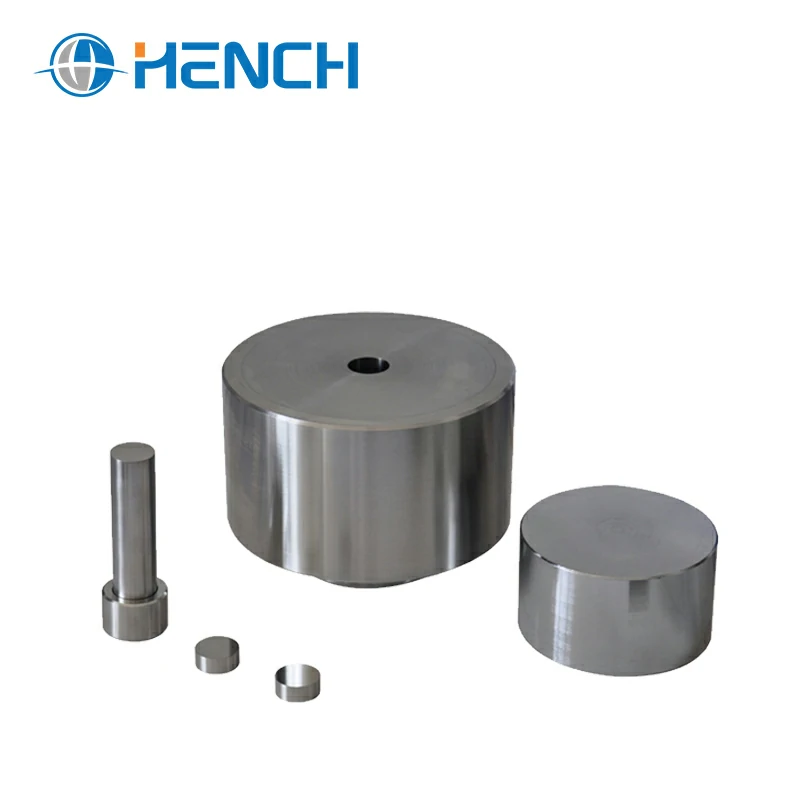

Anti-cracking die 3-20mm HML

The anti-cracking mold is made of imported high-speed tool steel, with a high surface smoothness and strong hardness. It is suitable for material science research.

Catalytic experiments, ceramic sintering experiments, cement building materials, drug research and sample preparation industries. Can be customized according to customer requirements

Manufacture molds of different sizes for making pills.

Product Description

| Model | HML |

| Mold material | Alloy tool steel: Cr12MoV |

| Indenter hardness | HRC60-HRC62 |

| Sample size | 3-20mm |

| Cavity depth | 40mm |

| Boundary dimension | 98×120mm |

| Die weight | 5Kg |

Operating Procedure

Anti-cracking mold is mainly used for ultra-high pressure or cavities with excessive depth, where the mold is easy to crack when pressing.

Pressing size: 3–20mm; Product thickness: 10–40mm; Bulk powder height: 80mm.

Special mold sizes can be customized according to customer requirements.

-

The mold adopts a double-layer structure to prevent cracking and to avoid injury.

-

Assemble the mold according to the drawing.

-

Place the sample in the mold cavity.

-

Insert the press rod, then place the mold into the hydraulic press and apply pressure to the sample.