2/3/5/12/15-ton Manual Pointer Hydraulic Presses Machine YP

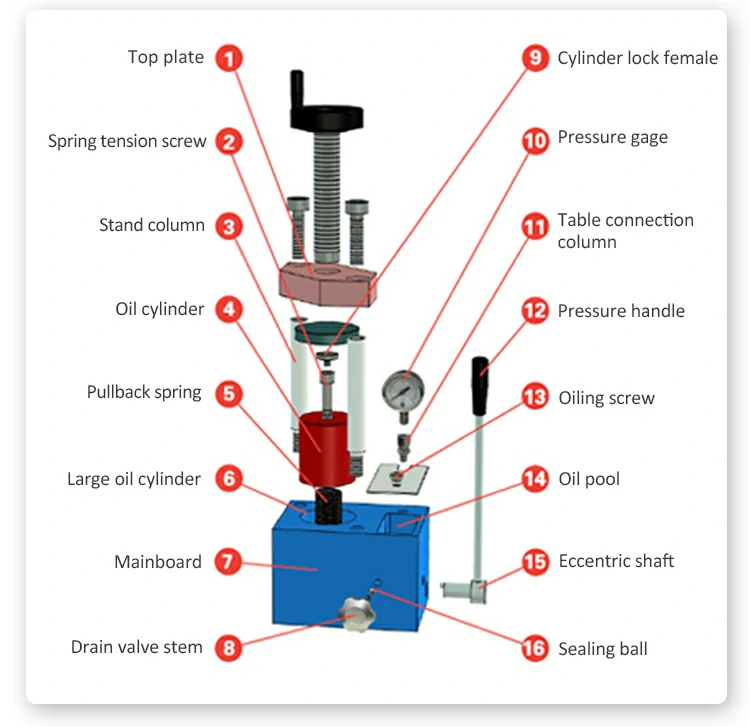

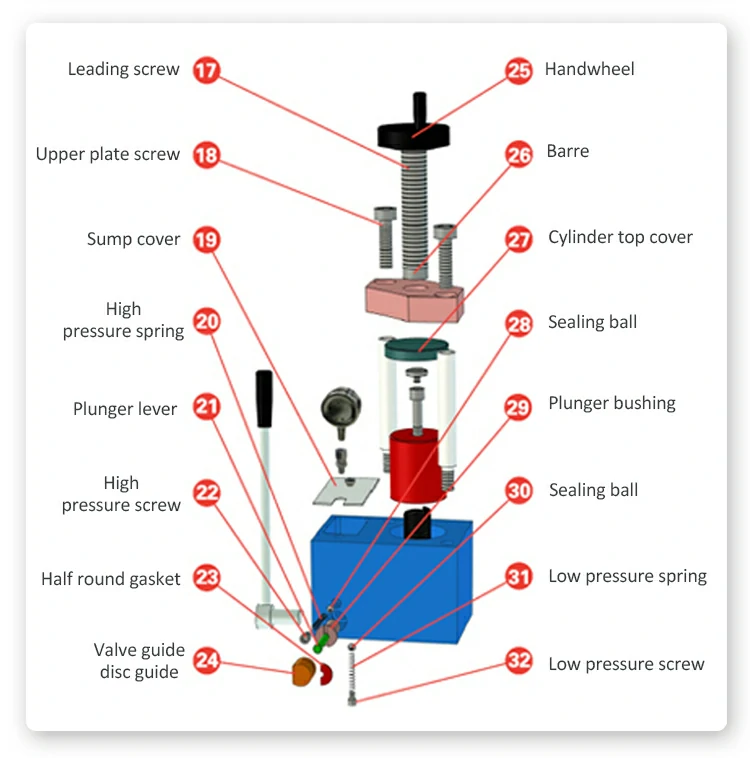

Configuration Instruction of Manual Pointer Hydraulic Presses Machine

According to customer requirements, the columns can be made taller. Various types of circular, square and irregular shapes within the pressure-bearing range can be selected.

Battery molds, etc.

Optimized for Research Environments

The YP Series is designed for laboratory reliability:

-

Pointer pressure gauge with dual scale (Tons/MPa) for precise readings.

-

Integrated cylinder and piston construction minimizes leakage and enhances durability.

-

Compact build makes it suitable for glove box use or space-limited labs.

For extended applications, Hench also supplies other hydraulic press machines covering a wider capacity range.

Built-In Safety Measures

-

Overpressure stability tested within ±1 MPa over 10 minutes.

-

Strong protective housing reduces risks during operation.

-

Mechanical design ensures smooth, stable pressing performance.

Complete Laboratory Support

Alongside presses, Hench delivers comprehensive lab supplies including dies, molds, and accessories for sample preparation. This ensures researchers can build a reliable and efficient laboratory setup.

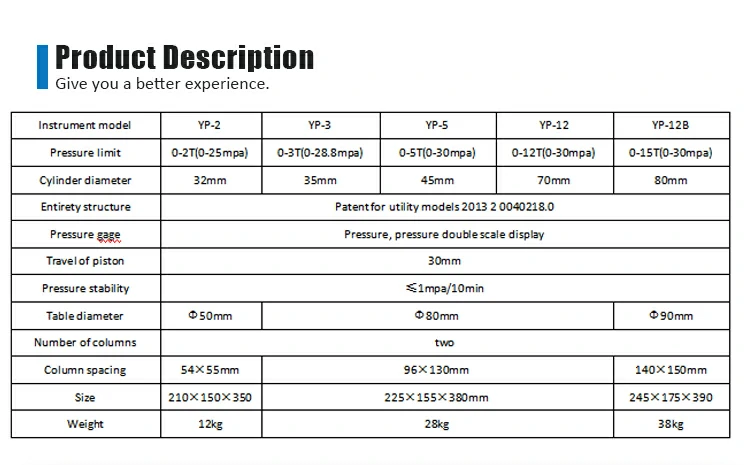

Product Description

| Instrument model | YP-2 | YP-3 | YP-5 | YP-12 | YP-12B |

| Pressure limit | 0-2T(0-25mpa) | 0-3T(0-28.8mpa) | 0-5T(0-30mpa) | 0-12T(0-30mpa) | 0-15T(0-30mpa) |

| Cylinder diameter | 32mm | 35mm | 45mm | 70mm | 80mm |

| Entirety structure | Patent for utility models 2013 2 0040218.0 | ||||

| Pressure gage | Pressure, pressure double scale display | ||||

| Travel of piston | 30mm | ||||

| Pressure stability | ≤1mpa/10min | ||||

| Table diameter | Φ50mm | Φ80mm | Φ90mm | ||

| Number of columns | two | ||||

| Column spacing | 54×55mm | 96×130mm | 140×150mm | ||

| Size | 210×150×350 | 225×155×380mm | 245×175×390 | ||

| Weight | 12kg | 28kg | 38kg | ||

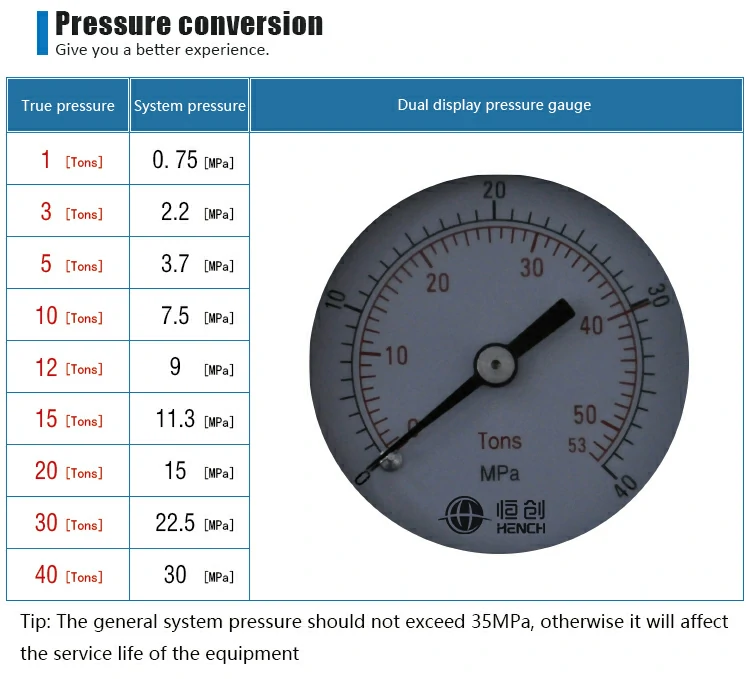

Pressure Conversion

| True pressure | System pressure |

| 1 Tons | 0.75 MPa |

| 3 Tons | 2.2 MPa |

| 5 Tons | 3.7 MPa |

| 10 Tons | 7.5 MPa |

| 12 Tons | 9 MPa |

| 15 Tons | 11.3 MPa |

| 20 Tons | 15 MPa |

| 30 Tons | 22.5 MPa |

| 40 Tons | 30 MPa |

Tip: The general system pressure should not exceed 35MPa, otherwise it will affect the service life of the equipment.

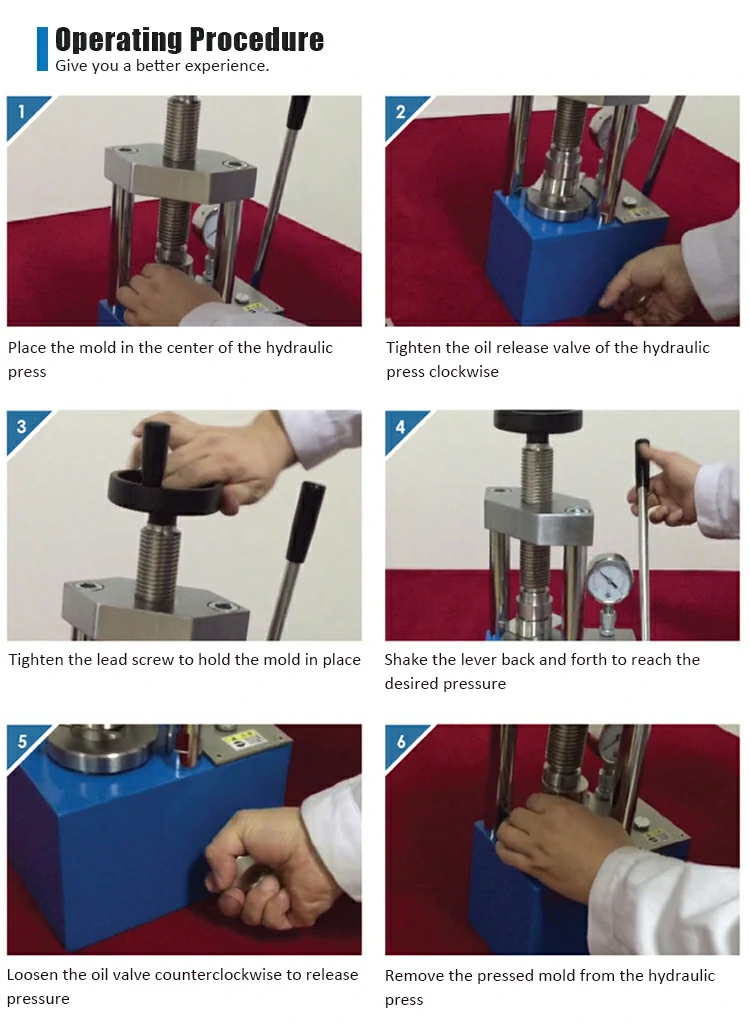

Operating Procedure

-

Place the mold in the center of the hydraulic press.

-

Tighten the oil release valve of the hydraulic press clockwise.

-

Tighten the lead screw to secure the mold in place.

-

Shake the lever back and forth until the desired pressure is reached.

-

Loosen the oil release valve counterclockwise to release the pressure.

-

Remove the pressed mold from the hydraulic press.

Why Choose Hench

As established hydraulic press suppliers, Hench combines technical expertise with a commitment to quality. Their presses are widely used by universities, research institutions, and industrial laboratories worldwide, ensuring consistent results.

[caption id="attachment_4761" align="alignnone" width="800"]