Fully Automatic Laboratory Heat Press HZT-800D/DG

Fully Automatic Laboratory Heat Press HZT‑800D/DG

- Temperature control die:5 stages adjustable continuous temperature control - automatic heating - automatic insulation natural cooling

- Control pressure and temperature:0.1T/0.1°C(Customizable accuracy)

- Soaking time:No time limit, reach the set temperature to stop heating

- Display usage:7 inch LCD touch screen/English interface can be switched

- Die pressure conversion:PCB control program automatically converts to display sample pressure (Mpa)

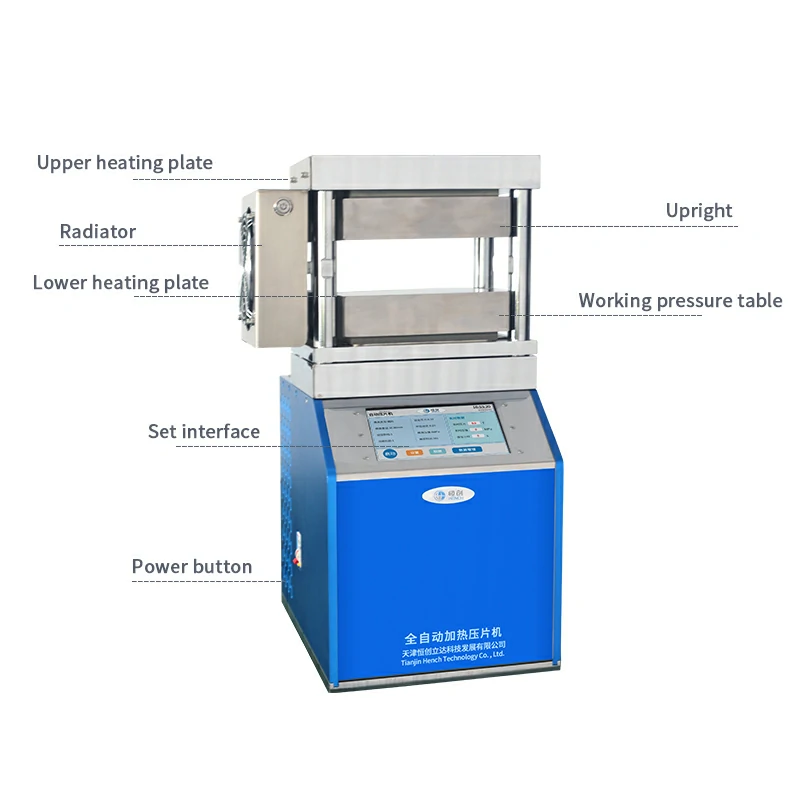

- Heating plate type:Four-column positioning thermal insulation design, upper plate screw suspension designyelectroplated polished panel

- Heating core material:Aluminum heating core/Copper heating core

- Heat insulation method:lmported mica heat insulation board

- Cooling method:Standard wall hanging air cooler

- Passive safety:With leakape protection+emergency stop switch

- Security configuration:Program pressure mechanical failure error emergency stop function, die more than 50'℃, prompt "pay attention to antihot"

- Explain:The control panel size can be customized to increase the width and the column height.

Design & Control Advantages

-

A 7‑inch LCD touch screen allows precise control of both pressure and temperature, delivering repeatable results in research or industrial labs.

-

Safety features include emergency stops, mechanical fault alarms, over-temperature warnings, and an air-cooling system, ensuring reliability during continuous lab operations.

-

Its integrated design and adjustable soaking time make it a preferred choice among advanced hydraulic heat press machines, where controlled heating and pressing are critical.

Applications

Widely used for tablet or pellet preparation, thermo-plastic testing, infrared spectroscopy samples, or any research requiring precise heating under pressure.

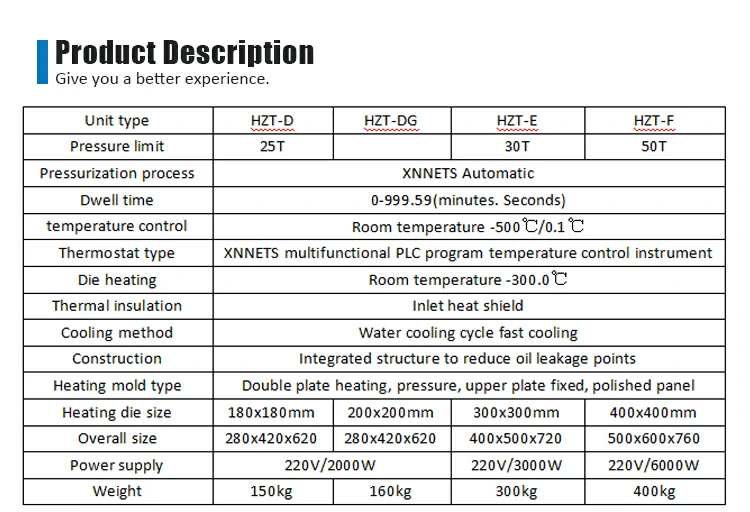

Product Description

| Unit type | HZT-D | HZT-DG | HZT-E | HZT-F |

| Pressure limit | 25T | 30T | 50T | |

| Pressurization process | XNNETS Automatic | |||

| Dwell time | 0-999.59(minutes. Seconds) | |||

| temperature control | Room temperature -500℃/0.1℃ | |||

| Thermostat type | XNNETS multifunctional PLC program temperature control instrument | |||

| Die heating | Room temperature -300.0℃ | |||

| Thermal insulation | Inlet heat shield | |||

| Cooling method | Water cooling cycle fast cooling | |||

| Construction | Integrated structure to reduce oil leakage points | |||

| Heating mold type | Double plate heating, pressure, upper plate fixed, polished panel | |||

| Heating die size | 180x180mm | 200x200mm | 300x300mm | 400x400mm |

| Overall size | 280x420x620 | 280x420x620 | 400x500x720 | 500x600x760 |

| Power supply | 220V/2000W | 220V/3000W | 220V/6000W | |

| Weight | 150kg | 160kg | 300kg | 400kg |

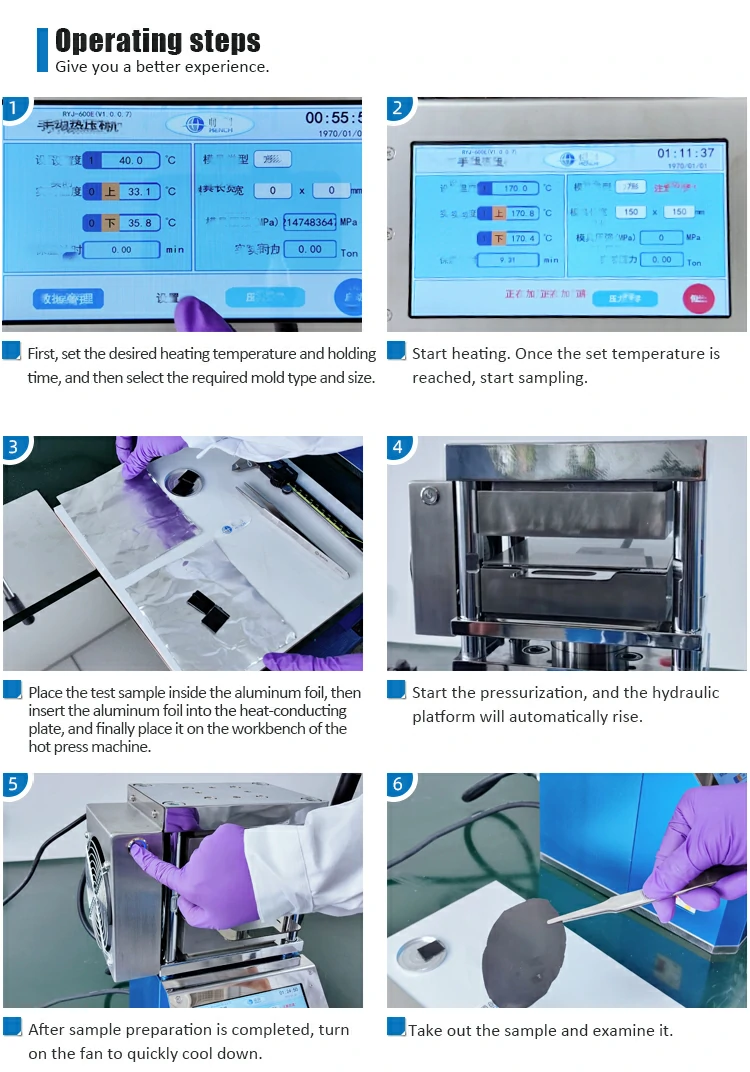

Operating Procedure

-

First, set the desired heating temperature and holding time, and then select the required die type and size.

-

Start heating. Once the set temperature is reached, begin sampling.

-

Place the test sample inside the aluminum foil, then insert the aluminum foil into the heat-conducting plate, and finally place it on the workbench of the hot press machine.

-

Start pressurization, and the hydraulic platform will automatically rise.

-

After sample preparation is completed, turn on the fan to cool down quickly.

-

Take out the sample for examination.

Why Choose Hench?

Hench based in Tianjin, China, is a leading hydraulic press manufacturer specializing in laboratory hot presses, hydraulic heating systems, and precision sample preparation equipment. Hench designs reliable lab supplies that balance performance, safety, and ease of use. Their solutions are trusted worldwide in research institutes, universities, and industrial laboratories.