laboratory presses

Discover Hench Technology’s range of precision laboratory presses, designed for efficient sample preparation and reliable performance. For inquiries or quotes, contact us today.

-

2/10/20/30/40/60-ton Fully Automatic Powder Tablet Press Machine HAP-S

Fully Automatic Powder Tablet Press Machine

The HAP series automatic hydraulic press with hydraulic drive is mainly used for powder molding sample preparation and is widely applied in X-ray fluorescence, calcium and iron analysis, superconductivity, building materials, ceramics, cement, and other material field research. This product provides precise control to solve the problem of the 6 mm die under the automatic pellet press, and it also meets customers’ multi-stage pressure requirements while incorporating numerous safety features.

Key Features

Advanced Hydraulic Press Technology

At the core of the HAP-30S is its hydraulic press system, which provides uniform pressure distribution across the die, ensuring high-density tablets with minimal variation. This technology is a testament to Hench's commitment to quality and innovation in laboratory equipment. For a broader range of hydraulic solutions, explore our Hydraulic Press Series.

Tailored for Laboratory Excellence

The HAP-30S is meticulously crafted to meet the rigorous demands of laboratory environments. Its compact design, combined with advanced features, makes it an indispensable tool for researchers and technicians seeking reliability and precision. Discover more about our comprehensive lab supplies to enhance your laboratory's capabilities.

Intelligent Control and Safety Features

Equipped with the Savta intelligent program control system, the HAP-30S allows for up to 15 programmable pressure stages, offering flexibility for various sample types. Safety is paramount; the machine includes a 7" touch LCD screen, emergency stop functions, and overpressure protection mechanisms. For those interested in automated solutions, our Automatic Hydraulic Press category provides a range of options to suit diverse needs.

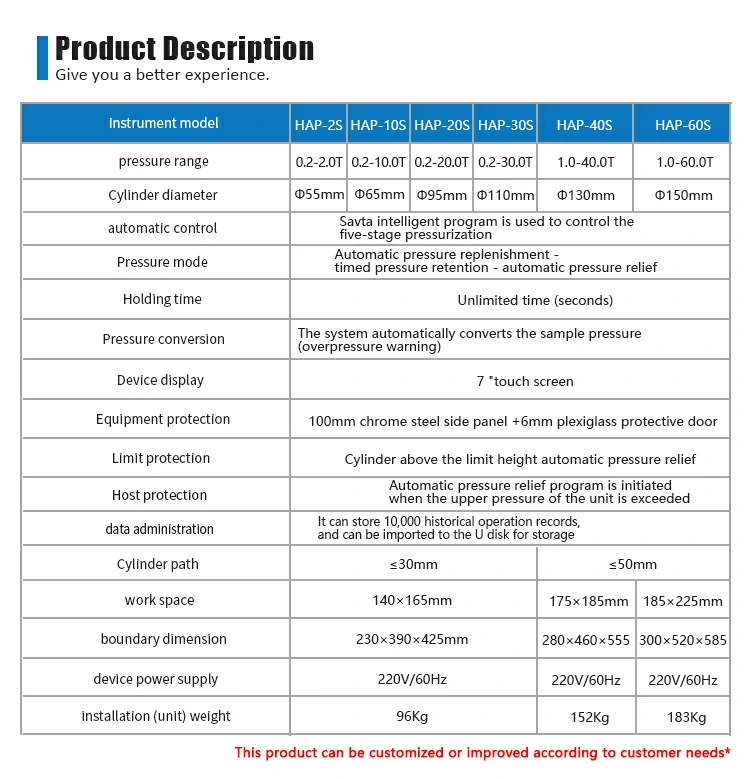

Product Description

Instrument model HAP-2S HAP-10S HAP-20S HAP-30S HAP-40S HAP-60S pressure range 0.2-2.0T 0.2-10.0T 0.2-20.0T 0.2-30.0T 1.0-40.0T 1.0-60.0T Cylinder diameter Φ55mm Φ65mm Φ95mm Φ110mm Φ130mm Φ150mm automatic control Savta intelligent program is used to control the five-stage pressurization Pressure mode Automatic pressure replenishment - timed pressure retention - automatic pressure relief. Holding time Unlimited time (seconds) Pressure conversion The system automatically converts the sample pressure (overpressure warning) Device display 7* touch screen Equipment protection 100mm chrome steel side panel + 6mm plexiglass protective door Limit protection Cylinder above the limit height automatic pressure relief Host protection Automatic pressure relief program is initiated when the upper pressure of the unit is exceeded data administration It can store 10,000 historical operation records, and can be imported to the U disk for storage Cylinder path ≤30mm ≤50mm work space 140×165mm 175×185mm 185×225mm boundary dimension 230×390×425mm 280×460×555mm 300×520×585mm device power supply 220V/60Hz 220V/60Hz 220V/60Hz Installation (unit) weight 96Kg 152Kg 183Kg This product can be customized or improved according to customer needs*

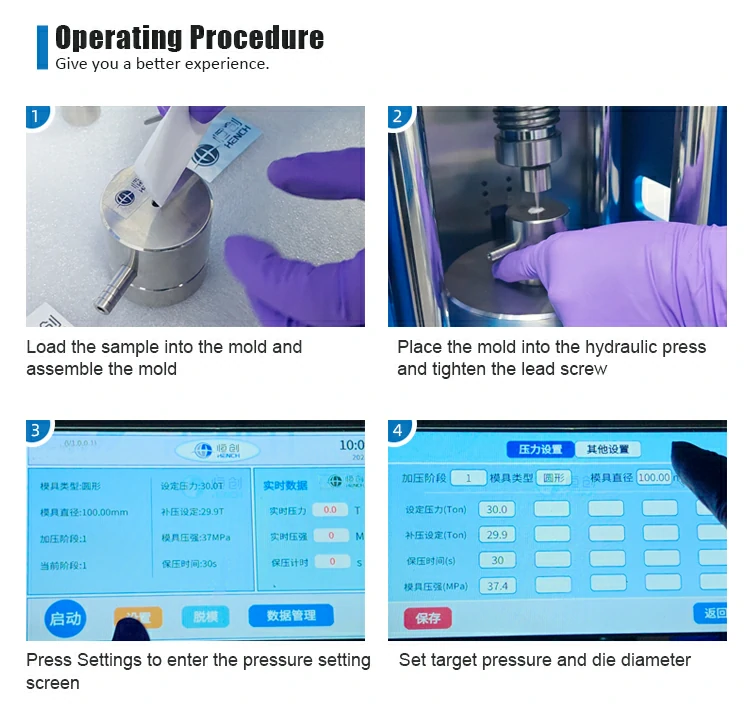

Operating Procedure

-

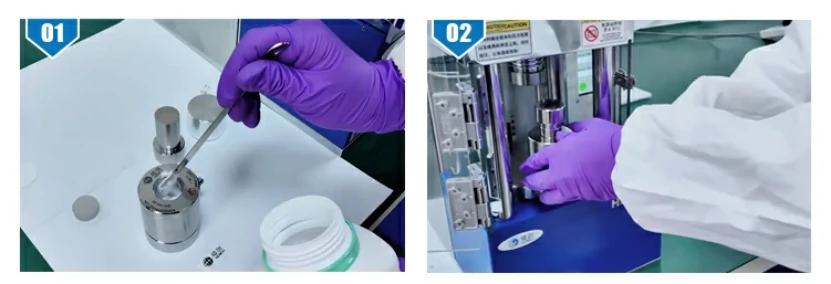

Load the sample into the mold and assemble the mold.

-

Place the mold into the hydraulic press and tighten the lead screw.

-

Press Setting to enter the pressure setting screen.

-

Set the target pressure and die diameter.

-

Return to the home screen and press Start to increase the pressure.

-

After reaching the set pressure, the system automatically maintains pressure and then automatically relieves pressure.

-

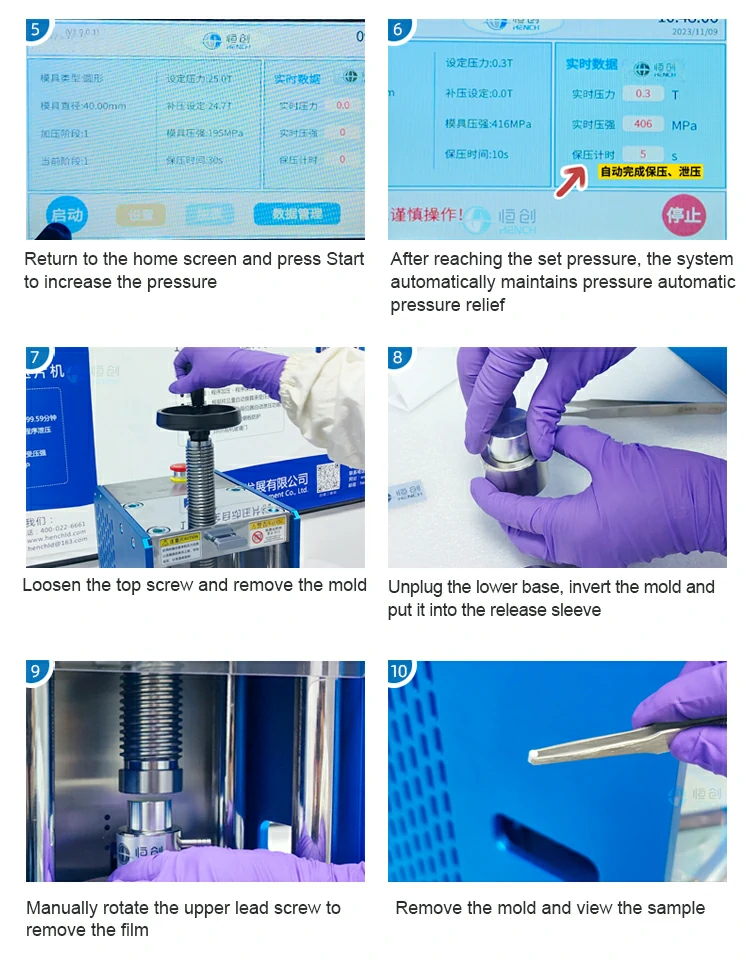

Loosen the top screw and remove the mold.

-

Unplug the lower base, invert the mold, and place it into the release sleeve.

-

Manually rotate the upper lead screw to remove the film.

-

Remove the mold and check the sample.

Detail Description

-

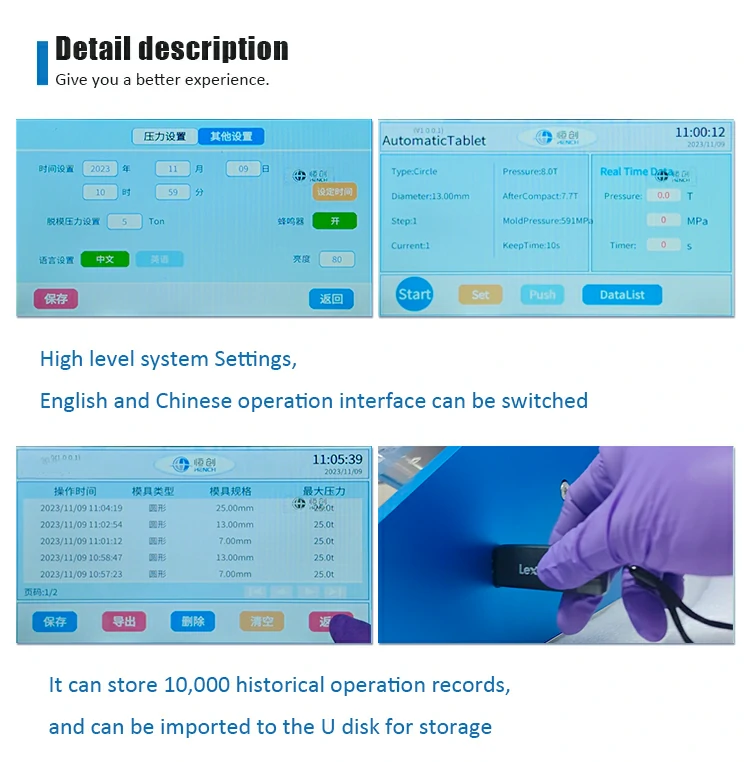

High-level system settings, with switchable English and Chinese operation interfaces.

-

Capable of storing 10,000 historical operation records, which can be exported to a USB disk for storage.

Operation Interface

-

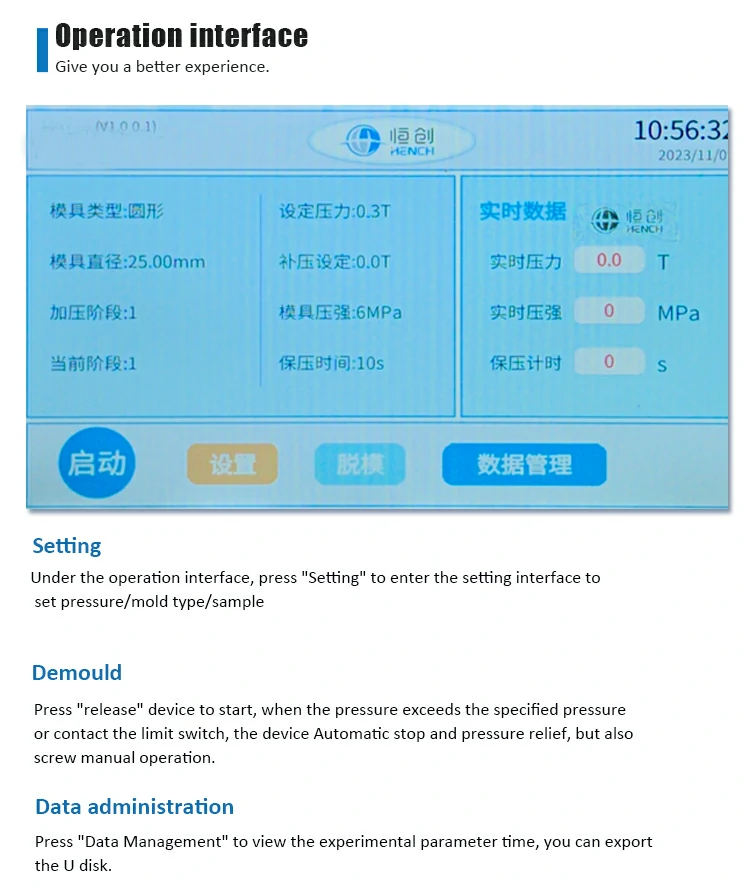

Setting

Under the operation interface, press Setting to enter the setting interface. Here you can set pressure, mold type, and sample parameters. -

Demould

Press the Release button to start. When the pressure exceeds the specified value or the limit switch is triggered, the device will automatically stop and relieve pressure. Manual screw operation is also available. -

Data Administration

Press Data Management to view experimental parameters and time records. Data can be exported to a USB disk. -

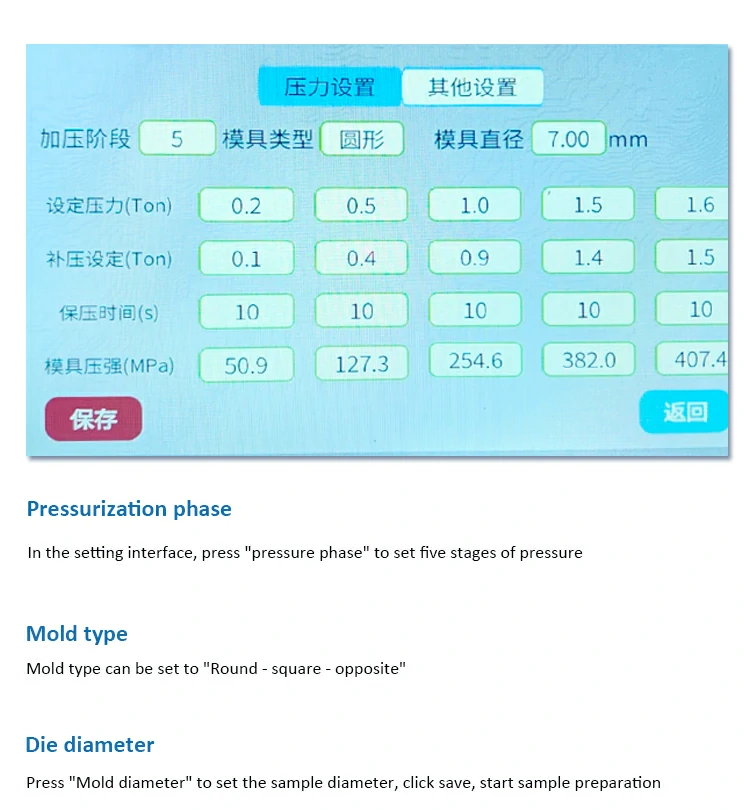

Pressurization Phase

In the setting interface, press Pressure Phase to configure up to five stages of pressure. -

Mold Type

The mold type can be set to Round, Square, or Opposite. -

Die Diameter

Press Mold Diameter to set the sample diameter, then click Save to start sample preparation.

About Hench Technology Co., Ltd.

Hench Technology Co., Ltd. is a leading manufacturer specializing in high-quality laboratory equipment. With a focus on innovation and customer satisfaction, Hench offers a wide array of products, including hydraulic presses and lab supplies, to support scientific research and industrial applications. As trusted hydraulic press suppliers, we are committed to delivering excellence and reliability in every product.

-

-

Electric Lab Tablet Press 0.2-60 Ton

Automatic Hydraulic Press for Laboratory

HDP Series electric laboratory hydraulic press saves time and effort, and is widely used in fields such as new materials, superconductivity, powder ceramics, new-type power supplies, batteries, building materials and metallurgical powders. It can be seamlessly integrated with analytical instruments including calcium-iron analyzers, infrared spectroscopy (IR) and X-ray fluorescence (XRF) spectrometers.

Specifications

Parameter Specification Model HDP-20 / HDP-30 / HDP-40 / HDP-60S Pressure Range 0.2-60T (Optional) Accuracy Range 0.1 T Cylinder Diameter 130 mm Piston Travel 50 mm Pressure Dies Electric PCB program buffer pressure, automatic pressure, manual pressure relief Screen Display 4.5-inch capacitive touch LCD, English interface Pressure Stability ≤ 1 MPa / 10 min Overall Structure Forged, integrated, leak-free design Limit Function Automatic pressure relief above cylinder limit height Safety Protection Plexiglass protective door with snap lock Passive Safety Program pressure mechanical fault reporting, emergency stop, leakage protection Number of Columns 4 Table Diameter Φ148 mm Dwell Time Unlimited (N seconds) Setting Method Touch screen direct modification (fast and convenient) Power Supply 220V (50/60Hz), customizable 110V Power 550 W Effective Space 145 × 145 × 180 mm Size 350 × 390 × 625 mm Weight 111 Kg Special Notes 30T and above models include protective doors; 220V input voltage, touch screen operation, fast boost voltage

Hench Lab Hydraulic Press Key Features

-

Durable and Long-Lasting

Our lab pellet press is built with high-quality materials, ensuring it is durable, not easy to rust, and reliable for long-term laboratory use.

-

User-Friendly Operation

The electric hydraulic press design makes it easy to operate, providing intuitive controls for smooth workflow and fast sample preparation.

-

Precise and Reliable Performance

Equipped with advanced mechanisms, the press delivers precise pressure control, guaranteeing consistent and accurate results every time.

-

Practical and Aesthetic Design

Combines beauty and practicality, with a compact, lab-friendly structure suitable for any laboratory environment.

Product Details

-

Precision Control: Handwheel, High-lead Screw, and Rotary Knob.

-

Structure: Heavy-duty Stand Columns and Stable Working Pressure Table.

-

Interface: Digital Touch Screen Display for real-time monitoring.

-

Safety Features: High-transparency Plexiglass Shielding and Emergency Braking (E-stop).

Operating Procedure

1. Load the sample into the mold and assemble the mold.

2. Place the mold into the hydraulic press and tighten the lead screw.

3. Close the protective door and tighten the side handle.

4. Set the target pressure and refill pressure.

5. Press Start to increase the pressure.

6. Hold the pressure for 30 seconds, then press Stop and loosen the knob to relieve the pressure.

7. Take out the mold, turn it upside down, pull out the base, and insert the release sleeve.

8. Press Start to withdraw the film.

9. When the die releases, press Stop and loosen the knob.

10. Remove the mold and check the sample.

About Hench Technology Co., Ltd.

Hench Technology Co., Ltd. is a leading manufacturer specializing in high-quality laboratory pellet press. With a focus on innovation and customer satisfaction, Hench offers a wide array of products, including hydraulic press machine and lab supplies, to support scientific research and industrial applications. As trusted hydraulic press suppliers, we are committed to delivering excellence and reliability in every product. Contact us for the latest laboratory hydraulic press price!

-

-

15/24/30/40/60-ton Manual Digital Display Protective Laboratory Hydraulic Press YP-FS

Manual Digital Display Protective Laboratory Hydraulic Press

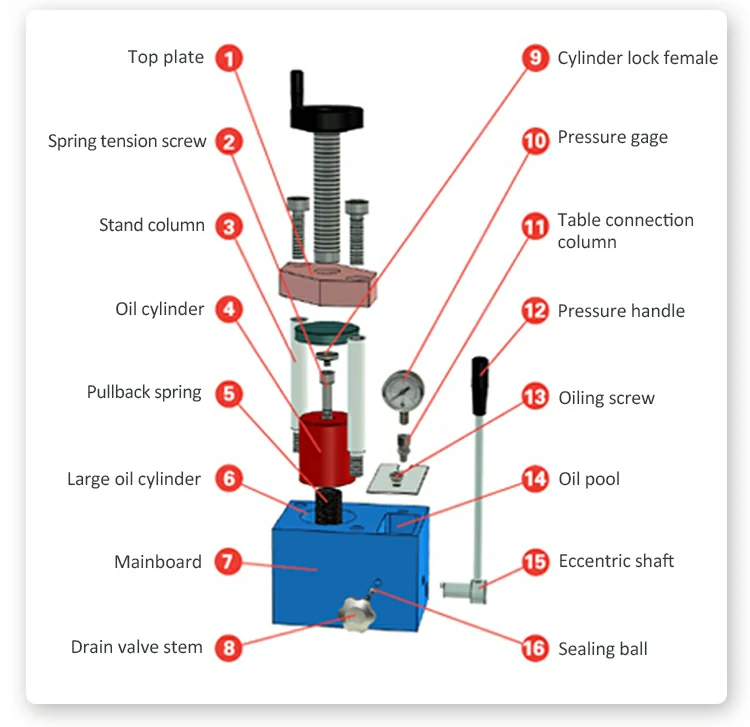

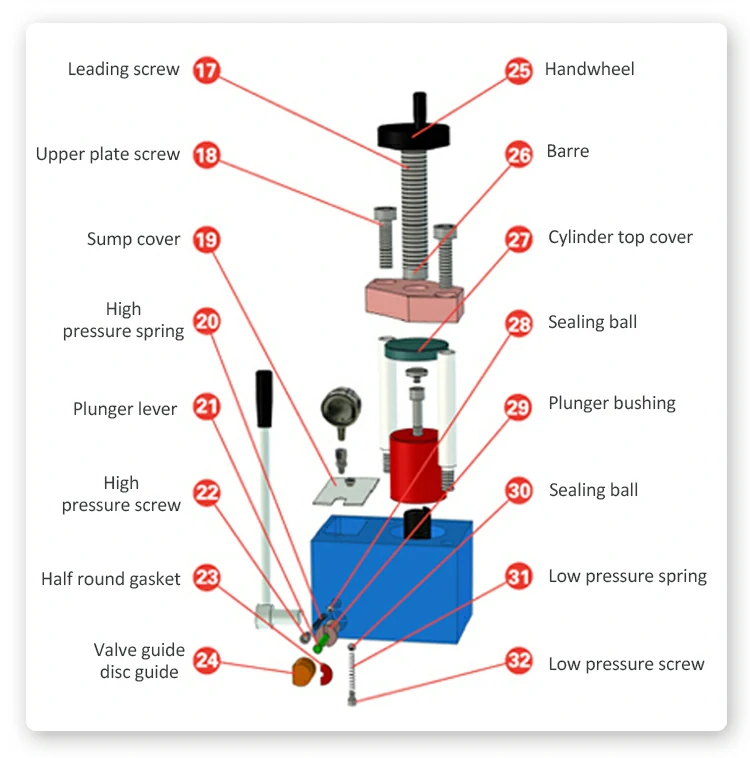

The YP-FS series manual protective hydraulic press features attractive appearance, easy operation, sophisticated craftsmanship, and compact structure. Its integrated structure integrates the cylinder, oil reservoir, mainboard, and piston into a single unit, making the instrument easy to maintain. The imported pressure sensor provides excellent pressure stability and is highly favored by users both domestically and internationally.

Product features

Reliable Hydraulic Press Technology

This press features a robust integrated structure combining the cylinder, piston, and base plate, providing high stability and durability. The high-precision DDNT digital sensor display ensures accurate pressure measurement with a 0.01-ton resolution. For other professional solutions, Hench provides a full range of hydraulic press machines suitable for various laboratory needs.

Designed for Laboratory Applications

Compact and user-friendly, the YP-FS Series enables technicians to operate safely and efficiently. Its protective features, including a plexiglass safety door and emergency stop, ensure safe operation even under high pressure. In addition, Hench offers a comprehensive selection of lab supplies that complement the hydraulic press to optimize laboratory workflows.

Digital Control and Safety

The press includes a digital pressure meter and an optional 4.5-inch LCD interface for precise monitoring. It supports multi-stage pressure adjustment to meet different testing requirements. Hench also provides advanced options such as the digital hydraulic press series for applications requiring higher automation.

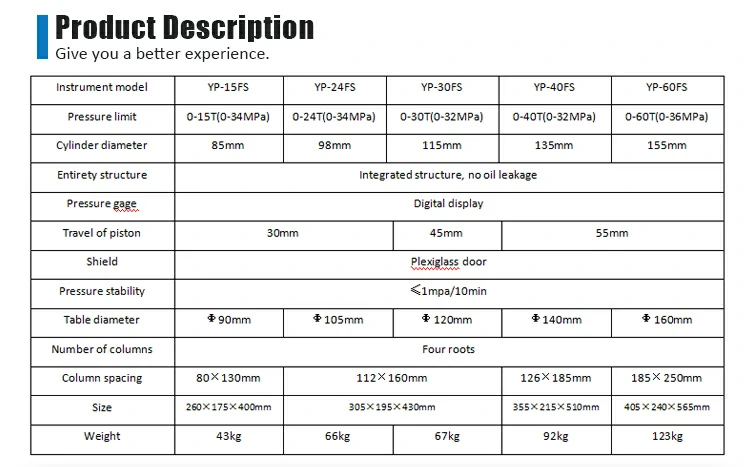

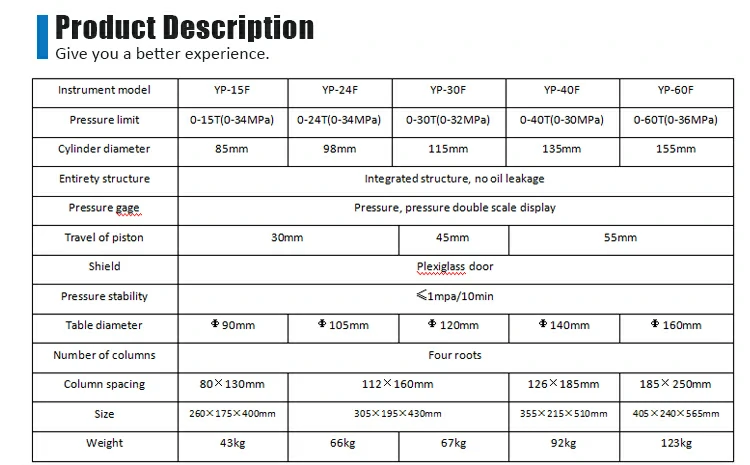

Product Description

Instrument model YP-15FS YP-24FS YP-30FS YP-40FS YP-60FS Pressure limit 0-15T(0-34MPa) 0-24T(0-34MPa) 0-30T(0-32MPa) 0-40T(0-32MPa) 0-60T(0-36MPa) Cylinder diameter 85mm 98mm 115mm 135mm 155mm Entirety structure Integrated structure, no oil leakage Pressure gage Digital display Travel of piston 30mm 45mm 55mm Shield Plexiglass door Pressure stability <1mpa/10min Table diameter Φ 90mm Φ105mm Φ120mm Φ140mm Φ160mm Number of columns Four roots Column spacing 80×130mm 112×160mm 126×185mm 185×250mm Size 260×175×400mm 305×195×430mm 355×215×510mm 405×240×565mm Weight 43kg 66kg 67kg 92kg 123kg Operating Procedure

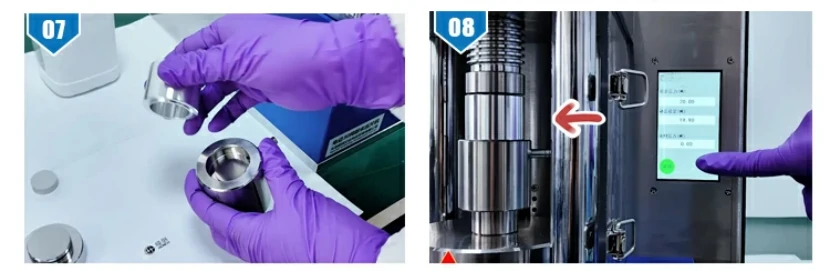

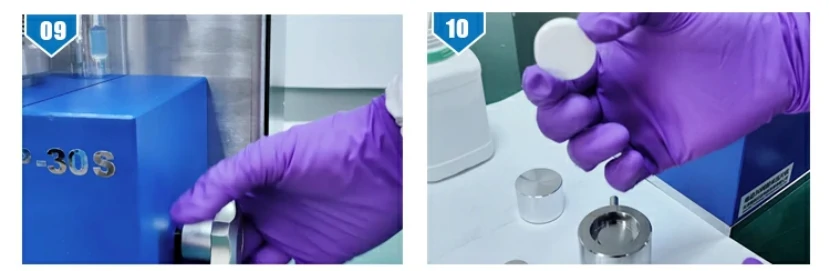

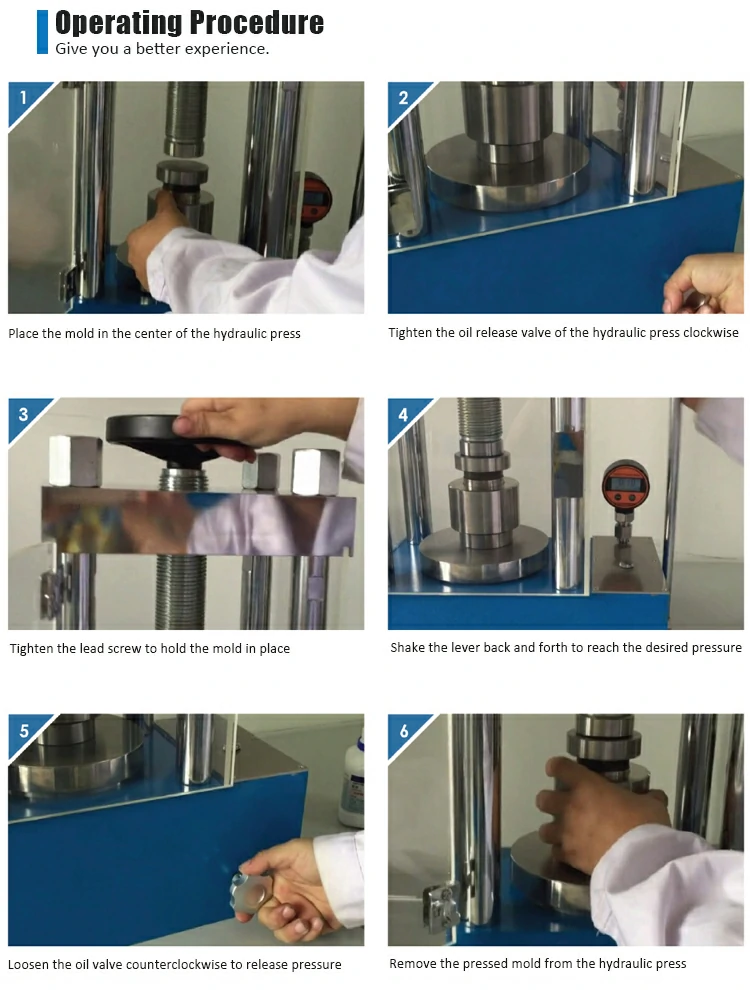

-

Place the mold in the center of the hydraulic press.

-

Tighten the oil release valve of the hydraulic press clockwise.

-

Tighten the lead screw to hold the mold in place.

-

Shake the lever back and forth until the desired pressure is reached.

-

Loosen the oil release valve counterclockwise to release the pressure.

-

Remove the pressed mold from the hydraulic press.

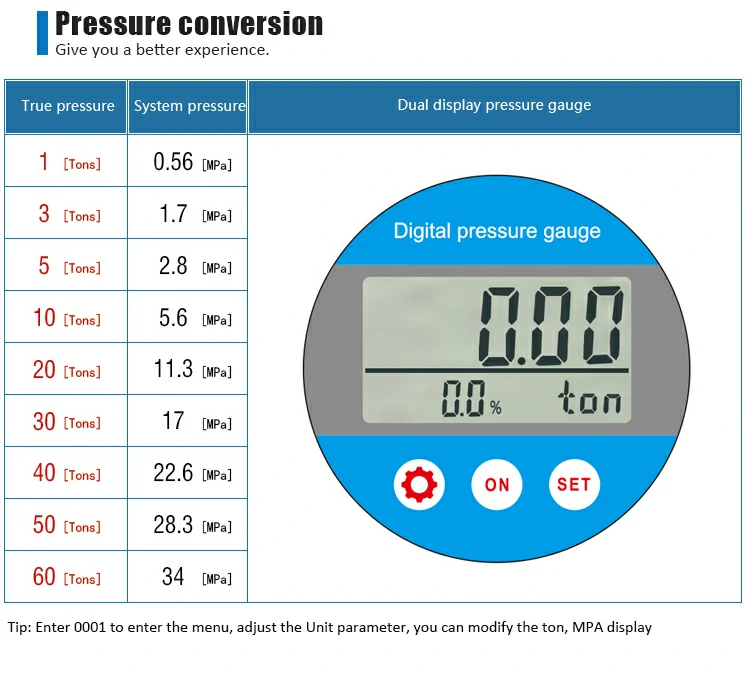

Pressure Conversion

True pressure System pressure 1 Tons 0.56 MPa 3 Tons 1.7 MPa 5 Tons 2.8 MPa 10 Tons 5.6 MPa 20 Tons 11.3 MPa 30 Tons 17 MPa 40 Tons 22.6 MPa 50 Tons 28.3 MPa 60 Tons 34 MPa Tip: Enter 0001 to enter the menu, adjust the Unit parameter, you can modify the ton, MPA display.

About Hench

Hench Technology Co., Ltd. is a leading manufacturer of laboratory equipment with decades of experience. As trusted hydraulic press suppliers, Hench emphasizes precision, safety, and reliability across its product range. Their laboratory presses and other high-quality hydraulic and lab equipment support scientific research and industrial applications worldwide.

-

-

15/24/30/40/60-ton Manual Pointer Protective Lab Powder Pressing Machine YP-F

Manual Pointer Protective Lab Powder Pressing Machine

The YP-F series manual protection hydraulic press adopts a pointer-type pressure gauge with dual scale display of pressure and pressure. There is no conversion noise when applying pressure to avoid overpressure of the mold. It is equipped with an organic plastic protective cover and complies with relevant safety regulations.

Product Features

Robust Hydraulic Press Design

The YP-F Series integrates the cylinder, piston, and base plate into a single, stable structure to ensure reliability and reduce maintenance needs. The high-precision pointer gauge allows accurate pressure readings, meeting rigorous lab testing requirements. Hench offers a complete range of hydraulic press machines to meet diverse laboratory and industrial needs.

Laboratory-Focused Functionality

Designed for efficiency and safety, this lab powder pressing machine features a protective plexiglass door and emergency stop mechanism to prevent accidents. Its compact footprint makes it ideal for crowded lab spaces while maintaining precision under heavy loads. Hench also provides an extensive selection of lab supplies to complement its presses and improve lab workflow.

Enhanced Control and Safety

The YP-F Series supports multi-stage pressure adjustments for various sample types. For labs requiring more advanced monitoring and automation, Hench’s digital hydraulic press series offers precise digital controls and additional safety features.

Product Description

Instrument model YP-15F YP-24F YP-30F YP-40F YP-60F Pressure limit 0-15T(0-34MPa) 0-24T(0-34MPa) 0-30T(0-32MPa) 0-40T(0-30MPa) 0-60T(0-36MPa) Cylinder diameter 85mm 98mm 115mm 135mm 155mm Entirety structure Integrated structure, no oil leakage Pressure gage Pressure, pressure double scale display Travel of piston 30mm 45mm 55mm Shield Plexiglass door Pressure stability <1mpa/10min Table diameter Φ 90mm Φ105mm Φ120mm Φ140mm Φ160mm Number of columns Four roots Column spacing 80×130mm 112×160mm 126×185mm 185×250mm Size 260×175×400mm 305×195×430mm 355×215×530mm 405×240×585mm Weight 43kg 66kg 67kg 92kg 123kg Operating Procedure

-

Place the mold in the center of the hydraulic press.

-

Tighten the oil release valve of the hydraulic press clockwise.

-

Tighten the lead screw to secure the mold.

-

Shake the lever back and forth until the desired pressure is reached.

-

Loosen the oil release valve counterclockwise to release the pressure.

-

Remove the pressed mold from the hydraulic press.

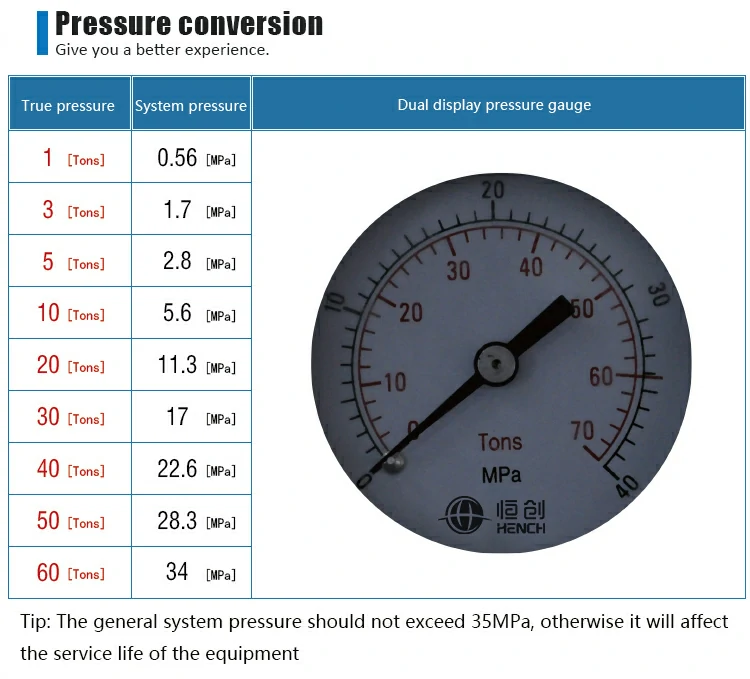

Pressure Conversion

True pressure System pressure 1 Tons 0.56 MPa 3 Tons 1.7 MPa 5 Tons 2.8 MPa 10 Tons 5.6 MPa 20 Tons 11.3 MPa 30 Tons 17 MPa 40 Tons 22.6 MPa 50 Tons 28.3 MPa 60 Tons 34 MPa Tip: The general system pressure should not exceed 35MPa, otherwise, it will affect the service life of the equipment.

About Hench

Hench Technology Co., Ltd. is a trusted manufacturer of high-quality laboratory equipment. As experienced hydraulic press suppliers, Hench focuses on producing reliable and durable equipment that supports scientific research and industrial testing worldwide. Their products, including lab presses and other hydraulic and lab equipment, are recognized for precision, safety, and longevity.

-

-

15/24/30/40-ton Manual Digital Laboratory Press Machine YP-S

Manual Digital Laboratory Press Machine

YP-S series manual digital display hydraulic press adopts digital display pressure gauge with pressure display accuracy of 0.0lMpa, which has higher accuracy and more precise pressure control, and can meet the test requirements of fluorescence preparation spectrometer.

Product features

Compact Integrated Design

The press integrates the oil cylinder, piston, and master plate into a single unit.

This reduces potential leakage points and improves overall durability.Accurate Digital Display

A DDNT digital sensor meter ensures pressure accuracy with a resolution of 0.01 tons.

Stable holding performance (≤1 MPa per 10 min) guarantees consistent test results.Laboratory-Friendly Dimensions

The YP-S offers a compact size of 275 × 210 × 475 mm.

Its effective working space is 92 × 92 × 160 mm, with a Φ120 mm worktable.

A 40 mm piston stroke provides flexibility for various sample types.Safety Features

The machine is equipped with a protective plexiglass cover to safeguard operators.

Overpressure protection and emergency stop functions add extra layers of safety.Broad Laboratory Use

This press is suitable for scientific research, material testing, and educational laboratories.

It combines a small footprint with high performance for routine powder pressing tasks.Additional Equipment Options

For extended needs, Hench provides a complete series of hydraulic press machines.

Researchers can also find a full catalog of lab supplies to support their experiments.

For other models, Hench offers manual tablet press machines designed for diverse applications.Product Description

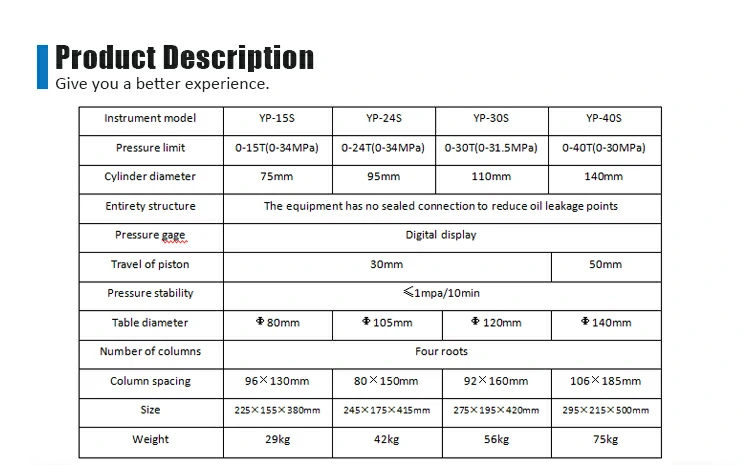

Instrument model YP-15S YP-24S YP-30S YP-40S Pressure limit 0-15T(0-34MPa) 0-24T(0-34MPa) 0-30T(0-31.5MPa) 0-40T(0-30MPa) Cylinder diameter 75mm 95mm 110mm 140mm Entirety structure The equipment has no sealed connection to reduce oil leakage points Pressure gage Digital display Travel of piston 30mm 50mm Pressure stability ≤1mpa/10min Table diameter Φ80mm Φ105mm Φ120mm Φ140mm Number of columns Four roots Column spacing 96×130mm 80×150mm 92×160mm 105×185mm Size 225×155×380mm 245×175×415mm 255×195×420mm 295×215×500mm Weight 29kg 42kg 56kg 75kg Operating Procedure

-

Place the mold in the center of the hydraulic press.

-

Tighten the oil release valve of the tablet press clockwise.

-

Tighten the lead screw to secure the mold.

-

Shake the lever back and forth until the desired pressure is reached.

-

Loosen the oil release valve counterclockwise to release the pressure.

-

Remove the pressed mold from the hydraulic press.

About Hench Technology

As one of the trusted hydraulic press suppliers, Hench Technology Co., Ltd. focuses on innovation, safety, and durability.

With a wide product range, Hench delivers laboratory presses and lab supplies to universities, research centers, and industrial laboratories worldwide.

-

-

2/3/5/12/15-ton Manual Digital Hydraulic Laboratory Press YP-S

Manual Digital Hydraulic Laboratory Press

YP-S series manual digital display hydraulic press 2-15 tons, adopts double column design, suitable for small mold pressing or occasions with small tonnage requirements but strict pressure accuracy requirements.

Key Performance Features

-

Pressure range: 0–15 tons (0–33 MPa).

-

Cylinder diameter: 75 mm; piston travel: 32 mm.

-

Table diameter: Φ80 mm, with an effective workspace of 92 × 130 mm.

-

Pressure stability: ≤ 1 MPa over 10 minutes. Accurate readings through the DDNT digital sensor display, switching between tonnage (T) and MPa, resolution 0.01 T.

-

Compact footprint: 230 × 160 × 385 mm, weight approx 28 kg. Perfect for labs where space is limited.

Related Product Lines & Supplies

-

For other sizes or styles, we offer a broad range of hydraulic press machines that cover more tonnage and automated features.

-

To complete your laboratory workflow, see Hench’s selection of lab supplies including dies, sample prep tools, accessories.

-

For comparable presses with tablet-making functionality or manual/digital display control, our manual tablet press machines are designed for those needs.

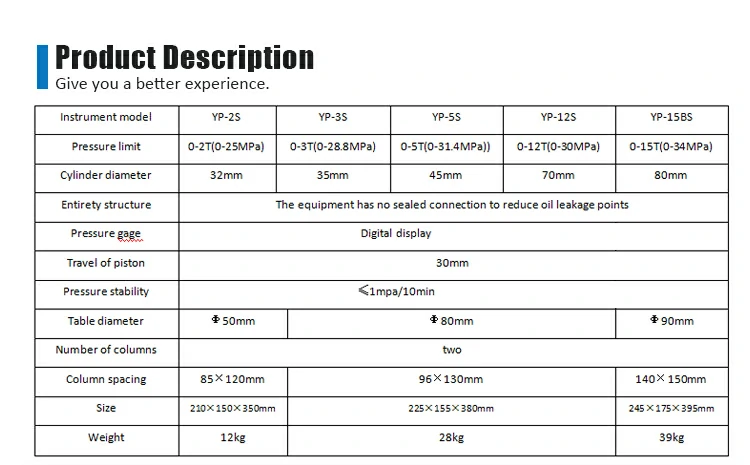

Product Description

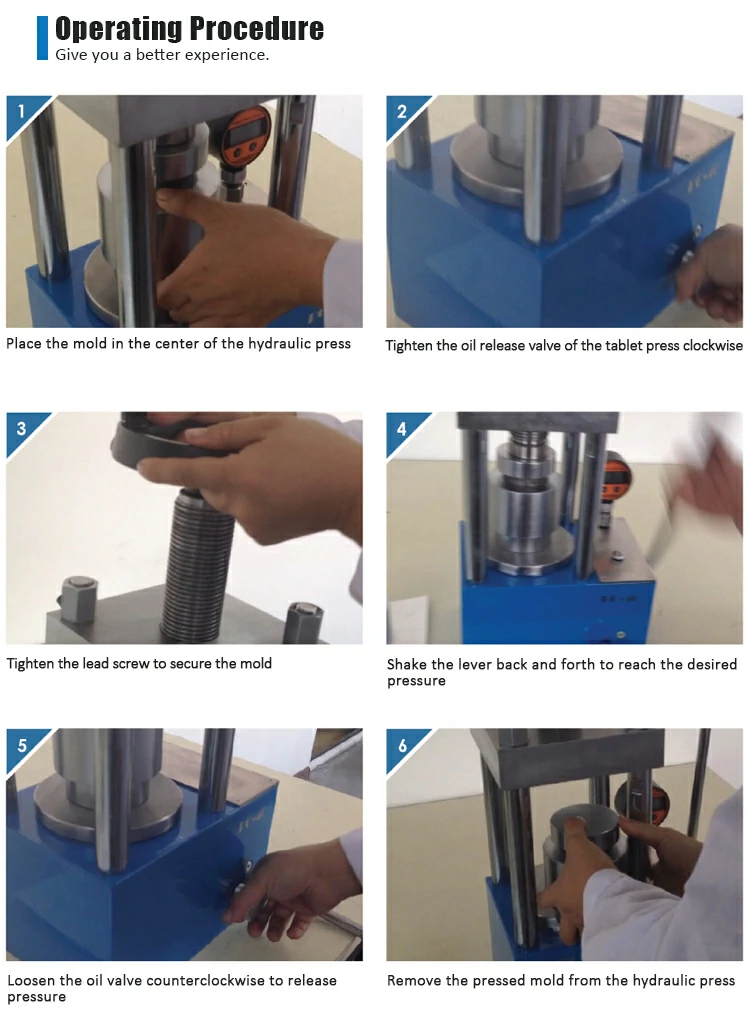

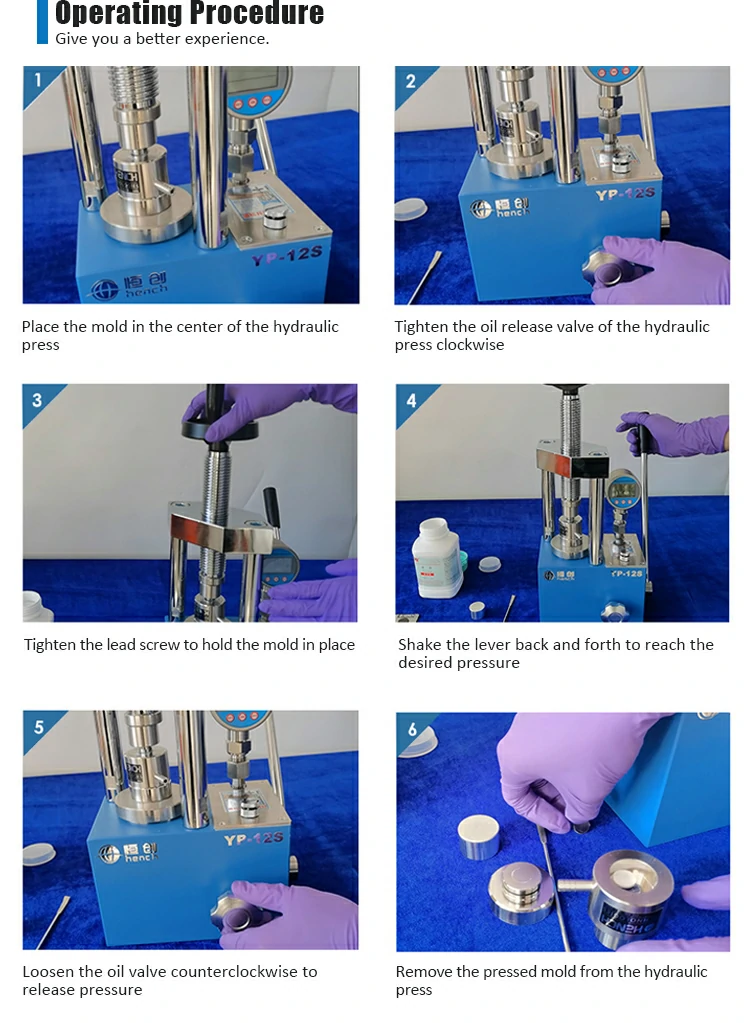

Instrument model YP-2S YP-3S YP-5S YP-12S YP-15BS Pressure limit 0-2T(0-25MPa) 0-3T(0-28.8MPa) 0-5T(0-31.4MPa) 0-12T(0-30MPa) 0-15T(0-34MPa) Cylinder diameter 32mm 35mm 45mm 70mm 80mm Entirety structure The equipment has no sealed connection to reduce oil leakage points Pressure gage Digital display Travel of piston 30mm Pressure stability ≤1mpa/10min Table diameter Φ50mm Φ80mm Φ90mm Number of columns two Column spacing 85×120mm 96×130mm 140×150mm Size 210×150×350mm 225×155×380mm 245×175×395mm Weight 12kg 28kg 39kg Operating Procedure

-

Place the mold in the center of the hydraulic press.

-

Tighten the oil release valve of the hydraulic press clockwise.

-

Tighten the lead screw to hold the mold in place.

-

Shake the lever back and forth until the desired pressure is reached.

-

Loosen the oil release valve counterclockwise to release the pressure.

-

Remove the pressed mold from the hydraulic press.

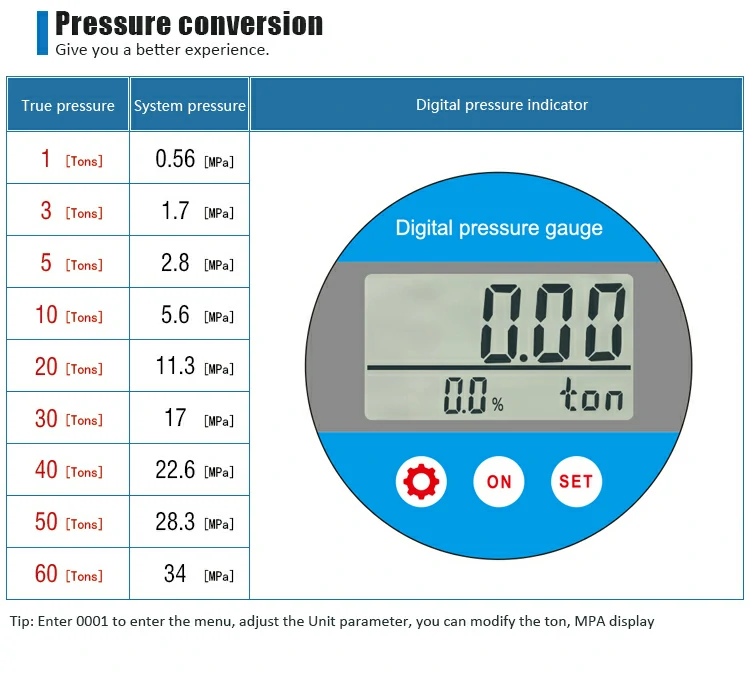

Pressure Conversion

True pressure System pressure 1 Tons 0.56 MPa 3 Tons 1.7 MPa 5 Tons 2.8 MPa 10 Tons 5.6 MPa 20 Tons 11.3 MPa 30 Tons 17 MPa 40 Tons 22.6 MPa 50 Tons 28.3 MPa 60 Tons 34 MPa Tip: Enter 0001 to enter the menu, adjust the Unit parameter, you can modify the ton, MPA display.

About Hench Technology Co., Ltd.

Hench is among the leading hydraulic press suppliers based in Tianjin, China, specializing in precision lab presses and related equipment. Hench combines strong engineering, rigorous quality control, and responsive service. Their equipment supports research labs, industrial testing, and academic institutions, offering both durability and accuracy across product lines.

-

High-Quality Laboratory Presses for Precise Sample Preparation

Hench Technology offers advanced laboratory presses that ensure accurate and reproducible results for a variety of laboratory applications. Designed for efficiency and reliability, these presses are ideal for powders, tablets, and other sample types.

Trusted Lab Equipment Supplier

As a professional lab equipment supplier, Hench Technology provides comprehensive solutions and technical support for laboratory operations. Our commitment to innovation and quality ensures that every laboratory press meets the highest standards.

.png)

.png)