65/100/150/200-ton Modular Automatic Powder Press Machine HAP-FS

Automatic Powder Press Machine Overview

The HAP-FS series is a high-capacity powder press machine designed for laboratories and industrial applications requiring precise and efficient powder pellet preparation. With models ranging from 65 to 200 tons, this modular hydraulic press offers programmable multi-stage pressing, automatic demolding, and a user-friendly interface, ensuring consistent and reproducible results.

Product features

The main application of HAP-FS split automatic split hydraulic press For samples that require high pressure to form,such as ceramics, Metal powder and other large size mold use.Adopt split-type knot structure automatic program operation: program pressure/five stages advanced-Pressure holding-pressure replenishment -timing pressure relief, etc.,using LCD touch scree. The operation is more intuitive and simple.

Automatic control: Savta intelligent program control 5 sections of pressure/optional 15 sections of pressure

Pressure die:Program automatic pressure -automatic pressure -timing pressure - automatic pressure relief

Dwell time:Unlimited time(N seconds)

Pressure conversion:The system automatically converts the sample pressure (overpressure warning)

Device display:7 "touch LCD screen/English interface can be switched

Equipment protection:6.5mm high strength steel plate +6mm Plexiglass protective door

Limit protection:Cylinder above the limit height automatic pressure relief

Host protection:Program pressure mechanical fault report emergency stop function, overpressure automatic pressure relief

Data administration:Can store 10,000 historical operation records, and can be exported to the U disk

Cylinder stroke:50mm

Ejection pressure:The pressure bearing range can be set by itself

Passive safety:Leakage protection + emergency stop switch

Intelligence operation:(Optional) Computer connection for remote operation/can be customized according to customer needs

Applications

The HAP-FS series is ideal for preparing powder pellets for various analytical techniques, including X-ray fluorescence (XRF) and Fourier-transform infrared (FTIR) spectroscopy. Its precise control and consistent performance make it suitable for applications in materials science, environmental testing, and quality control laboratories.

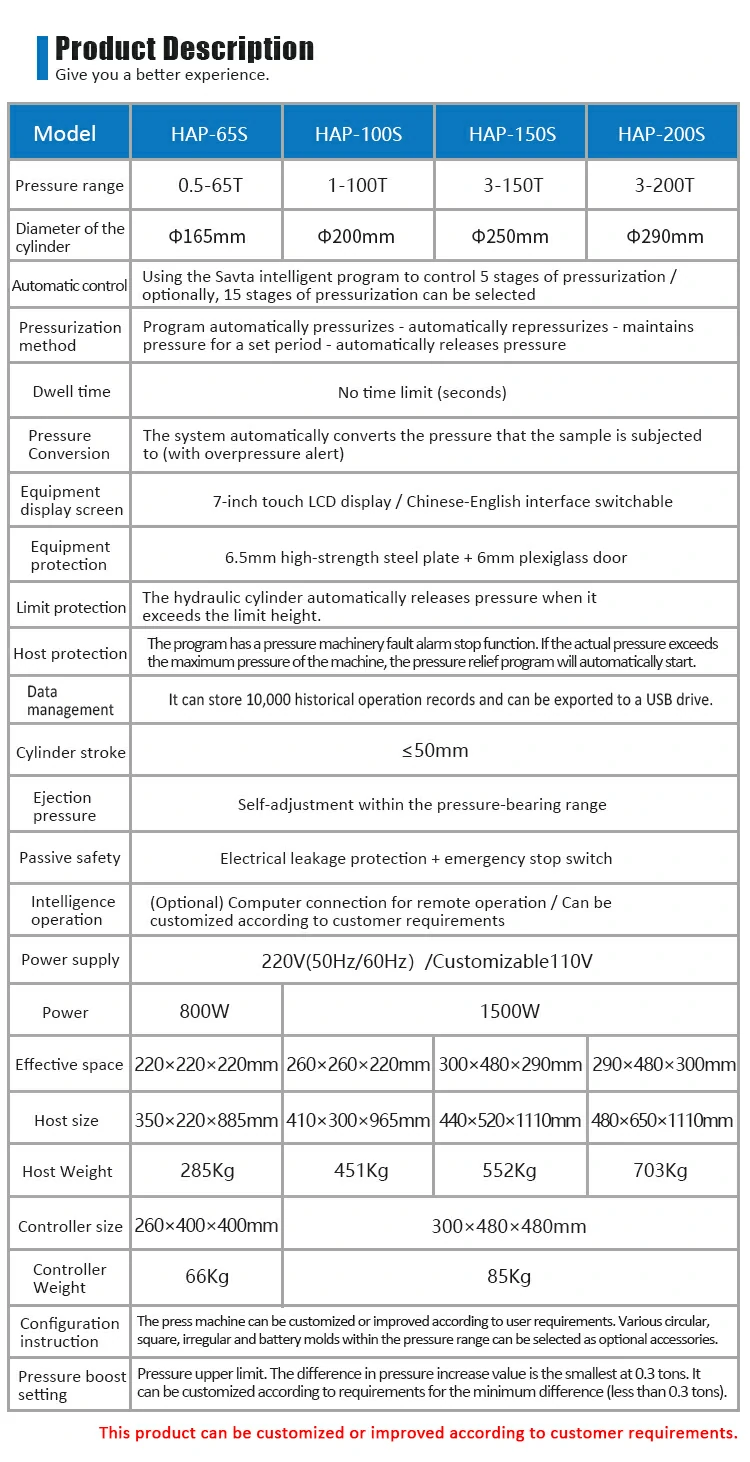

Product Description

| Model | HAP-65S | HAP-100S | HAP-150S | HAP-200S |

| Pressure range | 0.5-65T | 1-100T | 3-150T | 3-200T |

| Diameter of the cylinder | Φ165mm | Φ200mm | Φ250mm | Φ290mm |

| Automatic control | Using the Savta intelligent program to control 5 stages of pressurization / optionally, 15 stages of pressurization can be selected | |||

| Pressurization method | Program automatically pressurizes - automatically repressurizes - maintains pressure for a set period - automatically releases pressure | |||

| Dwell time | No time limit (seconds) | |||

| Pressure Conversion | The system automatically converts the pressure that the sample is subjected to (with overpressure alert) | |||

| Equipment display screen | 7-inch touch LCD display / Chinese-English interface switchable | |||

| Equipment protection | 6.5mm high-strength steel plate + 6mm plexiglass door | |||

| Limit protection | The hydraulic cylinder automatically releases pressure when it exceeds the limit height. | |||

| Host protection | The program has a pressure machinery fault alarm stop function. If the actual pressure exceeds the maximum pressure of the machine, the pressure relief program will automatically start. | |||

| Data management | It can store 10,000 historical operation records and can be exported to a USB drive. | |||

| Cylinder stroke | ≤50mm | |||

| Ejection pressure | Self-adjustment within the pressure-bearing range | |||

| Passive safety | Electrical leakage protection + emergency stop switch | |||

| Intelligence operation | (Optional) Computer connection for remote operation / Can be customized according to customer requirements | |||

| Power supply | 220V(50Hz/60Hz) /Customizable110V | |||

| Power | 800W | 1500W | ||

| Effective space | 220×220×220mm | 260×260×220mm | 300×480×290mm | 290×480×300mm |

| Host size | 350×220×885mm | 410×300×965mm | 440×520×1110mm | 480×650×1110mm |

| Host Weight | 285Kg | 451Kg | 552Kg | 703Kg |

| Controller size | 260×400×400mm | 300×480×480mm | ||

| Controller Weight | 66Kg | 85Kg | ||

| Configuration instruction | The press machine can be customized or improved according to user requirements. Various circular, square, irregular and battery molds within the pressure range can be selected as optional accessories. | |||

| Pressure boost setting | Pressure upper limit. The difference in pressure increase value is the smallest at 0.3 tons. It can be customized according to requirements for the minimum difference (less than 0.3 tons). | |||

This product can be customized or improved according to customer requirements.

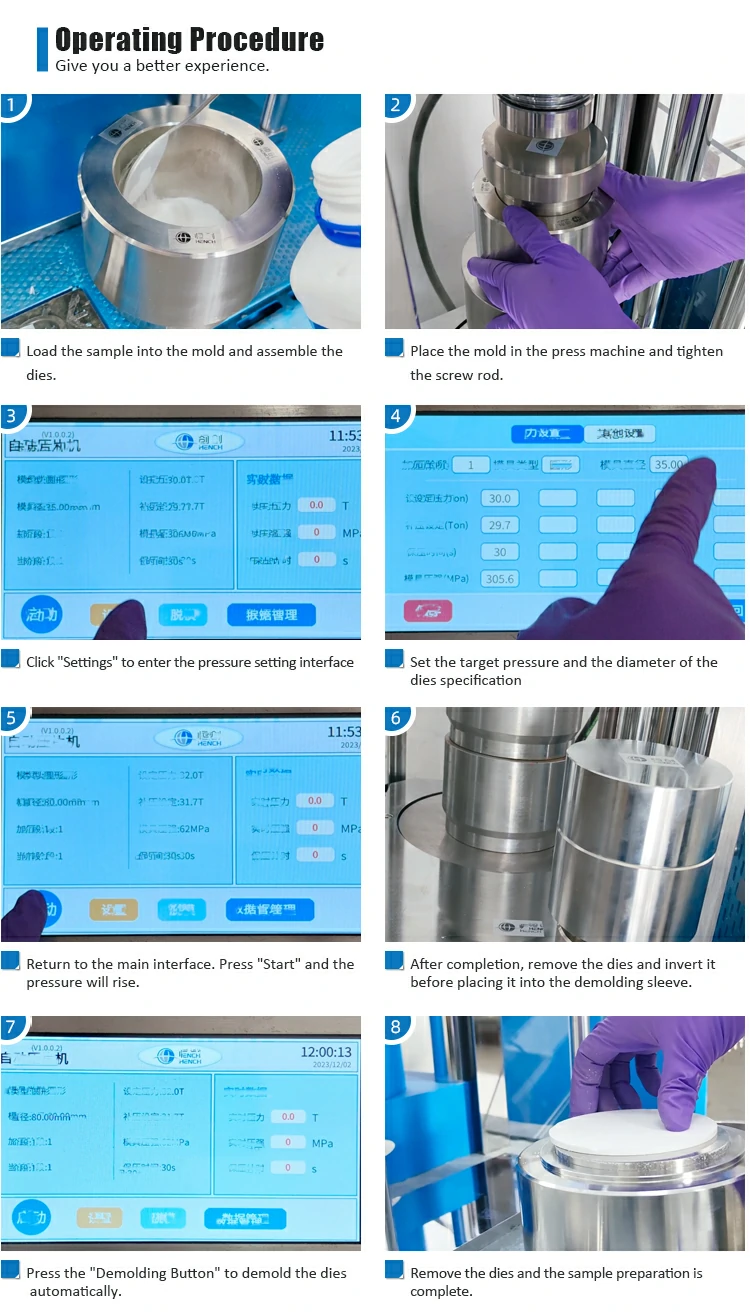

Operating Procedure

-

Load the sample into the mold and assemble the dies.

-

Place the mold in the press machine and tighten the screw rod.

-

Click "Settings" to enter the pressure setting interface.

-

Set the target pressure and the die diameter specification.

-

Return to the main interface and press "Start" to increase the pressure.

-

After completion, remove the dies, invert it, and place it into the demolding sleeve.

-

Press the "Demolding" button to demold the dies automatically.

-

Remove the dies, and the sample preparation is complete.

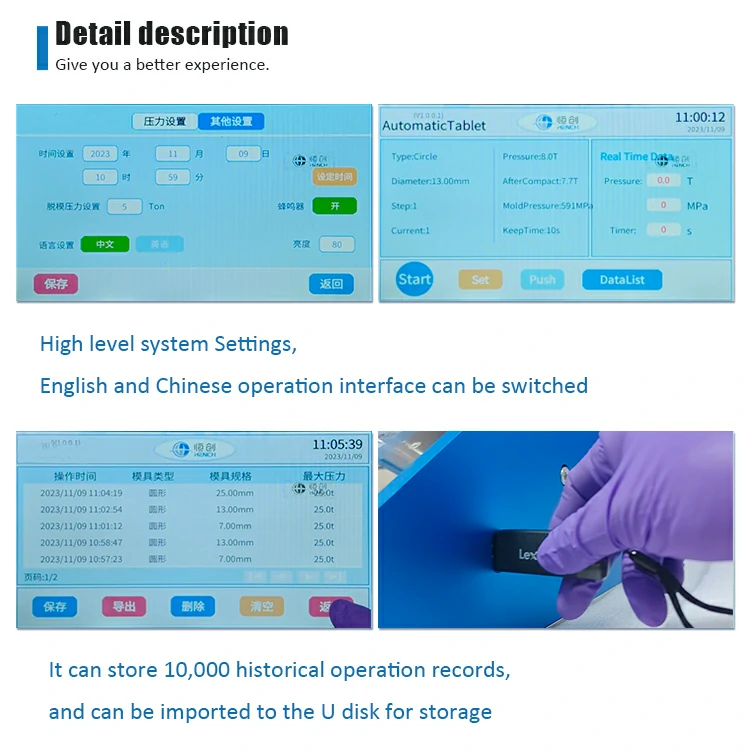

Detail Description

-

High-level system settings, with switchable English and Chinese operation interfaces.

-

Can store up to 10,000 historical operation records, which can be exported to a USB disk for storage.

Operation Interface

-

Setting

Under the operation interface, press Setting to enter the setting interface. Here you can set pressure, mold type, and sample parameters. -

Demould

Press the Release button to start. When the pressure exceeds the specified value or the limit switch is triggered, the device will automatically stop and relieve pressure. Manual screw operation is also available. -

Data Administration

Press Data Management to view experimental parameters and time records. Data can be exported to a USB disk. -

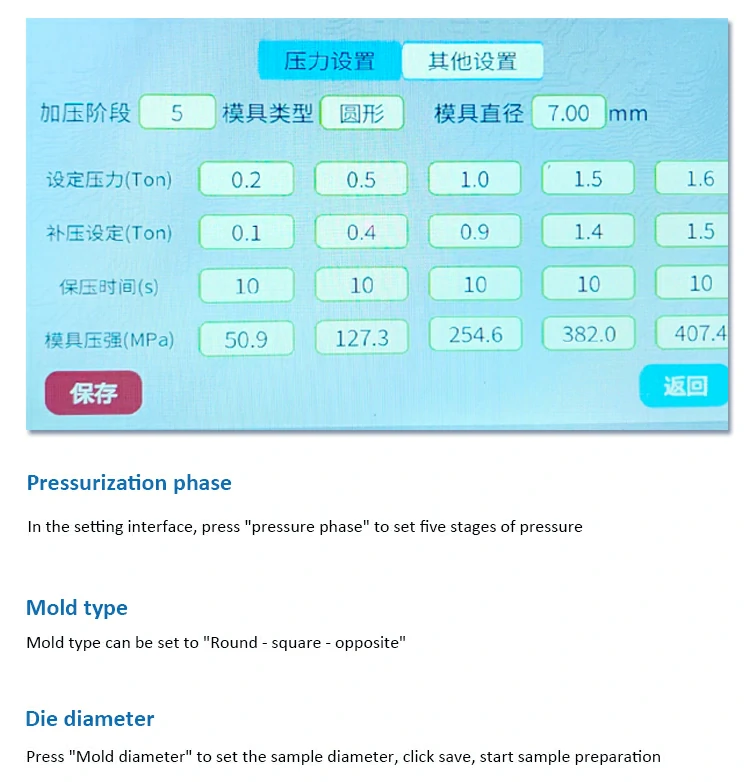

Pressurization Phase

In the setting interface, press Pressure Phase to configure up to five stages of pressure. -

Mold Type

The mold type can be set to Round, Square, or Opposite. -

Die Diameter

Press Mold Diameter to set the sample diameter, then click Save to start sample preparation.

About Hench Technology Co., Ltd.

Hench Technology Co., Ltd., based in Tianjin, China, is a leading hydraulic press supplier specializing in laboratory and industrial pressing solutions. With a commitment to innovation and quality, Hench provides a range of products, including the HAP-FS series, designed to meet the rigorous demands of modern laboratories and industrial applications.