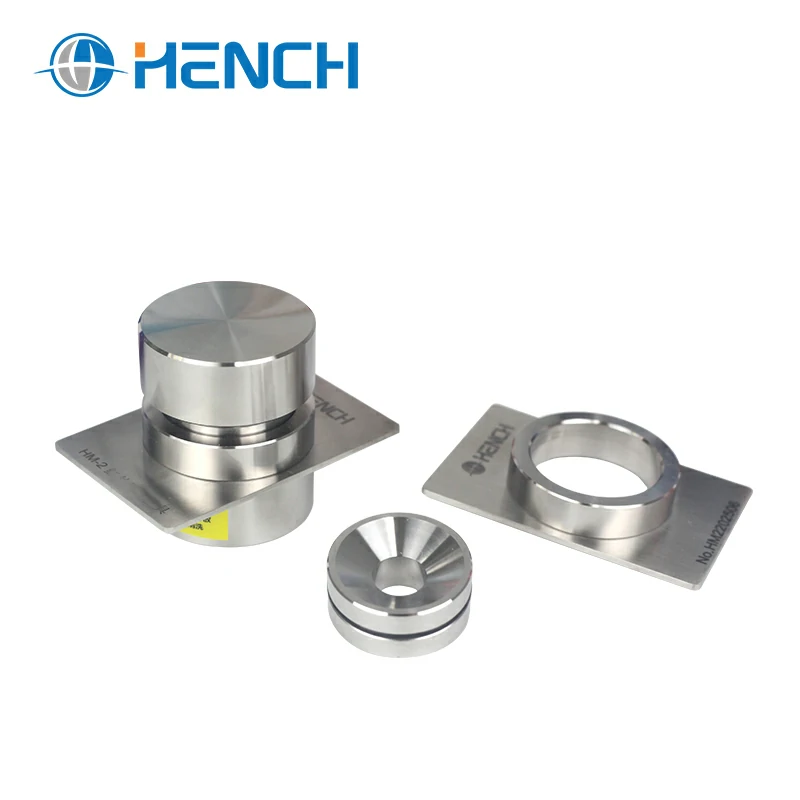

HM-2 13 IR No Demould Dies

IR No Demould Dies Detail

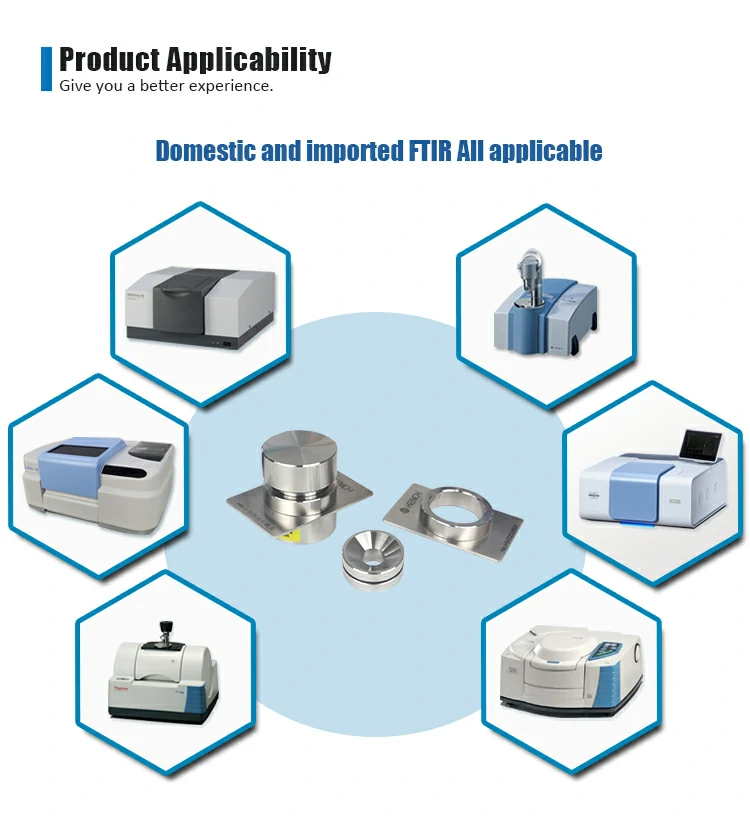

The HM-2 infrared pressing die is a specialized mold for preparing solid powder samples for Fourier transform infrared spectrometers. Made of high-quality alloy tool steel, it features high precision during the pressing process, eliminates the need for demolding, and is easy to operate. This product is compatible with Fourier transform infrared spectrometers from brands such as Beijing Renli, Tianjin Gangdong, Thermo Fisher Scientific, PE, Bruker, and Shimadzu.

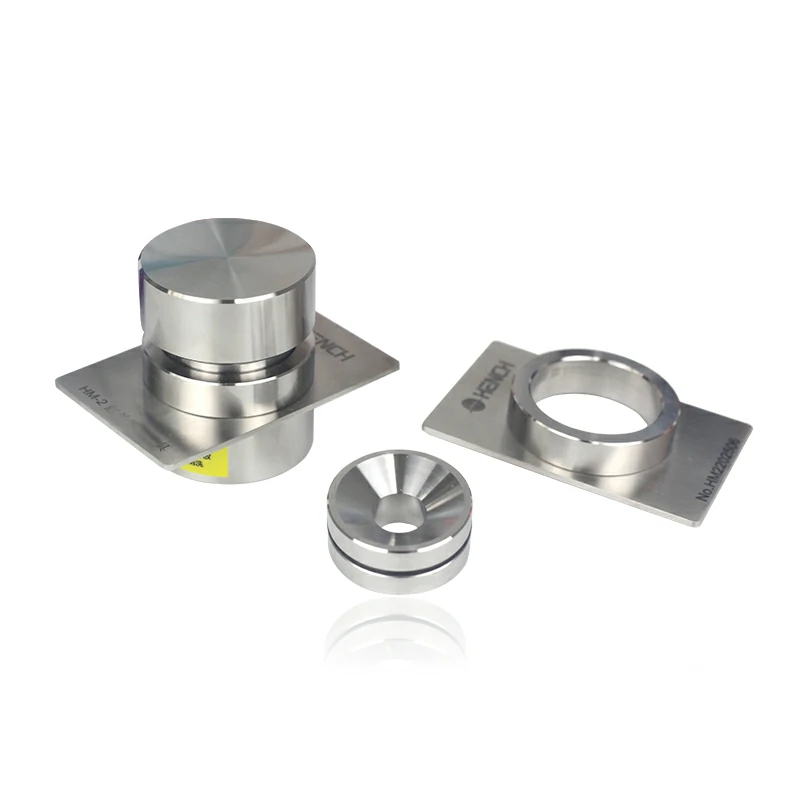

Effortless No-Demould Operation & Universal Compatibility

This die set features a no-demould design—after pressing, you do not need to separately demould the sample. The operation is simple and clean. It works smoothly with all major FTIR spectrometer brands, including Beijing Renli, Tianjin Port East, Thermo (USA), PE (USA), Bruker (Germany), and Shimadzu (Japan). As part of our comprehensive lineup of IR dies, this product delivers efficiency and consistency in labs demanding fast and reliable sample prep.

Ideal Applications & User Benefits

-

Laboratory and R&D environments needing quick sample turnaround without sacrificing quality

-

Solid powder to tablet conversion for infrared spectrometry with high transmittance

-

Users who value minimized handling, greater repeatability, and uniform sample output

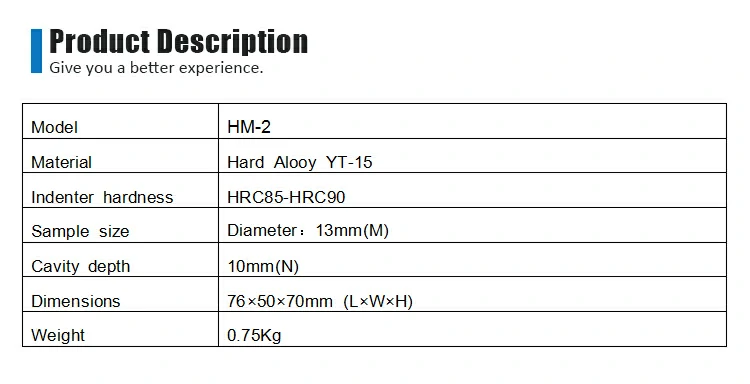

Product Description

| Model | HM-2 |

|---|---|

| Material | Hard Alloy YT-15 |

| Indenter hardness | HRC85-HRC90 |

| Sample size | Diameter: 13mm(M) |

| Cavity depth | 10mm(N) |

| Dimensions | 76×50×70mm (L×W×H) |

| Weight | 0.75Kg |

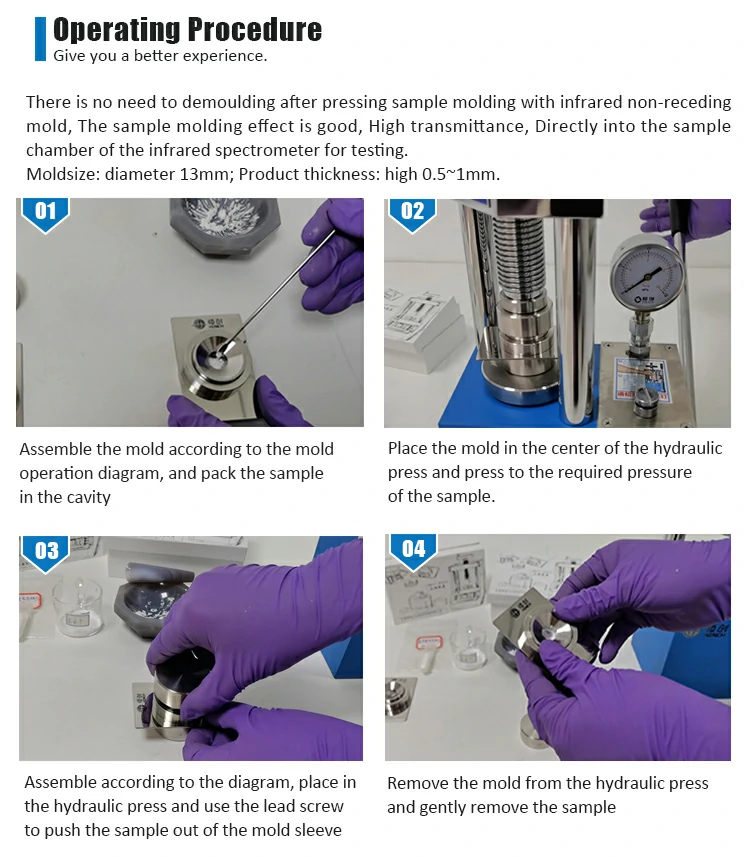

Operating Procedure

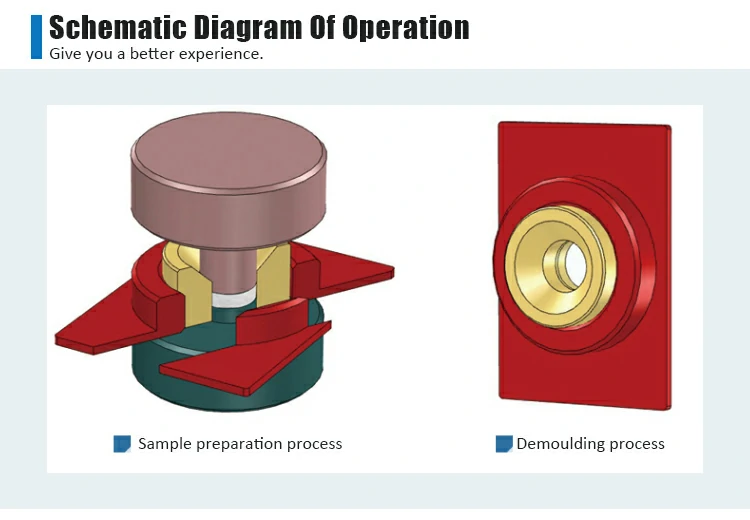

There is no need for demolding after sample molding with the infrared non-receding mold. The sample molding effect is good, with high transmittance, and it can be placed directly into the sample chamber of the infrared spectrometer for testing. Mold size: diameter 13 mm; product thickness: 0.5–1 mm.

-

Assemble the mold according to the operation diagram and pack the sample into the cavity.

-

Place the mold in the center of the hydraulic press and press to the required pressure for the sample.

-

Assemble according to the diagram, place it in the hydraulic press, and use the lead screw to push the sample out of the mold sleeve.

-

Remove the mold from the hydraulic press and gently take out the sample.

About Hench Technology

Hench Technology Co., Ltd., located in Tianjin, China, specializes in designing and manufacturing accessories and equipment for infrared spectroscopy sample preparation. With strong in-house R&D, precision manufacturing, and thorough quality control, Hench produces dies, molds, presses, and full accessory lines. As a respected hydraulic press supplier, we ensure high performance, durability, and reliable customer support.