Vacuum Box Automatic Laboratory Hot Press VHP

Vacuum Box Automatic Laboratory Hot Press VHP Features

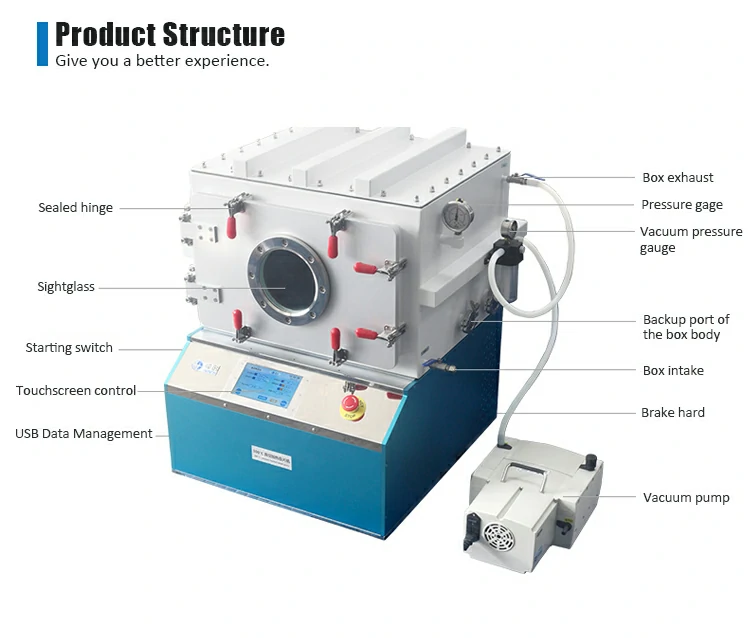

VHP Vacuum automatic hot press is hot press plate and real Close combination of Vacuum housing, vacuum degree up to -0.95Mpa, full Satisfy the user's experimental needs in a vacuum environment.

Product specification

- Explain:Can be customized, optional vacuum pump

- Flushable air source:Helium, neon, argon, nitrogen, krypton, xenon, radon and other inert gases

- High temperature safety:When the die temperature exceeds 50'℃, the thermostat automatically prompts "Pay attention to anti-hot".

- Pressure safety:Program pressure mechanical fault report emergency stop function, automatic pressure relief + emergency stop switch.

- Hot press plate type:Four-column positioning thermal insulation design, upper plate screw suspension design/electroplated polished panel.

- Soaking time:No time limit, reach the set temperature to stop heating.

- Temperature control systenm:Programmable-5-stage heating-automatic heating automatic insulation - natural cooling.

- Touch screen module:Pressure system - Temperature control system - Data management -English interface interchange.

- Control panel:7 inch LCD touch screen/English interface can be switched.

- Die pressure conversion:PCB control program automatically converts to display sample pressure (Mpa). This makes the VHP an advanced vacuum hydraulic press ideal for precise experimental requirements.

- Dwell time:Not limited to N seconds, each period can be set a different pressure holding time.

- Pressurization process:Programmable - 5-stage automatic pressure - automatic pressure retention - precise pressure - timed pressure relief.

Applications

The VHP series hot press is widely used in materials science, chemical synthesis, polymer development, optical films, and resin molding. Its programmable heating and pressurization system makes it one of the most reliable hydraulic press machine options for laboratory environments that demand accuracy and repeatability.

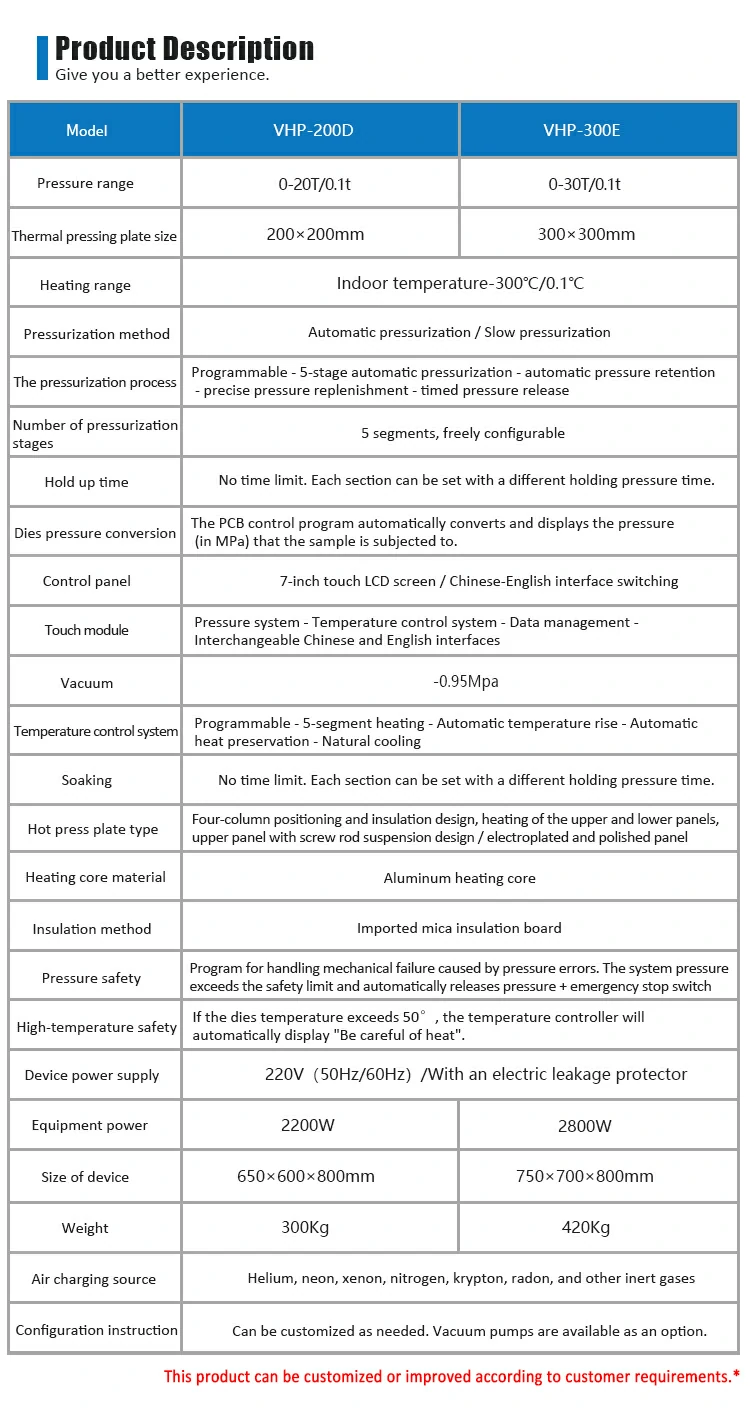

Product Description

| Model | VHP-200D | VHP-300E |

| Pressure range | 0-20T / 0.1t | 0-30T / 0.1t |

| Thermal pressing plate size | 200×200mm | 300×300mm |

| Heating range | Indoor temperature - 300℃ / 0.1℃ | |

| Pressurization method | Automatic pressurization / Slow pressurization | |

| The pressurization process | Programmable - 5-stage automatic pressurization - automatic pressure retention - precise pressure replenishment - timed pressure release | |

| Number of pressurization stages | 5 segments, freely configurable | |

| Hold up time | No time limit. Each section can be set with a different holding pressure time. | |

| Dies pressure conversion | The PCB control program automatically converts and displays the pressure (in MPa) that the sample is subjected to. | |

| Control panel | 7-inch touch LCD screen / Chinese-English interface switching | |

| Touch module | Pressure system - Temperature control system - Data management - Interchangeable Chinese and English interfaces | |

| Vacuum | -0.95Mpa | |

| Temperature control system | Programmable - 5-segment heating - Automatic temperature rise - Automatic heat preservation - Natural cooling | |

| Soaking | No time limit. Each section can be set with a different holding pressure time. | |

| Hot press plate type | Four-column positioning and insulation design, heating of the upper and lower panels, upper panel with screw rod suspension design / electroplated and polished panel | |

| Heating core material | Aluminum heating core | |

| Insulation method | Imported mica insulation board | |

| Pressure safety | Program for handling mechanical failure caused by pressure errors. The system pressure exceeds the safety limit and automatically releases pressure + emergency stop switch | |

| High-temperature safety | If the dies temperature exceeds 50℃, the temperature controller will automatically display "Be careful of heat". | |

| Device power supply | 220V (50Hz/60Hz) / With an electric leakage protector | |

| Equipment power | 2200W | 2800W |

| Size of device | 650×600×800mm | 750×700×800mm |

| Weight | 300Kg | 420Kg |

| Air charging source | Helium, neon, xenon, nitrogen, krypton, radon, and other inert gases | |

| Configuration instruction | Can be customized as needed. Vacuum pumps are available as an option. | |

This product can be customized or improved according to customer requirements.

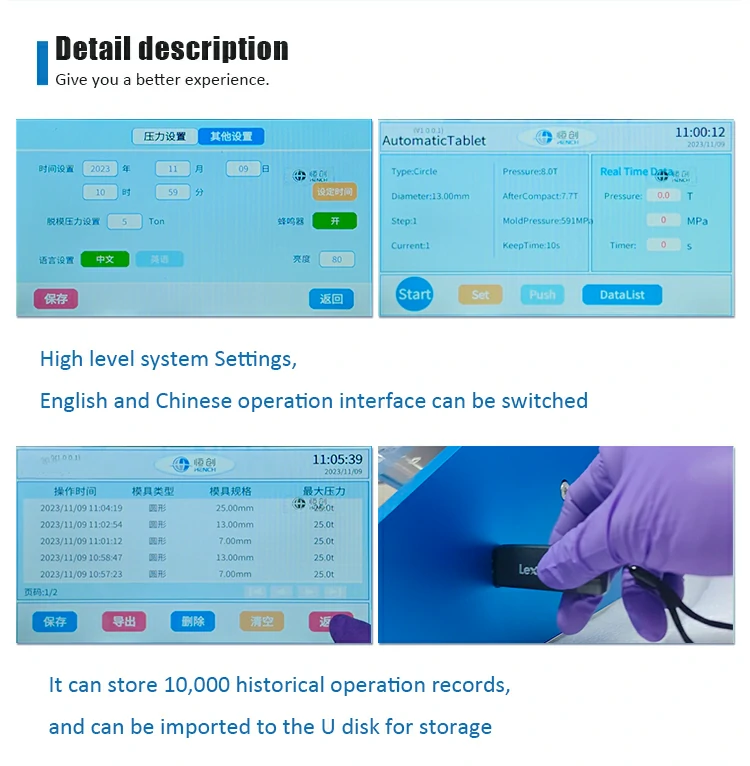

Detail Description

- High-level system settings, with switchable English and Chinese operation interfaces.

- Can store up to 10,000 historical operation records, which can be exported to a USB disk for storage.

Operation Interface

- Setting

Under the operation interface, press Settings to enter the setting interface. Here you can set pressure, mold type, and sample parameters. - Demould

Press the Release button to start. When the pressure exceeds the specified value or the limit switch is triggered, the device will automatically stop and relieve pressure. Manual screw operation is also available. - Data Administration

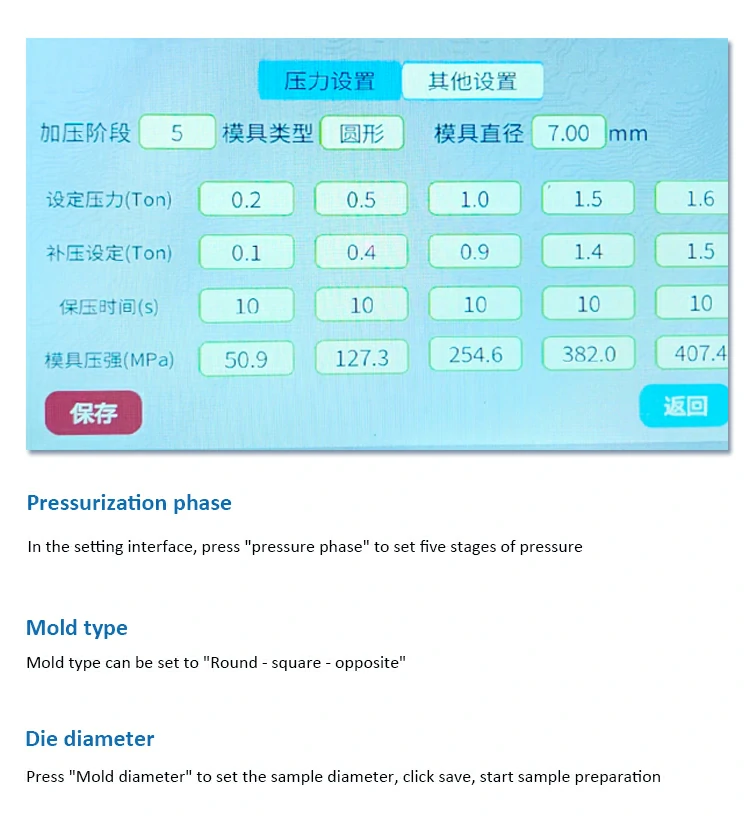

Press Data Management to view experimental parameters and time records. Data can be exported to a USB disk. - Pressurization Phase

In the setting interface, press Pressure Phase to configure up to five stages of pressure. - Mold Type

The mold type can be set to Round, Square, or Opposite. - Die Diameter

Press Mold Diameter to set the sample diameter, then click Save to start sample preparation.

Why Choose Hench?

Hench Technology Co., Ltd., headquartered in Tianjin, China, is a professional manufacturer of laboratory hot presses, infrared sample preparation systems, and customized vacuum press solutions. With over a decade of expertise, Hench has established itself among leading hydraulic press suppliers, offering customers tailored solutions backed by strong R&D and strict quality control.

Hench provides reliable solutions with professional technical support and after-sales service. We emphasizes innovation, safety, and user-friendly design, ensuring that every piece of equipment delivers stable performance for universities, research institutes, and industrial laboratories.