Electric Lab Tablet Press 0.2-60 Ton

Automatic Hydraulic Press for Laboratory

HDP Series electric laboratory hydraulic press saves time and effort, and is widely used in fields such as new materials, superconductivity, powder ceramics, new-type power supplies, batteries, building materials and metallurgical powders. It can be seamlessly integrated with analytical instruments including calcium-iron analyzers, infrared spectroscopy (IR) and X-ray fluorescence (XRF) spectrometers.

Specifications

| Parameter | Specification |

| Model | HDP-20 / HDP-30 / HDP-40 / HDP-60S |

| Pressure Range | 0.2-60T (Optional) |

| Accuracy Range | 0.1 T |

| Cylinder Diameter | 130 mm |

| Piston Travel | 50 mm |

| Pressure Dies | Electric PCB program buffer pressure, automatic pressure, manual pressure relief |

| Screen Display | 4.5-inch capacitive touch LCD, English interface |

| Pressure Stability | ≤ 1 MPa / 10 min |

| Overall Structure | Forged, integrated, leak-free design |

| Limit Function | Automatic pressure relief above cylinder limit height |

| Safety Protection | Plexiglass protective door with snap lock |

| Passive Safety | Program pressure mechanical fault reporting, emergency stop, leakage protection |

| Number of Columns | 4 |

| Table Diameter | Φ148 mm |

| Dwell Time | Unlimited (N seconds) |

| Setting Method | Touch screen direct modification (fast and convenient) |

| Power Supply | 220V (50/60Hz), customizable 110V |

| Power | 550 W |

| Effective Space | 145 × 145 × 180 mm |

| Size | 350 × 390 × 625 mm |

| Weight | 111 Kg |

| Special Notes | 30T and above models include protective doors; 220V input voltage, touch screen operation, fast boost voltage |

Hench Lab Hydraulic Press Key Features

-

Durable and Long-Lasting

Our lab pellet press is built with high-quality materials, ensuring it is durable, not easy to rust, and reliable for long-term laboratory use.

-

User-Friendly Operation

The electric hydraulic press design makes it easy to operate, providing intuitive controls for smooth workflow and fast sample preparation.

-

Precise and Reliable Performance

Equipped with advanced mechanisms, the press delivers precise pressure control, guaranteeing consistent and accurate results every time.

-

Practical and Aesthetic Design

Combines beauty and practicality, with a compact, lab-friendly structure suitable for any laboratory environment.

Product Details

-

Precision Control: Handwheel, High-lead Screw, and Rotary Knob.

-

Structure: Heavy-duty Stand Columns and Stable Working Pressure Table.

-

Interface: Digital Touch Screen Display for real-time monitoring.

-

Safety Features: High-transparency Plexiglass Shielding and Emergency Braking (E-stop).

Operating Procedure

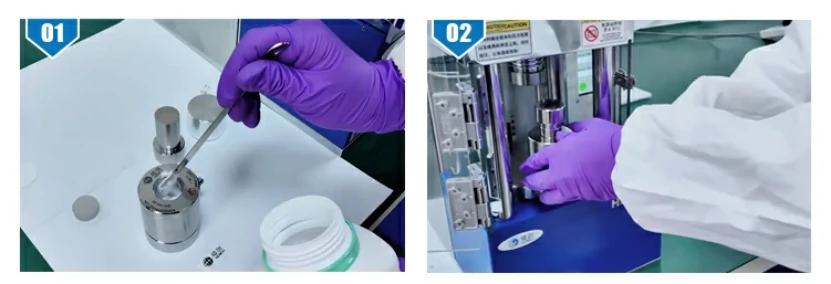

1. Load the sample into the mold and assemble the mold.

2. Place the mold into the hydraulic press and tighten the lead screw.

3. Close the protective door and tighten the side handle.

4. Set the target pressure and refill pressure.

5. Press Start to increase the pressure.

6. Hold the pressure for 30 seconds, then press Stop and loosen the knob to relieve the pressure.

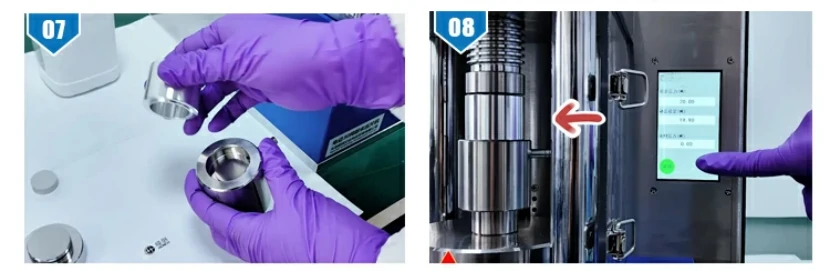

7. Take out the mold, turn it upside down, pull out the base, and insert the release sleeve.

8. Press Start to withdraw the film.

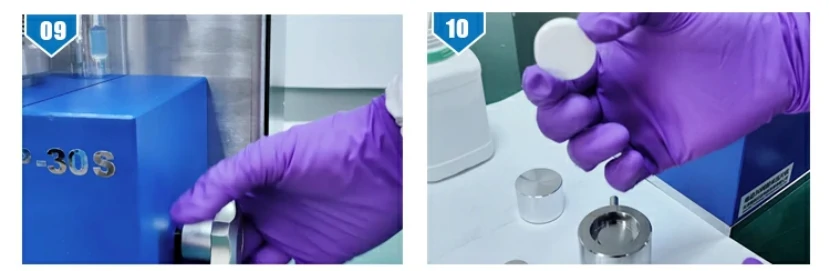

9. When the die releases, press Stop and loosen the knob.

10. Remove the mold and check the sample.

About Hench Technology Co., Ltd.

Hench Technology Co., Ltd. is a leading manufacturer specializing in high-quality laboratory pellet press. With a focus on innovation and customer satisfaction, Hench offers a wide array of products, including hydraulic press machine and lab supplies, to support scientific research and industrial applications. As trusted hydraulic press suppliers, we are committed to delivering excellence and reliability in every product. Contact us for the latest laboratory hydraulic press price!