Square-shaped Split Die 3-100mm HMK-F

Square-shaped Split Die features

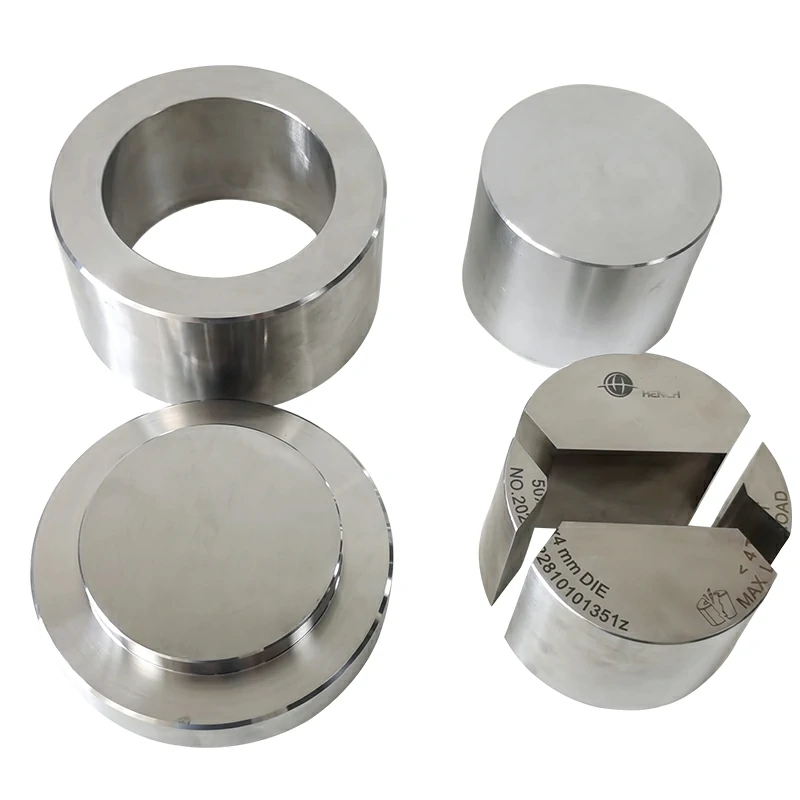

The Square-shaped Split Die is a versatile tool designed for precise powder sample molding in laboratories. Key features include:

-

High-quality material: The main body is made of 440C die steel (quenched to 90°C), and the indenter has a hardness of HRC68–HRC70, ensuring long-lasting durability.

-

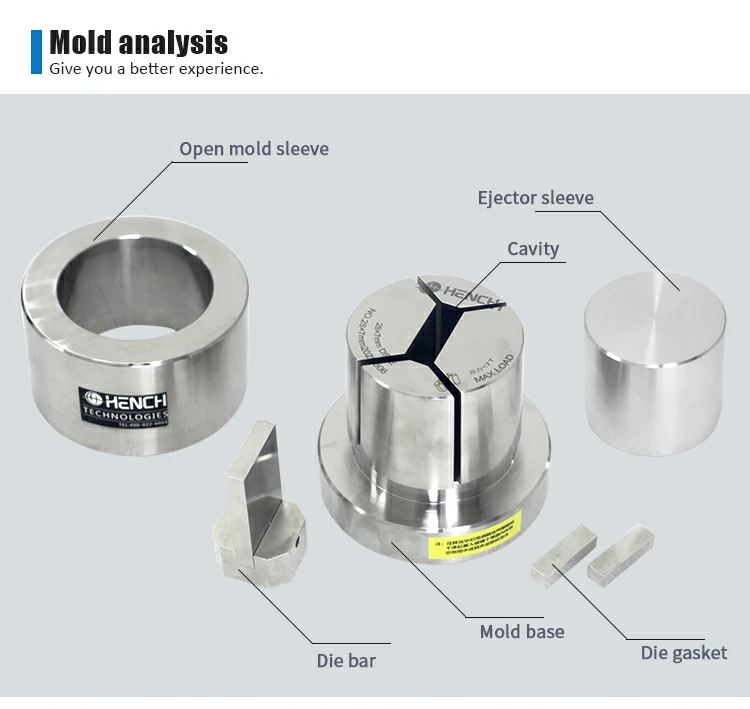

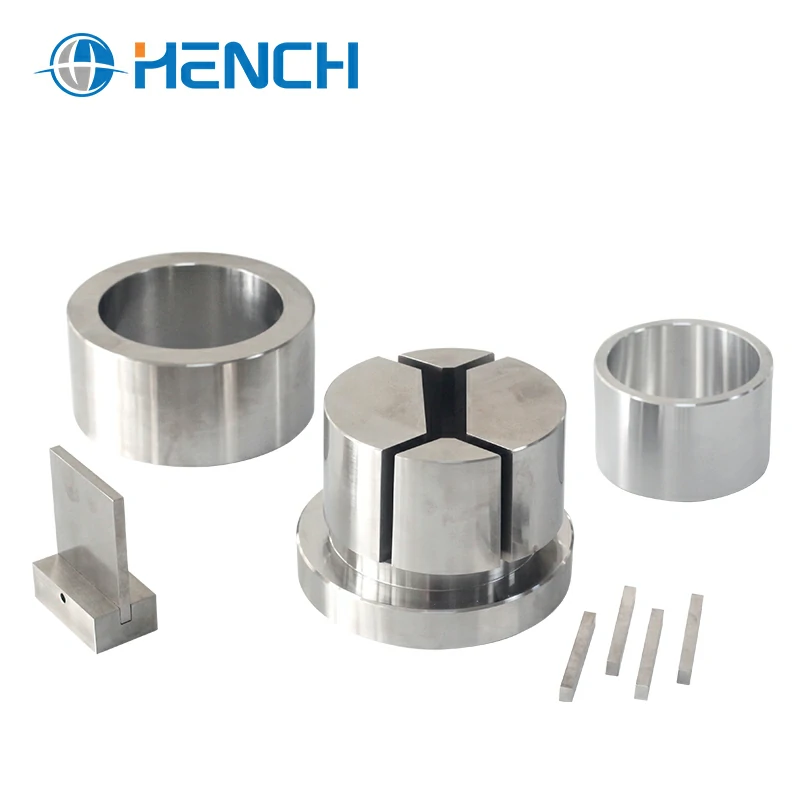

Composite design: Also known as a split die, it generally consists of 3–4 inner cores forming the die cavity, allowing complex shapes to be molded accurately.

-

Versatile applications: Rectangular open dies are suitable for slender strips, while circular open dies handle cylindrical or difficult-to-form samples.

-

Ease of operation: The die is simple to operate and offers fast film retreat speed.

-

Customizable specifications: Users can choose different die sizes and shapes according to specific laboratory requirements.

-

Suitable thickness: Designed for powder samples thicker than 6 mm, providing consistent compaction and uniform sample density.

This reliable pellet die is widely used in material research, pharmaceuticals, and scientific testing. For additional geometries and shapes, the Circular blown dies series offers a variety of options for diverse laboratory applications.

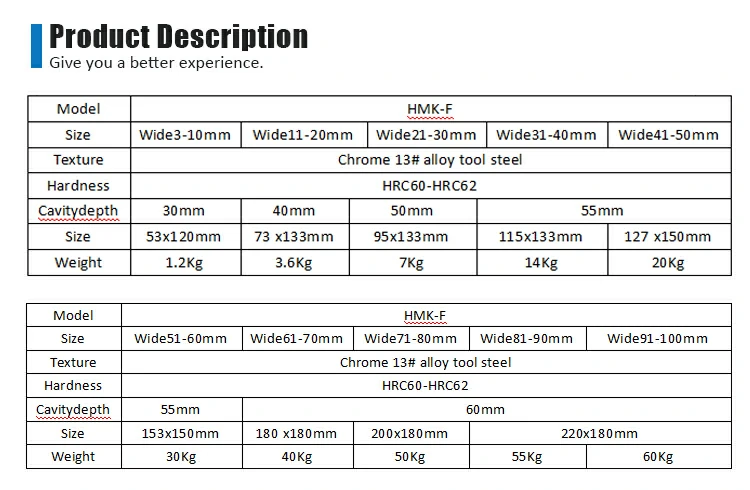

Product Description

| Model | HMK-F | ||||

| Size | Wide3-10mm | Wide11-20mm | Wide21-30mm | Wide31-40mm | Wide41-50mm |

| Texture | Chrome 13# alloy tool steel | ||||

| Hardness | HRC60-HRC62 | ||||

| Cavity depth | 30mm | 40mm | 50mm | 55mm | |

| Dimension | 53x120mm | 73x133mm | 95x133mm | 115x133mm | 127x150mm |

| Weight | 1.2Kg | 3.6Kg | 7Kg | 14Kg | 20Kg |

| Model | HMK-F | ||||

| Size | Wide51-60mm | Wide61-70mm | Wide71-80mm | Wide81-90mm | Wide91-100mm |

| Texture | Chrome 13# alloy tool steel | ||||

| Hardness | HRC60-HRC62 | ||||

| Cavity depth | 55mm | 60mm | |||

| Dimension | 153x150mm | 180x180mm | 200x180mm | 220x180mm | |

| Weight | 30Kg | 40Kg | 50Kg | 55Kg | 60Kg |

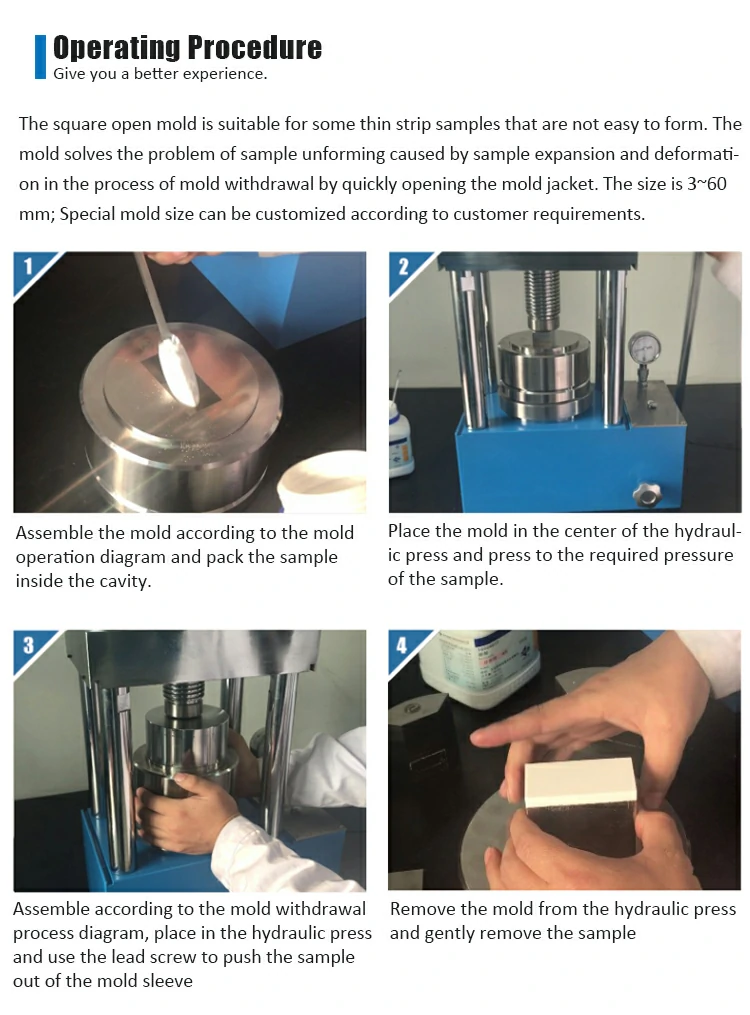

Operating Procedure

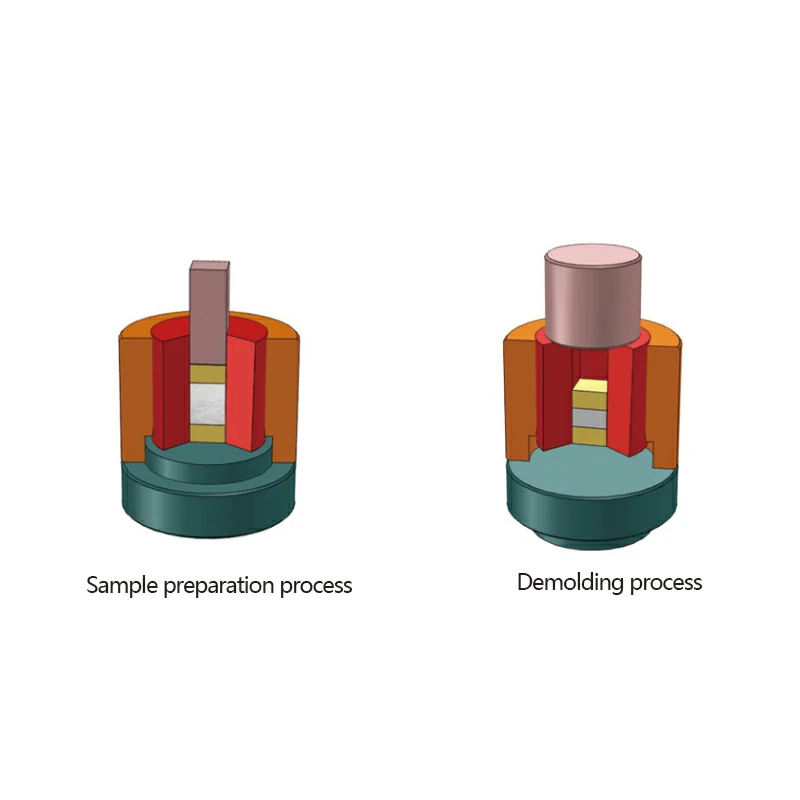

The square open mold is suitable for thin strip samples that are difficult to form.

It solves the problem of incomplete molding caused by sample expansion and deformation during demolding, by quickly opening the mold jacket.

Mold size: 3–60mm. Special mold sizes can be customized according to customer requirements.

-

Assemble the mold according to the mold operation diagram and pack the sample inside the cavity.

-

Place the mold in the center of the hydraulic press and press to the required pressure.

-

Disassemble the mold according to the mold withdrawal process diagram, place it in the hydraulic press, and use the lead screw to push the sample out of the mold sleeve.

-

Remove the mold from the hydraulic press and gently take out the sample.

About Hench

Hench is a professional Laboratory Equipment Supplier providing high-precision dies and laboratory instruments. With a strong focus on accuracy, durability, and innovation, Hench offers square-shaped split dies, pellet dies, and circular blown dies tailored to meet the needs of scientific research, material testing, and pharmaceutical R&D.