2/10/20/30/40/60-ton Fully Automatic Powder Tablet Press Machine HAP-S

Fully Automatic Powder Tablet Press Machine

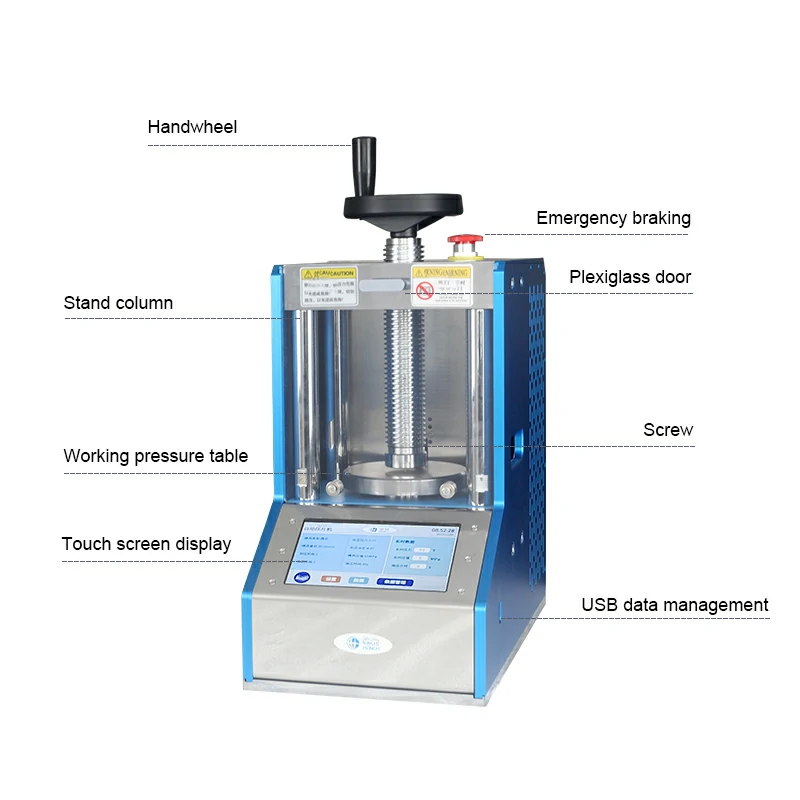

The HAP series automatic hydraulic press with hydraulic drive is mainly used for powder molding sample preparation and is widely applied in X-ray fluorescence, calcium and iron analysis, superconductivity, building materials, ceramics, cement, and other material field research. This product provides precise control to solve the problem of the 6 mm die under the automatic pellet press, and it also meets customers’ multi-stage pressure requirements while incorporating numerous safety features.

Key Features

Advanced Hydraulic Press Technology

At the core of the HAP-30S is its hydraulic press system, which provides uniform pressure distribution across the die, ensuring high-density tablets with minimal variation. This technology is a testament to Hench's commitment to quality and innovation in laboratory equipment. For a broader range of hydraulic solutions, explore our Hydraulic Press Series.

Tailored for Laboratory Excellence

The HAP-30S is meticulously crafted to meet the rigorous demands of laboratory environments. Its compact design, combined with advanced features, makes it an indispensable tool for researchers and technicians seeking reliability and precision. Discover more about our comprehensive lab supplies to enhance your laboratory's capabilities.

Intelligent Control and Safety Features

Equipped with the Savta intelligent program control system, the HAP-30S allows for up to 15 programmable pressure stages, offering flexibility for various sample types. Safety is paramount; the machine includes a 7" touch LCD screen, emergency stop functions, and overpressure protection mechanisms. For those interested in automated solutions, our Automatic Hydraulic Press category provides a range of options to suit diverse needs.

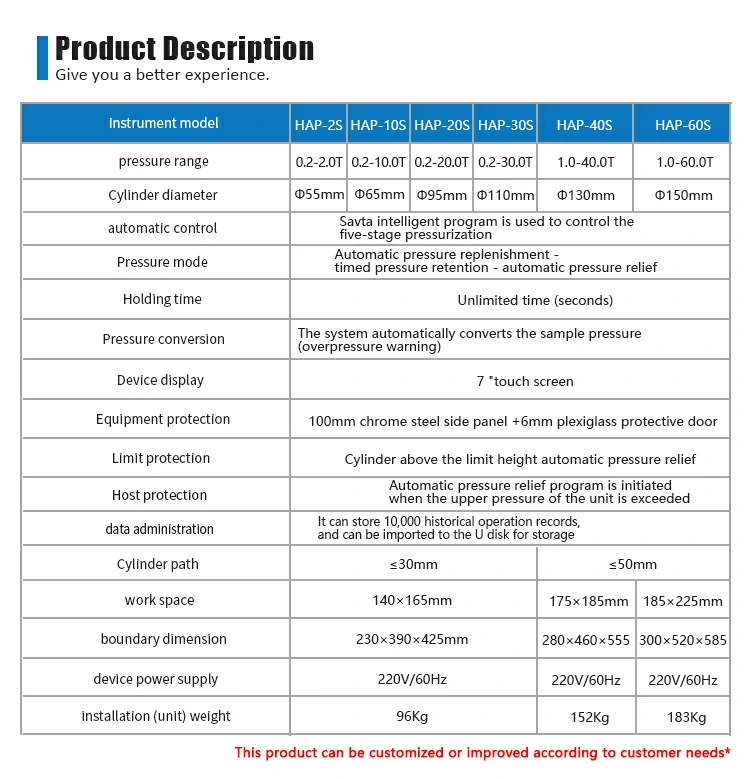

Product Description

| Instrument model | HAP-2S | HAP-10S | HAP-20S | HAP-30S | HAP-40S | HAP-60S |

| pressure range | 0.2-2.0T | 0.2-10.0T | 0.2-20.0T | 0.2-30.0T | 1.0-40.0T | 1.0-60.0T |

| Cylinder diameter | Φ55mm | Φ65mm | Φ95mm | Φ110mm | Φ130mm | Φ150mm |

| automatic control | Savta intelligent program is used to control the five-stage pressurization | |||||

| Pressure mode | Automatic pressure replenishment - timed pressure retention - automatic pressure relief. | |||||

| Holding time | Unlimited time (seconds) | |||||

| Pressure conversion | The system automatically converts the sample pressure (overpressure warning) | |||||

| Device display | 7* touch screen | |||||

| Equipment protection | 100mm chrome steel side panel + 6mm plexiglass protective door | |||||

| Limit protection | Cylinder above the limit height automatic pressure relief | |||||

| Host protection | Automatic pressure relief program is initiated when the upper pressure of the unit is exceeded | |||||

| data administration | It can store 10,000 historical operation records, and can be imported to the U disk for storage | |||||

| Cylinder path | ≤30mm | ≤50mm | ||||

| work space | 140×165mm | 175×185mm | 185×225mm | |||

| boundary dimension | 230×390×425mm | 280×460×555mm | 300×520×585mm | |||

| device power supply | 220V/60Hz | 220V/60Hz | 220V/60Hz | |||

| Installation (unit) weight | 96Kg | 152Kg | 183Kg | |||

This product can be customized or improved according to customer needs*

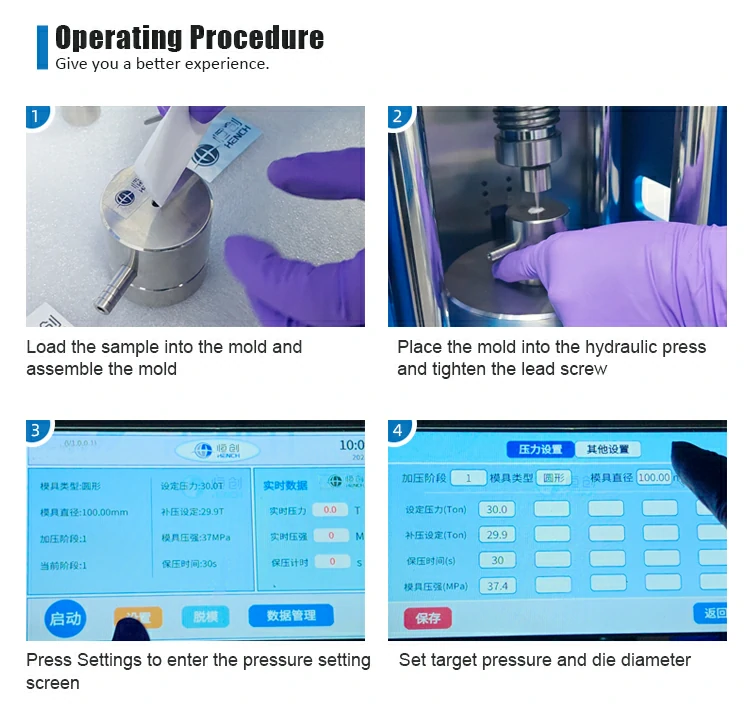

Operating Procedure

-

Load the sample into the mold and assemble the mold.

-

Place the mold into the hydraulic press and tighten the lead screw.

-

Press Setting to enter the pressure setting screen.

-

Set the target pressure and die diameter.

-

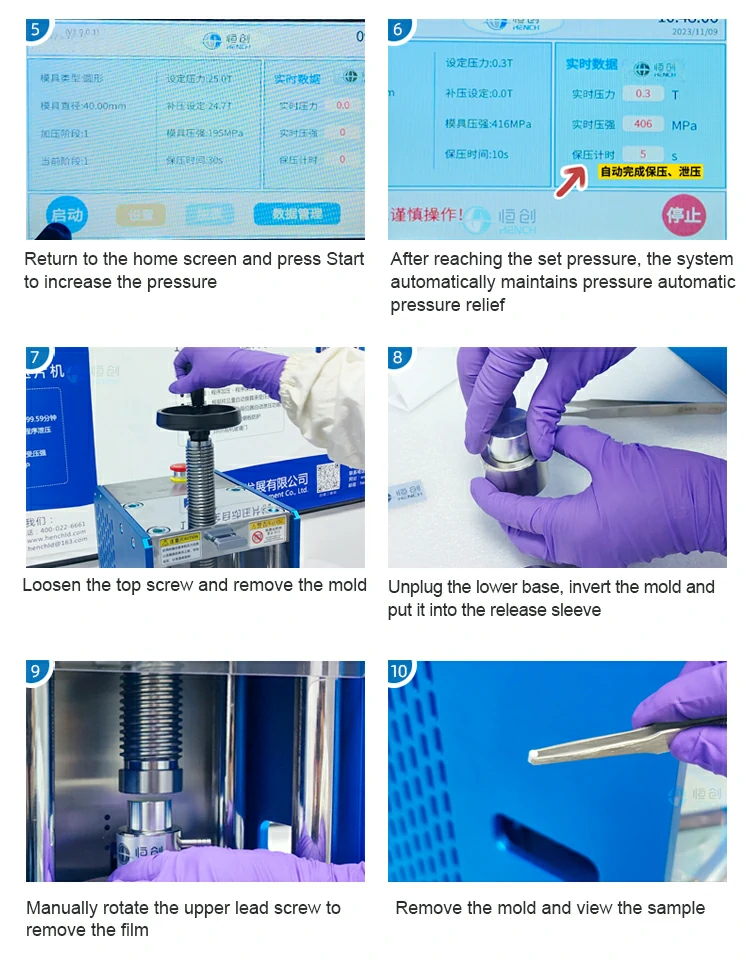

Return to the home screen and press Start to increase the pressure.

-

After reaching the set pressure, the system automatically maintains pressure and then automatically relieves pressure.

-

Loosen the top screw and remove the mold.

-

Unplug the lower base, invert the mold, and place it into the release sleeve.

-

Manually rotate the upper lead screw to remove the film.

-

Remove the mold and check the sample.

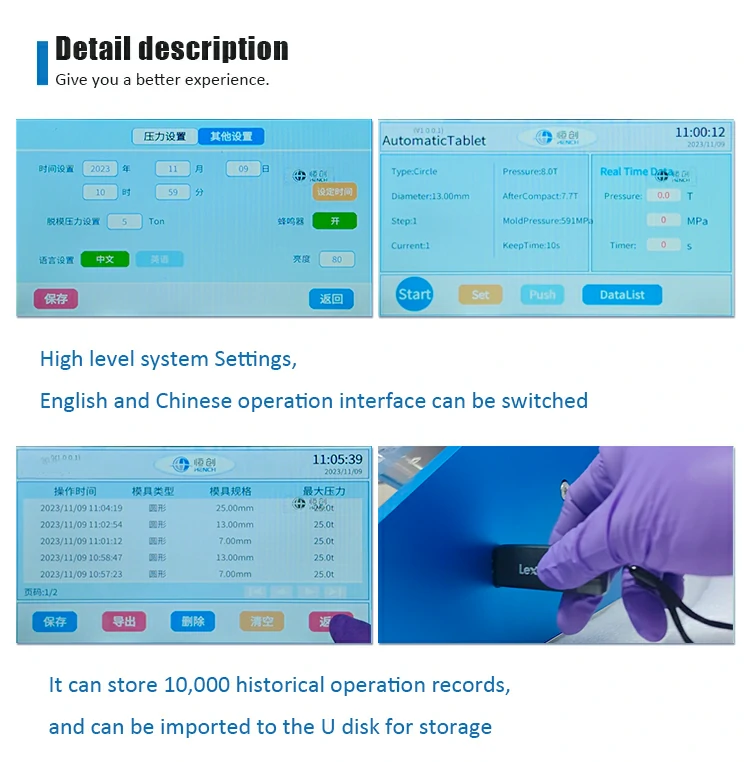

Detail Description

-

High-level system settings, with switchable English and Chinese operation interfaces.

-

Capable of storing 10,000 historical operation records, which can be exported to a USB disk for storage.

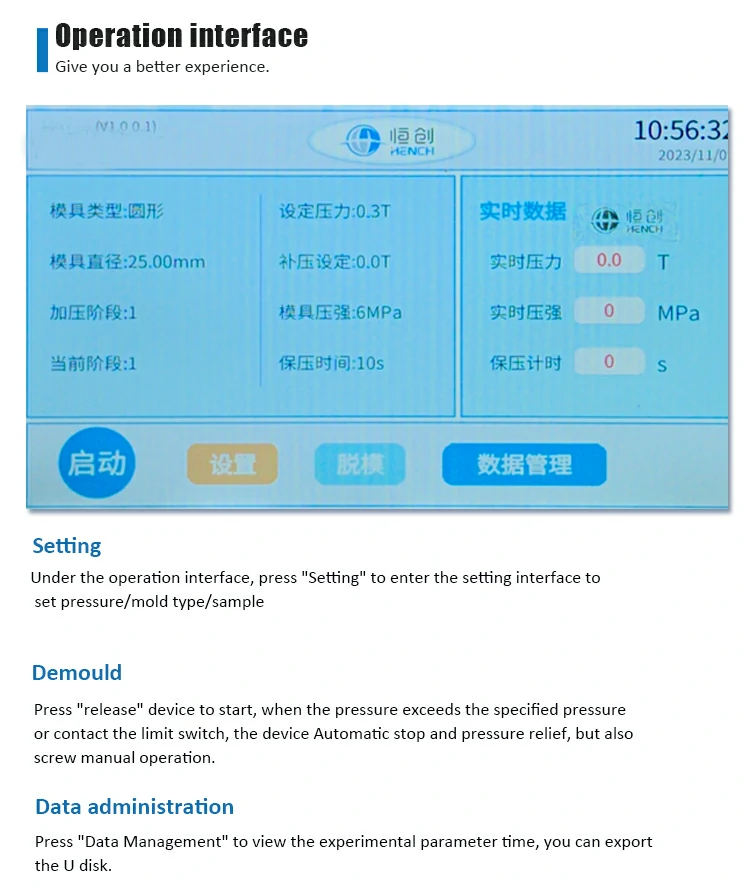

Operation Interface

-

Setting

Under the operation interface, press Setting to enter the setting interface. Here you can set pressure, mold type, and sample parameters. -

Demould

Press the Release button to start. When the pressure exceeds the specified value or the limit switch is triggered, the device will automatically stop and relieve pressure. Manual screw operation is also available. -

Data Administration

Press Data Management to view experimental parameters and time records. Data can be exported to a USB disk. -

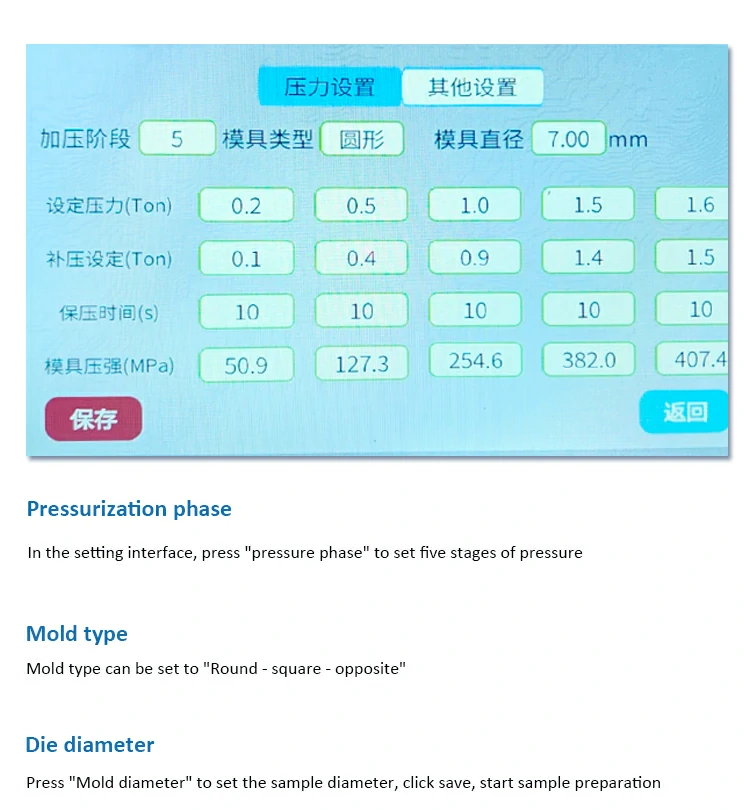

Pressurization Phase

In the setting interface, press Pressure Phase to configure up to five stages of pressure. -

Mold Type

The mold type can be set to Round, Square, or Opposite. -

Die Diameter

Press Mold Diameter to set the sample diameter, then click Save to start sample preparation.

About Hench Technology Co., Ltd.

Hench Technology Co., Ltd. is a leading manufacturer specializing in high-quality laboratory equipment. With a focus on innovation and customer satisfaction, Hench offers a wide array of products, including hydraulic presses and lab supplies, to support scientific research and industrial applications. As trusted hydraulic press suppliers, we are committed to delivering excellence and reliability in every product.