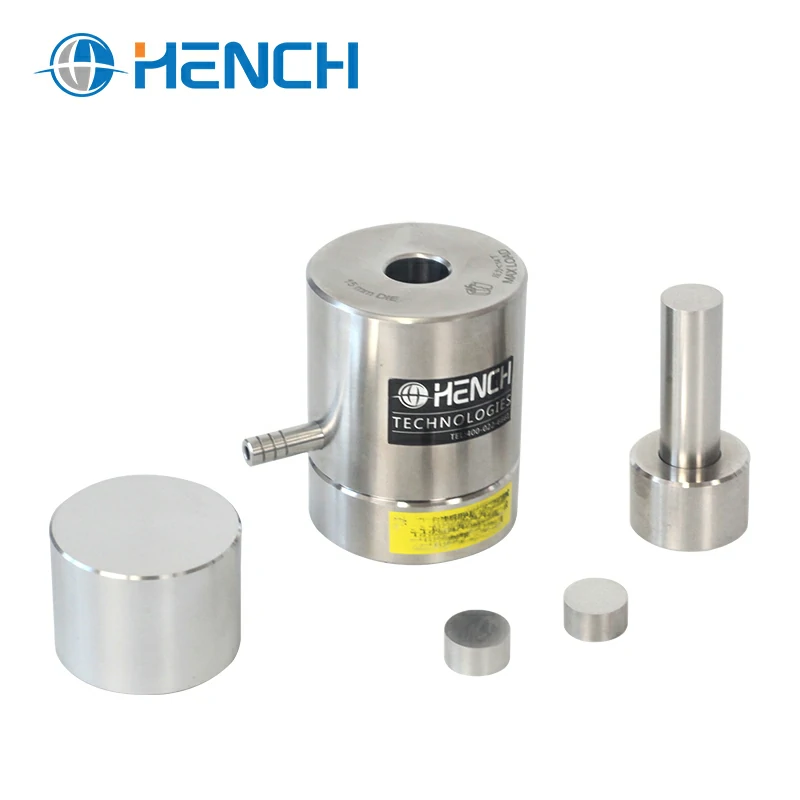

Circular Tablet Press Die 2.0-40.9mm HMY

Product Features

HiMY series circular tableting dies are the most commonly used dies for forming powder samples in laboratories. Used in conjunction with hydraulic presses, they are made of imported high-speed die steel, resulting in a smooth surface and high hardness. They are suitable for materials science research, catalysis experiments, ceramic sintering experiments, cement and building materials, pharmaceutical R&D, and sample preparation. Different sizes can be customized according to customer needs.

Product Description

| Model | HMY | |||

| Sample size | HMY (Φ2.0-6.0mm) | HMY (Φ6.1-14.9mm) | HMY (Φ15.0-25.9mm) | HMY (Φ26.0-40.9mm) |

| Dies material | Chromium 13# alloy tool steel | |||

| Indentation hardness | HRC58 | |||

| Cavity depth | 20mm | 30mm | 40mm | 45mm |

| Size | 43×78mm | 43×93mm | 53×120mm | 73×133mm |

| Weight | 0.55Kg | 0.67Kg | 1.34Kg | 2.9Kg |

Operating Procedure

The cylindrical mold can be used for most sample forming and testing. The size of the sheet: 15~25mm; Product thickness: 1~25mm; Bulk powder height: up to 40mm; Special mold sizes can be customized according to customer requirements.

-

Assemble the mold according to the mold operation diagram and place the sample inside the cavity.

-

Place the mold in the center of the hydraulic press and press it to the pressure required by the sample.

-

Assemble the mold according to the mold withdrawal process diagram, place it in the hydraulic press, and push the sample out of the mold sleeve with the lead screw.

-

Remove the mold from the hydraulic press and gently take out the sample.

| Pressure Diameter | 50 MPa | 100 MPa | 200 MPa | 300 MPa | 400 MPa | 600 MPa | 800 MPa | 1000 MPa | 1200 MPa | 1500 MPa |

| Φ22mm | 1.90 T | 3.80 T | 7.60 T | 11.4 T | 15.2 T | 22.8 T | 30.4 T | 38.0 T | 45.6 T | 57.0 T |

| Φ25mm | 2.45 T | 4.90 T | 9.81 T | 14.7 T | 19.6 T | 29.4 T | 39.2 T | 49.0 T | 58.9 T | 73.6 T |

| Φ28mm | 3.07 T | 6.15 T | 12.3 T | 18.4 T | 24.6 T | 36.9 T | 49.2 T | 61.5 T | 73.8 T | 92.3 T |

| Φ30mm | 3.54 T | 7.06 T | 14.1 T | 21.2 T | 28.2 T | 42.4 T | 56.5 T | 70.6 T | 84.8 T | 106 T |

| Φ32mm | 4.02 T | 8.04 T | 16.0 T | 24.1 T | 32.1 T | 48.2 T | 64.3 T | 80.4 T | 96.5 T | 120 T |

| Φ35mm | 4.81 T | 9.62 T | 19.2 T | 28.8 T | 38.4 T | 57.7 T | 76.9 T | 96.2 T | 115 T | 144 T |

| Φ40mm | 6.28 T | 12.5 T | 25.1 T | 37.6 T | 50.2 T | 75.3 T | 100 T | 125 T | 150 T | 188 T |

| Φ45mm | 7.59 T | 15.9 T | 31.8 T | 47.7 T | 63.6 T | 95.4 T | 127 T | 159 T | 190 T | 238 T |

| Φ50mm | 9.81 T | 19.6 T | 39.2 T | 58.9 T | 78.5 T | 117 T | 157 T | 196 T | 235 T | 294 T |

| Φ55mm | 11.8 T | 23.7 T | 45.7 T | 71.2 T | 95.0 T | 142 T | 190 T | 237 T | 285 T | 356 T |

| Φ60mm | 14.1 T | 28.2 T | 56.5 T | 84.4 T | 113 T | 169 T | 226 T | 282 T | 339 T | 424 T |

| Φ65mm | 16.5 T | 33.1 T | 66.3 T | 99.5 T | 132 T | 199 T | 265 T | 331 T | 398 T | 497 T |

| Φ70mm | 19.2 T | 38.4 T | 76.9 T | 115 T | 153 T | 230 T | 307 T | 384 T | 461 T | 577 T |

| Φ75mm | 22.0 T | 44.1 T | 88.3 T | 132 T | 176 T | 265 T | 353 T | 441 T | 530 T | 662 T |

| Φ80mm | 25.1 T | 50.2 T | 100 T | 150 T | 201 T | 301 T | 402 T | 502 T | 603 T | 753 T |

| Φ90mm | 31.8 T | 63.6 T | 127 T | 190 T | 254 T | 381 T | 508 T | 636 T | 763 T | 954 T |

| Φ100mm | 39.2 T | 78.5 T | 157 T | 235 T | 314 T | 471 T | 628 T | 785 T | 942 T | 1178 T |

Pressure Matching

| Pressure Diameter | 50 MPa | 100 MPa | 200 MPa | 300 MPa | 400 MPa | 600 MPa | 800 MPa | 1000 MPa | 1200 MPa | 1500 MPa |

| Φ2mm | 0.015 T | 0.03 T | 0.06 T | 0.09 T | 0.12 T | 0.18 T | 0.25 T | 0.31 T | 0.37 T | 0.47 T |

| Φ3mm | 0.035 T | 0.07 T | 0.14 T | 0.21 T | 0.28 T | 0.42 T | 0.56 T | 0.56 T | 0.70 T | 1.06 T |

| Φ4mm | 0.06 T | 0.12 T | 0.25 T | 0.37 T | 0.50 T | 0.75 T | 1.00 T | 1.25 T | 1.50 T | 1.88 T |

| Φ5mm | 0.09 T | 0.19 T | 0.39 T | 0.58 T | 0.78 T | 1.17 T | 1.57 T | 1.96 T | 2.35 T | 2.94 T |

| Φ6mm | 0.14 T | 0.28 T | 0.56 T | 0.84 T | 1.13 T | 1.69 T | 2.26 T | 2.82 T | 3.39 T | 4.24 T |

| Φ7mm | 0.19 T | 0.38 T | 0.76 T | 1.15 T | 1.53 T | 2.23 T | 3.07 T | 3.84 T | 4.61 T | 5.77 T |

| Φ8mm | 0.25 T | 0.50 T | 1.00 T | 1.50 T | 2.01 T | 3.01 T | 4.02 T | 5.02 T | 6.03 T | 7.53 T |

| Φ9mm | 0.31 T | 0.63 T | 1.27 T | 1.90 T | 2.54 T | 3.81 T | 5.08 T | 6.36 T | 7.63 T | 9.54 T |

| Φ10mm | 0.39 T | 0.78 T | 1.57 T | 2.35 T | 3.14 T | 4.71 T | 6.28 T | 7.85 T | 9.42 T | 11.7 T |

| Φ11mm | 0.47 T | 0.95 T | 1.90 T | 2.85 T | 3.80 T | 5.70 T | 7.60 T | 9.50 T | 11.4 T | 14.2 T |

| Φ12mm | 0.56 T | 1.13 T | 2.26 T | 3.39 T | 4.52 T | 6.78 T | 9.04 T | 11.3 T | 13.5 T | 16.9 T |

| Φ13mm | 0.66 T | 1.32 T | 2.65 T | 3.98 T | 5.30 T | 7.96 T | 10.6 T | 13.2 T | 15.9 T | 19.9 T |

| Φ14mm | 0.76 T | 1.53 T | 3.07 T | 4.61 T | 6.15 T | 9.23 T | 12.3 T | 15.3 T | 18.4 T | 23.0 T |

| Φ15mm | 0.88 T | 1.76 T | 3.53 T | 5.30 T | 7.06 T | 10.6 T | 14.1 T | 17.6 T | 21.2 T | 26.5 T |

| Φ16mm | 1.00 T | 2.01 T | 4.02 T | 6.03 T | 8.04 T | 12.0 T | 16.0 T | 20.1 T | 24.1 T | 30.1 T |

| Φ18mm | 1.27 T | 2.54 T | 5.08 T | 7.63 T | 10.1 T | 15.2 T | 20.3 T | 25.4 T | 30.5 T | 38.1 T |

| Φ20mm | 1.57 T | 3.14 T | 6.28 T | 9.42 T | 12.5 T | 18.8 T | 25.1 T | 31.4 T | 37.6 T | 47.1 T |

Enhance your laboratory efficiency with Hench’s advanced Pellet Molding Die Series — precision-engineered for consistent performance and reliable sample preparation.