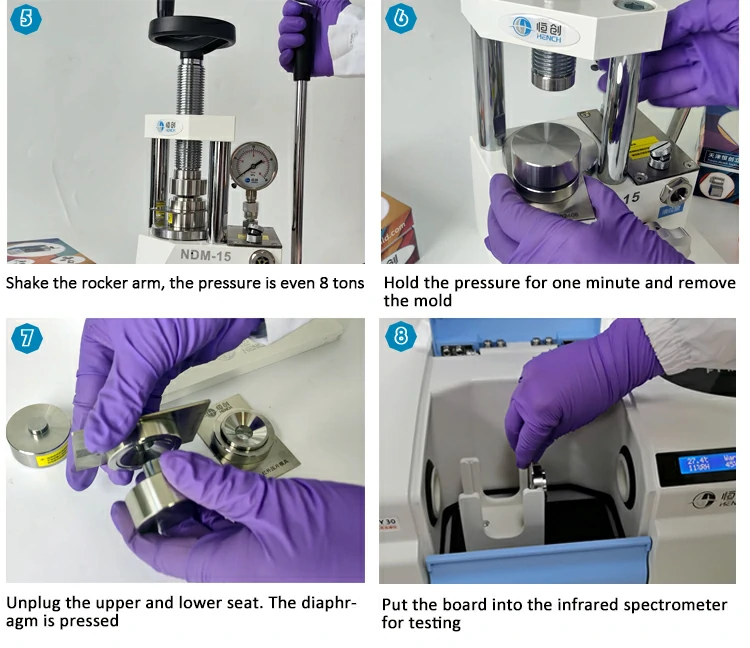

Shake the rocker arm until the pressure reaches 8 tons.

-

Hold the pressure for one minute, then remove the mold.

-

Unplug the upper and lower seats. The diaphragm is pressed.

-

Place the pressed tablet into the infrared spectrometer for testing.

About Hench Technology

Hench Technology Co., Ltd., located in Tianjin, China, specializes in designing and manufacturing accessories and equipment for infrared spectroscopy sample preparation. With strong in-house R&D, precision manufacturing, and thorough quality control, Hench produces dies, molds, presses, and full accessory lines. As a respected hydraulic press supplier, we ensure high performance, durability, and reliable customer support.