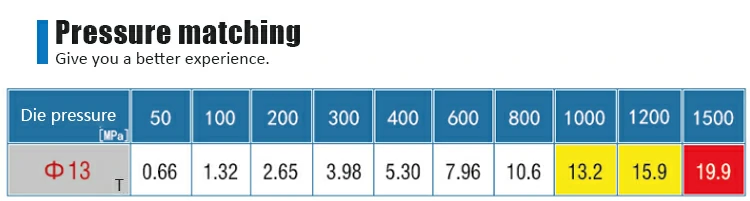

HM-12 13mm IR Tablet Press Dies – Demould

IR Tablet Press Dies Overview

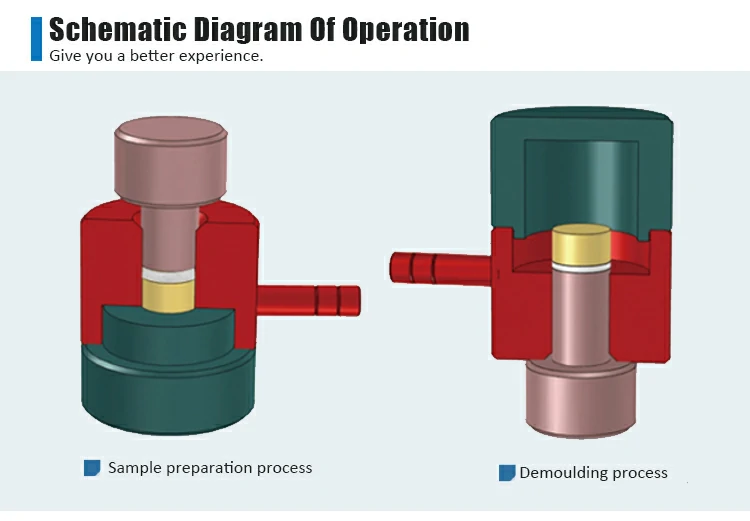

After the infrared non-release mold pressing sample is formed, there is no need for demolding. The sample has a good forming effect and a high transmittance. It can be directly placed in the sample chamber of the infrared spectrometer for testing. Mold size: diameter 13mm; product tablet thickness: height 0.5 - 1mm.

Key Performance & Demould Design Benefits

-

Demould Functionality – After pressing, no demoulding required. The sample formed within the die can be directly placed into the FTIR sample chamber, saving time and reducing handling damage.

-

High Transmittance & Uniformity – With proper pressing pressure adjustments, the tablet exhibits excellent transmittance for infrared spectrometry. The design ensures uniform thickness and minimized scattering.

-

Durable Construction – Mold steel (Chrome 13#) plus high-hardness cemented carbide indenters provide long service life, resistance to wear, and maintain performance over many pressing cycles.

Ideal Applications & Compatibility

This product is perfect for laboratories and research institutions requiring fast, reliable tablet sample preparation. Whether you’re doing routine FTIR analysis, spectral studies, or developing new materials, these dies deliver uniform tablet shape and optical clarity. It belongs to our broader line of IR dies designed for infrared spectroscopy, and is supported by Hench as one of the leading hydraulic press suppliers, ensuring both product quality and supply reliability.

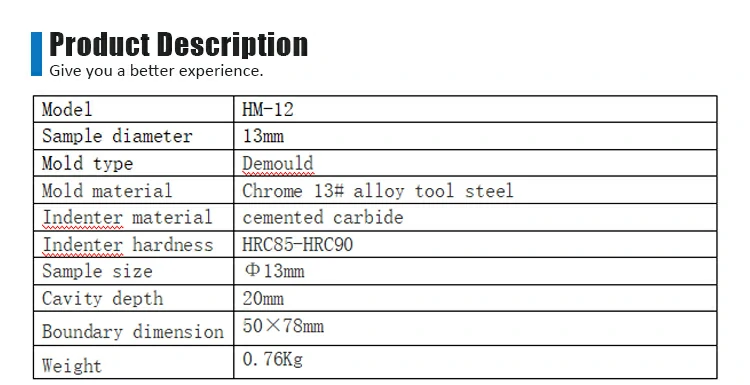

Product Description

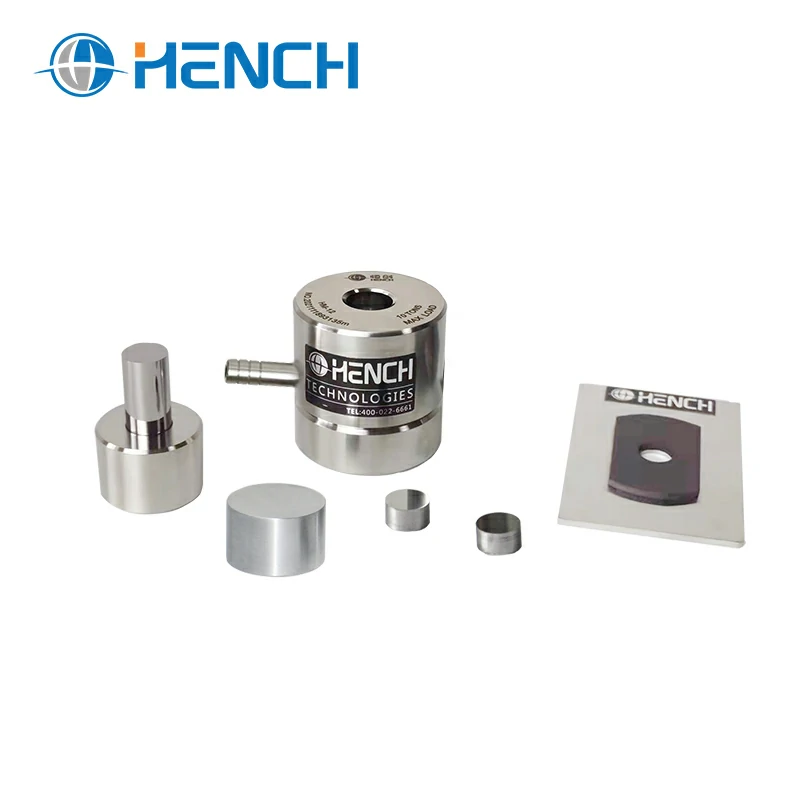

| Model | HM-12 |

|---|---|

| Sample diameter | 13mm |

| Mold type | Demould |

| Mold material | Chrome 13# alloy tool steel |

| Indenter material | cemented carbide |

| Indenter hardness | HRC85-HRC90 |

| Sample size | Φ13mm |

| Cavity depth | 20mm |

| Boundary dimension | 50×78 mm |

| Weight | 0.76kg |

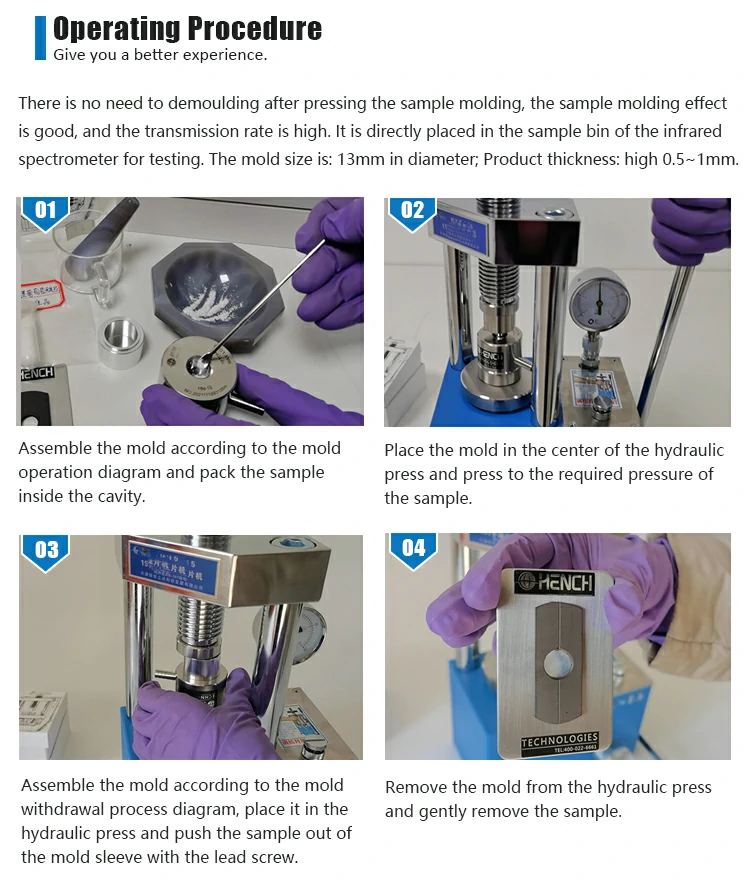

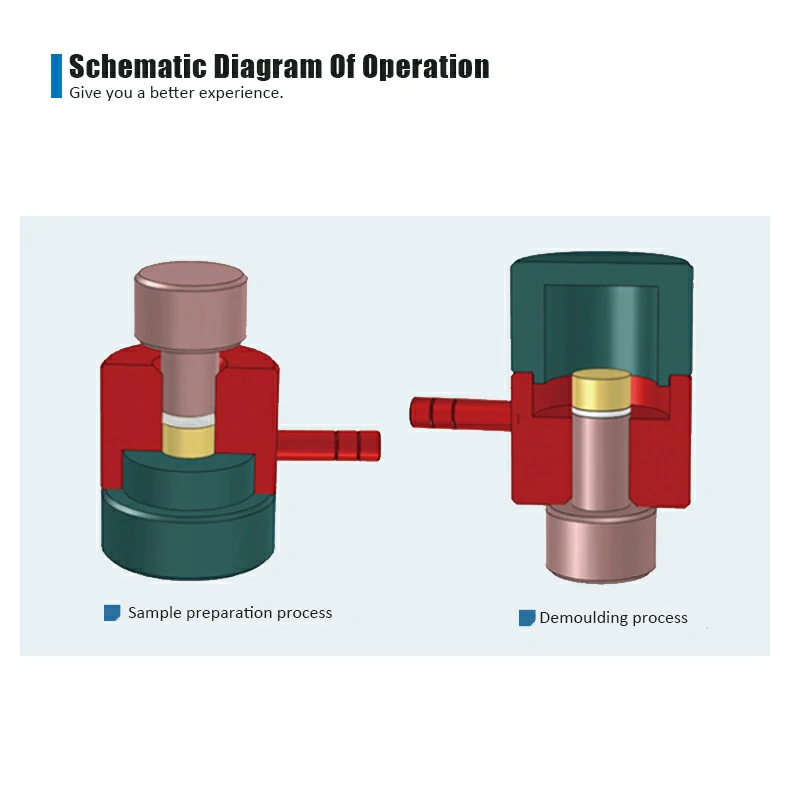

Operating Procedure

There is no need for demolding after pressing the sample. The molding effect is good, and the transmittance is high. The sample can be directly placed in the sample chamber of the infrared spectrometer for testing. The mold size is 13 mm in diameter; product thickness: 0.5–1 mm.

-

Assemble the mold according to the operation diagram and pack the sample inside the cavity.

-

Place the mold in the center of the hydraulic press and press to the required pressure for the sample.

-

Assemble the mold according to the withdrawal process diagram, place it in the hydraulic press, and use the lead screw to push the sample out of the mold sleeve.

-

Remove the mold from the hydraulic press and gently take out the sample.

About Hench Technology

Hench Technology Co., Ltd., headquartered in Tianjin, China, specializes in designing and manufacturing accessories and equipment for infrared spectroscopy sample preparation. With strong R&D capacity and rigorous quality assurance, Hench offers dies, molds, presses, and full solution packages. Our focus is on durability, precision, and enabling efficient workflows for labs worldwide.