30/40/60-ton Automatic Fluorescent Tablet Hyd Press Machine FTP-X

Automatic Fluorescent Tablet Hyd Press Machine Overview

The FTP-X series is a fully automatic Hyd Press Machine engineered for precise tablet preparation in X-ray fluorescence (XRF) analysis. Its automated pressing and demolding ensure uniform, high-quality pellets, making it ideal for laboratories requiring reproducible results.

Advanced Features

-

Models available in 30T, 40T, and 60T, supporting multi-stage programmable pressing for accuracy.

-

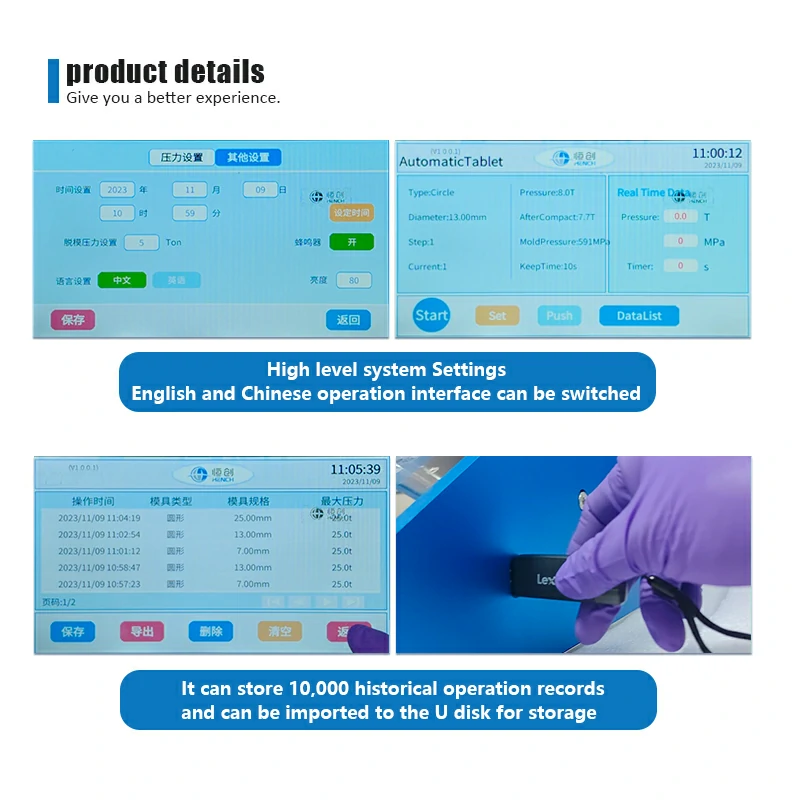

Equipped with a 7" LCD touch screen, enabling intuitive control of pressure, dwell time, and sequence.

-

Molded from 400C high-hardness die steel with quench hardness 85°, ensuring durability and precision.

-

Safety enhanced with a 6 mm plexiglass door and high-strength aluminum oxide plate.

-

Built to integrate smoothly with other lab supplies for research, testing, and quality control workflows.

Applications

Ideal for producing XRF fluorescent tablets in environmental, chemical, or materials science laboratories. The consistent performance reflects the expertise of professional hydraulic press machines designers.

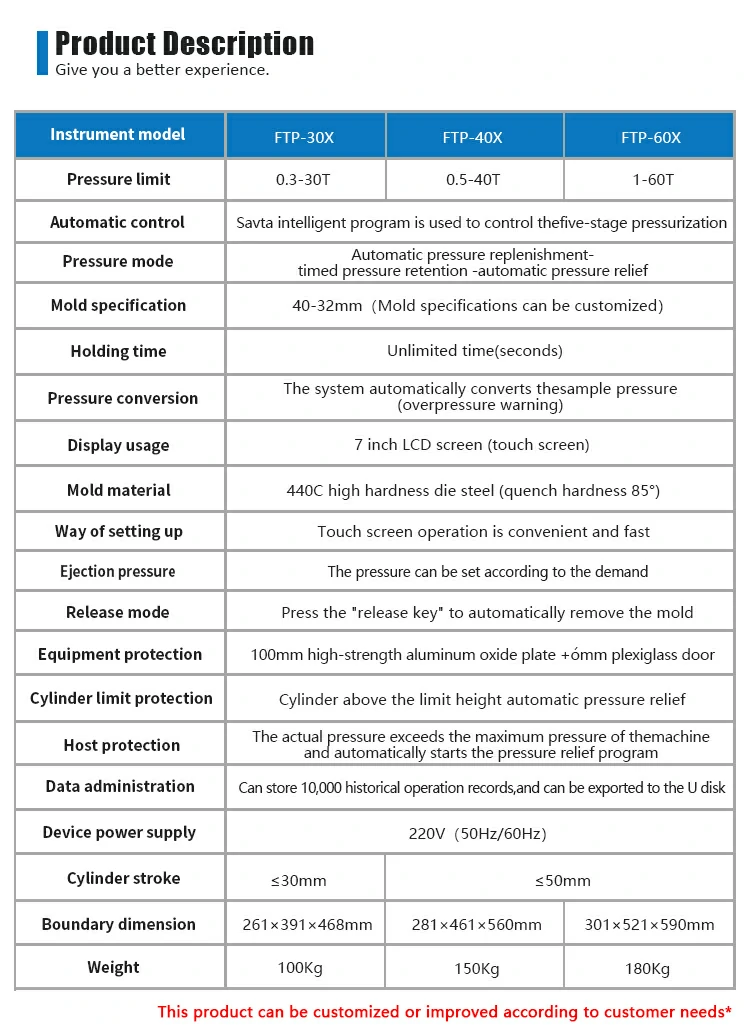

Product Description

| Instrument model | FTP-30X | FTP-40X | FTP-60X |

| Pressure limit | 0.3-30T | 0.5-40T | 1-60T |

| Automatic control | Savta intelligent program is used to control the five-stage pressurization | ||

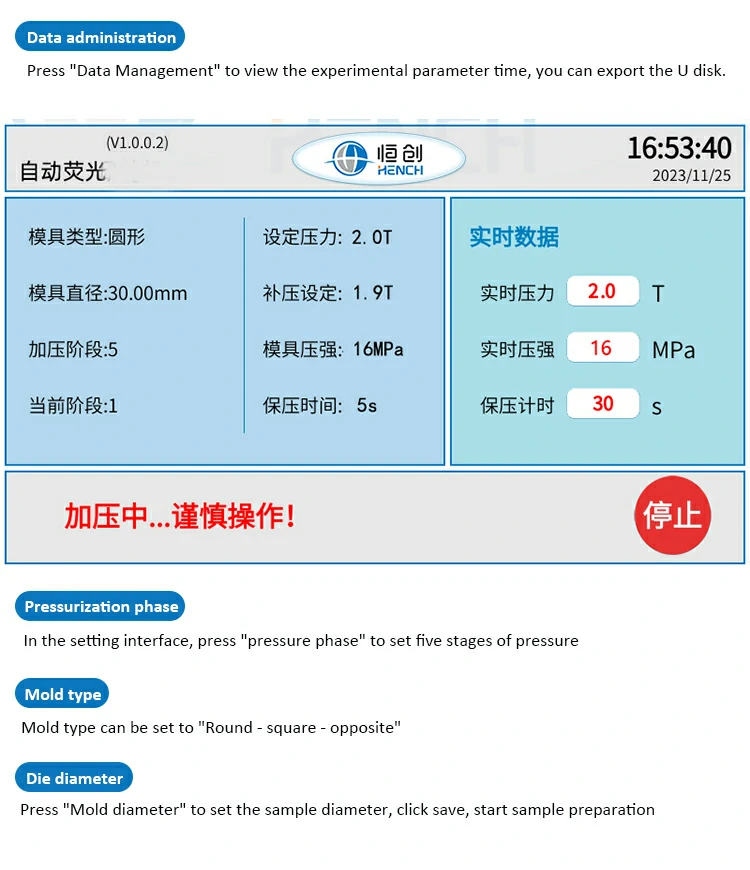

| Pressure mode | Automatic pressure replenishment-timed pressure retention-automatic pressure relief | ||

| Mold specification | 40-32mm (Mold specifications can be customized) | ||

| Holding time | Unlimited time(seconds) | ||

| Pressure conversion | The system automatically converts the sample pressure (overpressure warning) | ||

| Display usage | 7 inch LCD screen (touch screen) | ||

| Mold material | 440C high hardness die steel (quench hardness 85°) | ||

| Way of setting up | Touch screen operation is convenient and fast | ||

| Ejection pressure | The pressure can be set according to the demand | ||

| Release mode | Press the "release key" to automatically remove the mold | ||

| Equipment protection | 100mm high-strength aluminum oxide plate +6mm plexiglass door | ||

| Cylinder limit protection | Cylinder above the limit height automatic pressure relief | ||

| Host protection | The actual pressure exceeds the maximum pressure of the machine and automatically starts the pressure relief program | ||

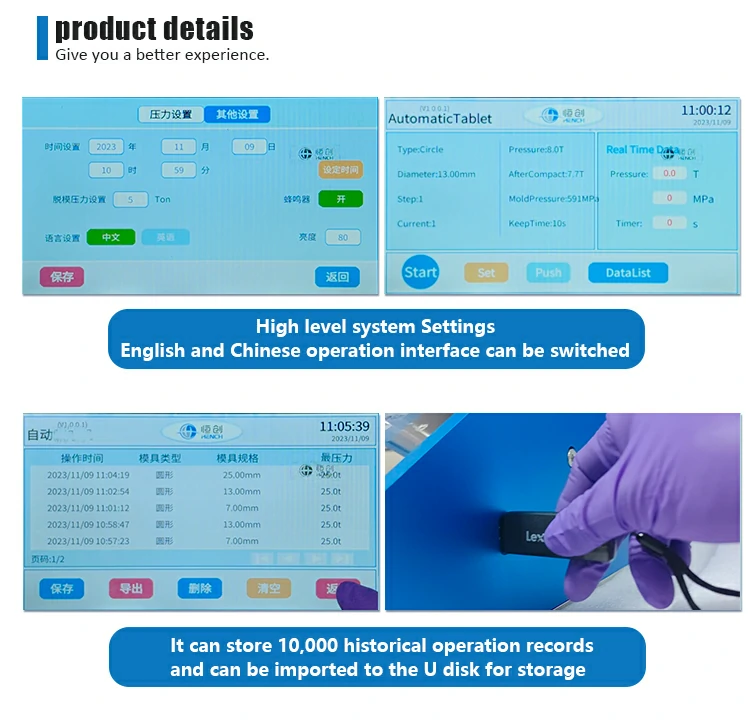

| Data administration | Can store 10,000 historical operation records, and can be exported to the U disk | ||

| Device power supply | 220V (50Hz/60Hz) | ||

| Cylinder stroke | ≤30mm | ≤50mm | |

| Boundary dimension | 261×391×468mm | 281×461×560mm | 301×521×590mm |

| Weight | 100Kg | 150Kg | 180Kg |

This product can be customized or improved according to customer needs*

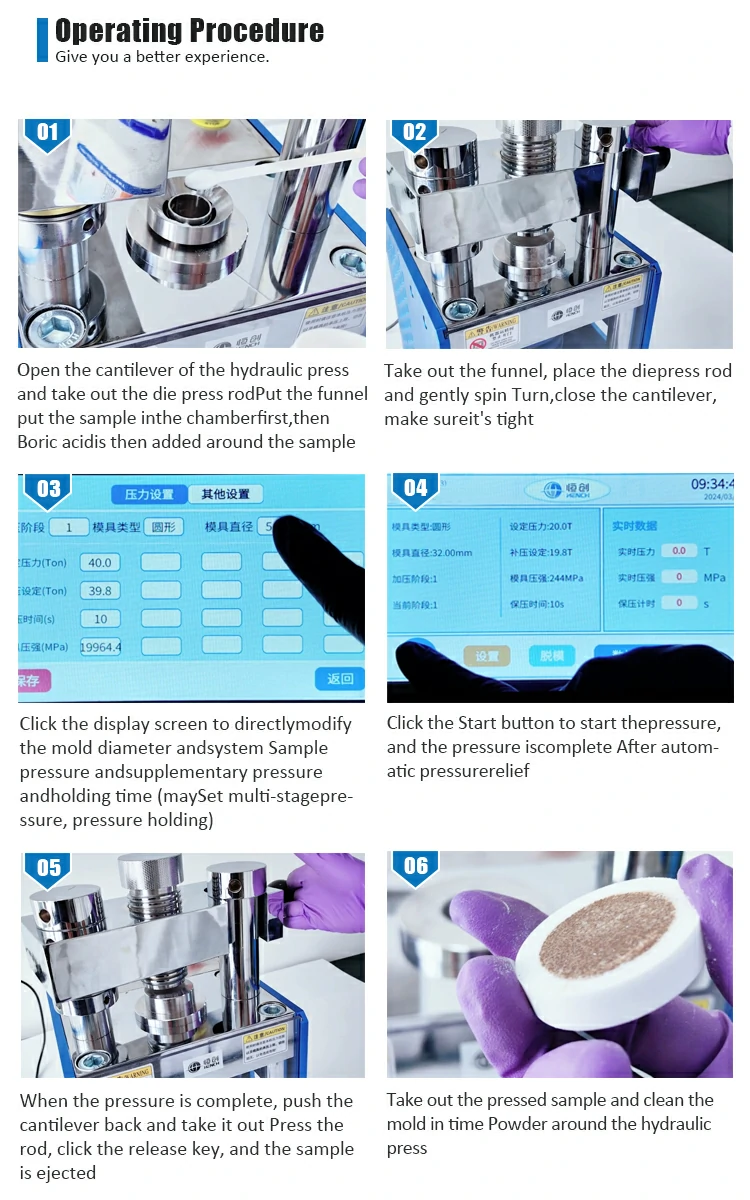

Operating Procedure

-

Open the cantilever of the hydraulic press and take out the die press rod. Insert the funnel, load the sample into the chamber, and then add boric acid around the sample.

-

Remove the funnel, place the die press rod, and gently rotate it. Close the cantilever and ensure it is tightened securely.

-

On the display screen, directly modify the mold diameter, system sample pressure, supplementary pressure, and holding time (multi-stage pressure and pressure holding can be set).

-

Click the Start button to begin pressurization. After reaching the set value, the system will automatically complete pressurization and pressure relief.

-

When pressurization is complete, push back the cantilever and remove the press rod. Click the Release key to eject the sample.

-

Remove the pressed sample and clean the mold promptly, along with any powder around the hydraulic press.

Why Choose Hench?

Hench Technology Co., Ltd., headquartered in Tianjin, China, is a leading hydraulic press supplier specializing in innovative laboratory and industrial presses. Hench’s solutions combine reliability, safety, and ease of use, making them trusted partners for labs worldwide.