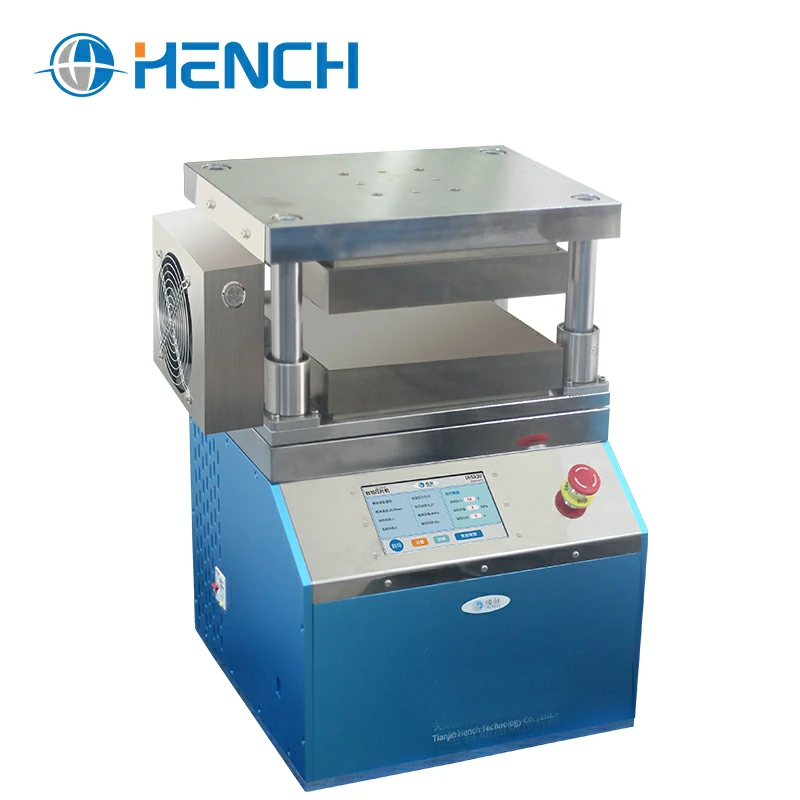

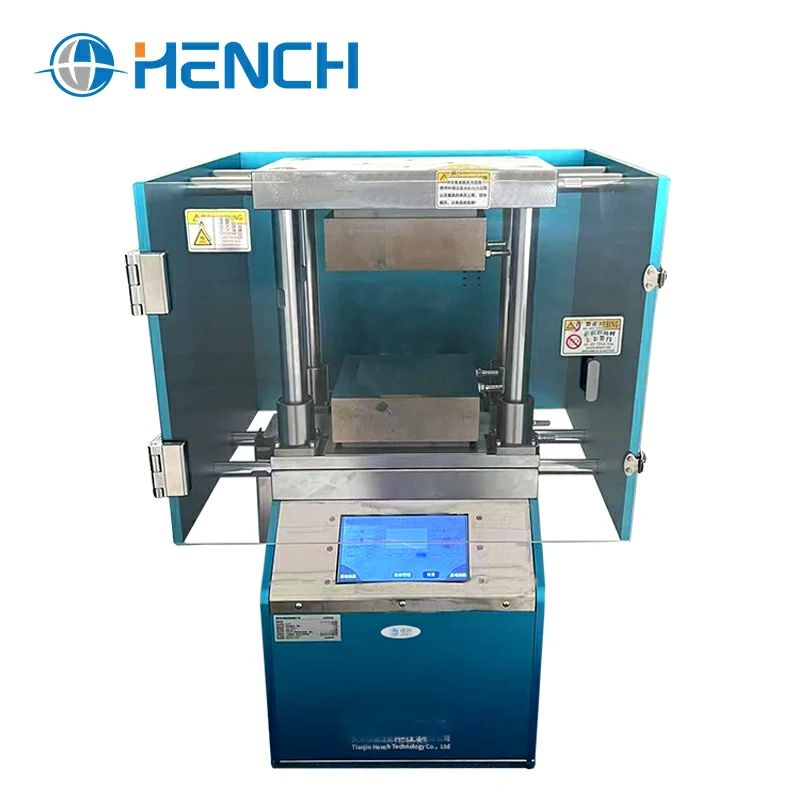

Fully Automatic Heating Laboratory Tablet Press HZT-800E/F/G

Fully Automatic Heating Laboratory Tablet Press Features

ZHT series hot press adopts integrated structure,from dynamic hydraulic drive, four-column positioning heat insulation Settings, lead screw suspension the hot plate is hoisted, with fast pressure,easy to operate ad vantages such as maintenance. Multi-stage temperature control can meet a variety of powder, plastic thin mem brane, rubber material and its solid material for high temperature high repressed-like user use.

Key Features

-

Models & Pressure: Available in 0-30T / 0-40T variants.

-

Piston Diameter & Stroke: Options with 110mm / 130mm pistons, stroke ≈ 55 mm.

-

Temperature & Heating Range: Room temperature up to 600 °C; heating range options up to 300 °C or 500 °C depending on configuration.

-

Die Size & Effective Space: Die plate dimensions of 300×300 mm, 400×400 mm, or 600×600 mm; effective working height around 65 mm.

-

Power, Size & Weight: Models use from 3 kW up to 12.5 kW power; machine dimensions scale (e.g. 400×500×750 mm up to 700×800×1110 mm); weights between ~350 kg to ~450 kg depending on size.

Product Advantages

-

Fully automatic press with integrated structure, four-column positioning and heat insulation. Hot plate is suspended by lead screws, enabling smooth lifting, fast pressure application, and easier maintenance.

-

Multi-stage temperature control accommodates a variety of materials: powders, plastics, thin membranes, rubbers, or other solid samples that require high temperature and consistent pressure.

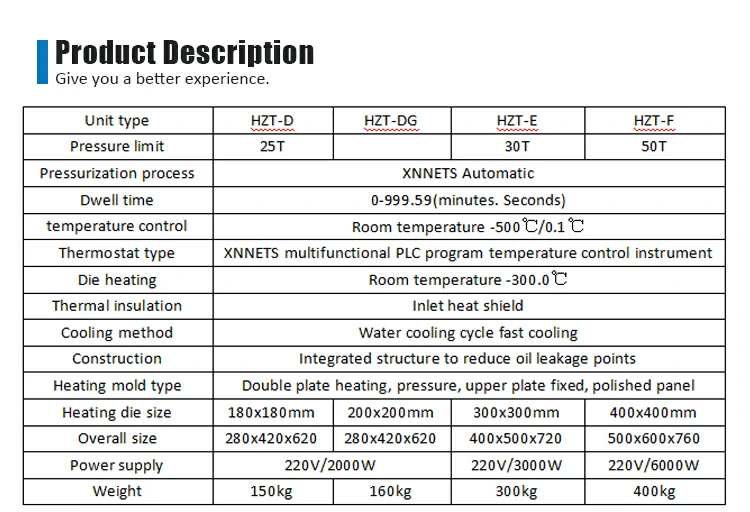

Product Description

| Unit type | HZT-D | HZT-DG | HZT-E | HZT-F |

| Pressure limit | 25T | 30T | 50T | |

| Pressurization process | XNNETS Automatic | |||

| Dwell time | 0-999.59 (minutes. Seconds) | |||

| Temperature control | Room temperature - 500℃ / 0.1℃ | |||

| Thermostat type | XNNETS multifunctional PLC program temperature control instrument | |||

| Die heating | Room temperature - 300.0℃ | |||

| Thermal insulation | Inlet heat shield | |||

| Cooling method | Water cooling cycle fast cooling | |||

| Construction | Integrated structure to reduce oil leakage points | |||

| Heating mold type | Double plate heating, pressure, upper plate fixed, polished panel | |||

| Heating die size | 180×180mm | 200×200mm | 300×300mm | 400×400mm |

| Overall size | 280×420×620 | 280×420×620 | 400×500×720 | 500×600×760 |

| Power supply | 220V / 2000W | 220V / 3000W | 220V / 6000W | |

| Weight | 150kg | 160kg | 300kg | 400kg |

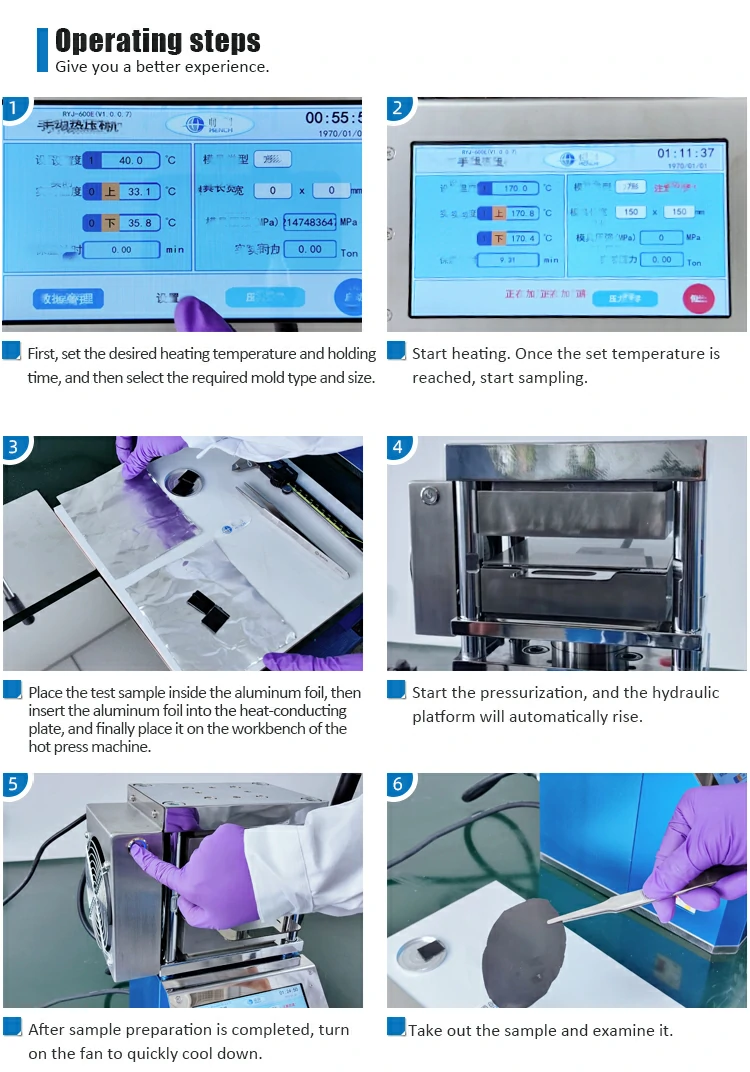

Operating Steps

-

First, set the desired heating temperature and holding time, and then select the required mold type and size.

-

Start heating. Once the set temperature is reached, begin sampling.

-

Place the test sample in the aluminum foil, then insert the foil into the heat-conducting plate, and finally place it on the workbench of the hot press machine.

-

Start pressurization, and the hydraulic platform will automatically rise.

-

After sample preparation is complete, turn on the fan to cool it down quickly.

-

Take out the sample and examine it.

Why Choose Hench?

Hench Technology Co., Ltd., based in Tianjin, China, specializes in manufacturing high-precision lab equipment including heating tablet presses, infrared sample preparation systems, and full ranges of hydraulic press solutions. They are recognized among leading hydraulic press suppliers for combining robust engineering with tailored customer support.

Hench’s product offerings include state-of-the-art hydraulic press machine models as well as specialized hydraulic heat press machine lines. Their machines are designed with safety, repeatability, and ease of operation in mind—making them a strong partner for both academic and industrial users.